Hi Lads

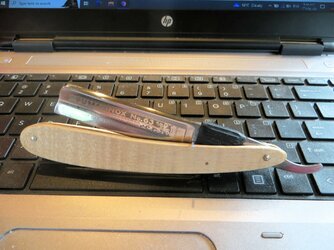

I have always wanted a Puma razor and today I acquired a beautiful Puma-Inox No63, blade only and no scales. I am a fairly decent woodworker with a full wood shop and have made scales before. I intend to rescale this razor using a figured wood that is close to the original Puma ivory color. I'm hoping to find a suitable pen blank. I intend to use 3 pins.

My question is, how are the scales shaped to clear the rubber sleeve that is on the tang? The rubber on my blade is in good condition so I intend to keep it. Are the scales cleared to avoid the rubber or are there extra thick washers at the pivot pin? If anyone could attach a photo of the area in question I would be eternally grateful.

I have always wanted a Puma razor and today I acquired a beautiful Puma-Inox No63, blade only and no scales. I am a fairly decent woodworker with a full wood shop and have made scales before. I intend to rescale this razor using a figured wood that is close to the original Puma ivory color. I'm hoping to find a suitable pen blank. I intend to use 3 pins.

My question is, how are the scales shaped to clear the rubber sleeve that is on the tang? The rubber on my blade is in good condition so I intend to keep it. Are the scales cleared to avoid the rubber or are there extra thick washers at the pivot pin? If anyone could attach a photo of the area in question I would be eternally grateful.