- Thread starter

- #521

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gillette Slim Disassembly/Reassembly w/ before and after photos

- Thread starter Captain Murphy

- Start date

- Thread starter

- #522

Hey CAP, when you took mine apart, how bad was it?

- Thread starter

- #524

Awesome! I would have thought there would have been a lot more crap in it considering the trouble I had moving through the settings when I first got it.

I can't wait for this one to get back!

I can't wait for this one to get back!

Good evening, Cap. Do you have any fixes for a stripped TTO slider on a Slim? I have two, and both of the the threaded sliders (I don't know what else to call them) are partially stripped. When you thread it in to the TTO knob, once it bottoms out, you can just keep turning it. When the razor is assembled, the doors will close, but then cannot be tightened, and the TTO knob will just continue to turn. As best as I can tell, the threads inside the TTO knob are OK.

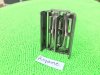

Here is a photo of the offending part:

I was thinking about trying to do some type of thread "repair" using a high performance epoxy like PC-7, MarineTex, or one the epoxies that has included metal. The more I think about that, the less enthused I become, as I am not sure that such a repair would stand up to the repetitive opening and closing with the required force necessary for proper function. Before I start experimenting, I thought I would ask the master (that's you!) if he has any secrets to share. The obvious solution is to replace it with a good part from another razor, but those are not easy to come by.

Thanks,

Matt

Here is a photo of the offending part:

I was thinking about trying to do some type of thread "repair" using a high performance epoxy like PC-7, MarineTex, or one the epoxies that has included metal. The more I think about that, the less enthused I become, as I am not sure that such a repair would stand up to the repetitive opening and closing with the required force necessary for proper function. Before I start experimenting, I thought I would ask the master (that's you!) if he has any secrets to share. The obvious solution is to replace it with a good part from another razor, but those are not easy to come by.

Thanks,

Matt

- Thread starter

- #527

Matt,

Although I have seen this before, it is not very common with the slims and super adjustables. It must have taken a lot of wear and abrasion to break down the edges of them threads. I remember reading the patent descriptions on the slim but I cannot recall what type of threads those are referred to. Anyways, I am not sure how fruitful a marine epoxy repair would be or any other kind of thread recreation. I agree with you 100% that the easiest way to go about this would be just to swap it out.

Luckily, the fine gentlemen of B&B have been sending me some pretty hurt SA's and slims so I think I have one we can swap out with that old worn out one of yours

Feel free to PM me and we can go from there Interesting content to show in the thread anyhow, thanks for posting!

Interesting content to show in the thread anyhow, thanks for posting!

Although I have seen this before, it is not very common with the slims and super adjustables. It must have taken a lot of wear and abrasion to break down the edges of them threads. I remember reading the patent descriptions on the slim but I cannot recall what type of threads those are referred to. Anyways, I am not sure how fruitful a marine epoxy repair would be or any other kind of thread recreation. I agree with you 100% that the easiest way to go about this would be just to swap it out.

Luckily, the fine gentlemen of B&B have been sending me some pretty hurt SA's and slims so I think I have one we can swap out with that old worn out one of yours

Feel free to PM me and we can go from there

Interesting content to show in the thread anyhow, thanks for posting!

Interesting content to show in the thread anyhow, thanks for posting!Matt,

Although I have seen this before, it is not very common with the slims and super adjustables. It must have taken a lot of wear and abrasion to break down the edges of them threads. I remember reading the patent descriptions on the slim but I cannot recall what type of threads those are referred to. Anyways, I am not sure how fruitful a marine epoxy repair would be or any other kind of thread recreation. I agree with you 100% that the easiest way to go about this would be just to swap it out.

Luckily, the fine gentlemen of B&B have been sending me some pretty hurt SA's and slims so I think I have one we can swap out with that old worn out one of yours

Feel free to PM me and we can go from thereInteresting content to show in the thread anyhow, thanks for posting!

Wow!!! Not only the good captain offering his services.... Again...

Now this is a community I'm proud to be a part of!!!

- Thread starter

- #529

- Thread starter

- #530

Wow, Cap!! She looks brand new!

Afternoon Cap. I have a quick question about the gap setting. I have checked a few slims gap on number 5 before disassembly and they measure 0.635mm (0.025 ). I'm just double checking the factory setting that I have of 0.813 at number 5. Do I have it right? It seems the gap is more aggressive with the correct gap.

Hi Cap,

Both two tone Black Rhodium/Rose Gold Slims arrived today.. they look amazing Sir!

Was a bit worried there, been in transit twice as long as your last shipment hat had to compete with the xmas rush, though better late than never.

Found out today that the '66 actually is the birth year of one of my half brothers, so will be wrapping that one up for my father's birthday.

The '64 will be added to my rotation from tomorrow.

Thanks again to you & Chris from Razorplate.

Both two tone Black Rhodium/Rose Gold Slims arrived today.. they look amazing Sir!

Was a bit worried there, been in transit twice as long as your last shipment hat had to compete with the xmas rush, though better late than never.

Found out today that the '66 actually is the birth year of one of my half brothers, so will be wrapping that one up for my father's birthday.

The '64 will be added to my rotation from tomorrow.

Thanks again to you & Chris from Razorplate.

- Thread starter

- #534

Glad you liked it, Sir!Wow, Cap!! She looks brand new!

Yes sir! 0.813 mm should be equivalent to 0.032 in.Afternoon Cap. I have a quick question about the gap setting. I have checked a few slims gap on number 5 before disassembly and they measure 0.635mm (0.025 ). I'm just double checking the factory setting that I have of 0.813 at number 5. Do I have it right? It seems the gap is more aggressive with the correct gap.

Awesome news, Sir! I am glad they made it...we were both sweating that one outHi Cap,

Both two tone Black Rhodium/Rose Gold Slims arrived today.. they look amazing Sir!

Was a bit worried there, been in transit twice as long as your last shipment hat had to compete with the xmas rush, though better late than never.

Found out today that the '66 actually is the birth year of one of my half brothers, so will be wrapping that one up for my father's birthday.

The '64 will be added to my rotation from tomorrow.

Thanks again to you & Chris from Razorplate.

- Thread starter

- #535

So apparently I lost the before photos of this slim or something (I usually don't lose any shots that I take of these restoration projects but they have vanished! These before shots were good too...man oh man was there some sweet crud. Anyways, here are the before photos (not mine) of a slim that has been with Chris @RazorPlate:

- Thread starter

- #536

- Thread starter

- #537

- Thread starter

- #538

That is one slick looking razor, indeed! Excellent job by everyone!

Similar threads

- Replies

- 16

- Views

- 2K

She was pretty clean!

She was pretty clean!