Yep This ^^^If it's shot, then it's shot.

But sometimes some people think it's shot when it isn't.

Maybe try cleaning it with a very stiff tooth brush and scouring powder.

I lap a lot quite often, I have to clean my plates off regularly or they slow down. I use Barkeepers Friend powder, you prob don't have that available but I am sure there is an equivalent.

I also have a very old 400x that is very tired. I don't use it for making slurry, last thing I want is a diamond nub popping off into my finishing slurry. Yes, it happens. If I want slurry, I'll use a slurry stone.

But - for final finish lapping of just about any stone - the beat up 400 Atoma works great.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cheap diamond plates for lapping

- Thread starter Legion

- Start date

- Thread starter

- #22

I went with this option, so the wait begins.I like the lapidary plates if i am looking for coarse and cheap. Just contact cement to a flat backing. The definitely last longer then the rectangular honeycomb plates. I have also tried the 120/180 plates with the diagonal groves. One was mounted to plastic one was aluminum, both where not even close to flat.

I was able to get a 30cm diameter disk in 240 grit for about $60AU, posted.

Still cheaper than the cheapest $45 US replacement Atoma 400 i found on Amazon.

After the conversion, that would be 41 EUR. Problem is an Atoma replacement sheet sells for 65 EUR over here.Still cheaper than the cheapest $45 US replacement Atoma 400 i found on Amazon.

- Thread starter

- #25

Still cheaper than the cheapest $45 US replacement Atoma 400 i found on Amazon.

And about $85AU here. If the lapping disk matches up in performance and longevity, then I am well in front based on the size. Worth a try, anyway.After the conversion, that would be 41 EUR. Problem is an Atoma replacement sheet sells for 65 EUR over here.

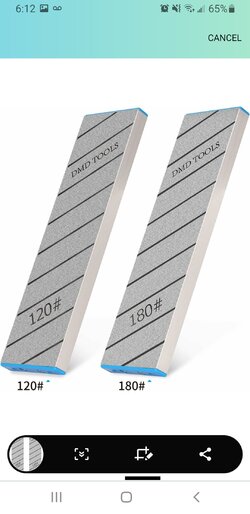

DMD diamond stones got some friends here around. Not much feedback, but cutting reliable with little wear.

Now DMD offers diamond plates. There is a first look at german Messerforum:

Just checked the low grit with a straight edge (Haarlineal). Its concave from end to end, definitely more than my Diaflat. Hhmmmm, .

I didn't ecpect that. And so far I can not tell how deep the concave is.

Now DMD offers diamond plates. There is a first look at german Messerforum:

Vorstellung DMD Kombi-Diamantplatte 400/1200 mit Schliffbildern

Of course no one knows how long this plates last. But I took a 150/400 and 400/1000....Just checked the low grit with a straight edge (Haarlineal). Its concave from end to end, definitely more than my Diaflat. Hhmmmm, .

I didn't ecpect that. And so far I can not tell how deep the concave is.

My experience with this still dmd had the same problem. Gets worse with pressure.DMD diamond stones got some friends here around. Not much feedback, but cutting reliable with little wear.

Now DMD offers diamond plates. There is a first look at german Messerforum:

Vorstellung DMD Kombi-Diamantplatte 400/1200 mit Schliffbildern

Of course no one knows how long this plates last. But I took a 150/400 and 400/1000....

Just checked the low grit with a straight edge (Haarlineal). Its concave from end to end, definitely more than my Diaflat. Hhmmmm, .

I didn't ecpect that. And so far I can not tell how deep the concave is.

Attachments

I have the same plates in 400/1200. They are also sold as FOSS, and typically used for ice skate sharpening, due to their extra length.DMD diamond stones got some friends here around. Not much feedback, but cutting reliable with little wear.

Now DMD offers diamond plates. There is a first look at german Messerforum:

Vorstellung DMD Kombi-Diamantplatte 400/1200 mit Schliffbildern

Of course no one knows how long this plates last. But I took a 150/400 and 400/1000....

Just checked the low grit with a straight edge (Haarlineal). Its concave from end to end, definitely more than my Diaflat. Hhmmmm, .

I didn't ecpect that. And so far I can not tell how deep the concave is.

I have used mine by only using the loose plates (they are attached with magnets to the plastic) to shape convex stones.

I do not use them for stone flattening due to their flexibility, even when they are attached to the plastic holder they are not stiff enough.

Some good news, my 400/1000 is flat.

There are different builds. Mine are glued to aluminium profile.I have the same plates in 400/1200. They are also sold as FOSS, and typically used for ice skate sharpening, due to their extra length.

I have used mine by only using the loose plates (they are attached with magnets to the plastic) to shape convex stones.

I do not use them for stone flattening due to their flexibility, even when they are attached to the plastic holder they are not stiff enough.

On sluminium profile, glued? How much pressure do you use?My experience with this still dmd had the same problem. Gets worse with pressure.

I have used most all of the big-name diamond plates, own Atoma in 140, 400, 600 and 1200, and several of the no name Chinese eBay knock offs.

They all work, I have a Chinese trend knock off from Chef Knives to Go in 140 grit that has lapped hundreds of stones, chisel, and plane backs, must be 10+ years old and still going strong. The CNTG $30, 400/1k is also a work horse.

They all work, how long they last, is more about how they are used, I lap under running water to flush the swarf from between the diamonds. If you let the swarf build up it can rip out the diamonds. For lapping steel, I use a 50% Windex and water in a lab rinse squirt bottle.

I also clean my plates regularly, if one needs cleaning, I clean them all, about 8 that are in rotation, with a paste of Barkeepers, Oxalic Acid, let sit 10-15 minutes and scrub with a stiff fingernail brush, also keeps rust to minimum.

Dead flat? No, none of them, not a problem.

They all work, I have a Chinese trend knock off from Chef Knives to Go in 140 grit that has lapped hundreds of stones, chisel, and plane backs, must be 10+ years old and still going strong. The CNTG $30, 400/1k is also a work horse.

They all work, how long they last, is more about how they are used, I lap under running water to flush the swarf from between the diamonds. If you let the swarf build up it can rip out the diamonds. For lapping steel, I use a 50% Windex and water in a lab rinse squirt bottle.

I also clean my plates regularly, if one needs cleaning, I clean them all, about 8 that are in rotation, with a paste of Barkeepers, Oxalic Acid, let sit 10-15 minutes and scrub with a stiff fingernail brush, also keeps rust to minimum.

Dead flat? No, none of them, not a problem.

Depends on what i am doing. Not a ton. That aluminum flexes quit easily. Most objects are not as rigid as people think. There is a reason that a 9x12 surface plate is 2 inches thick.Some good news, my 400/1000 is flat.

There are different builds. Mine are glued to aluminium profile.

On sluminium profile, glued? How much pressure do you use?

- Thread starter

- #32

Ok, NOW we have some lapping real estate to work on.

Similar threads

- Replies

- 27

- Views

- 2K

- Replies

- 63

- Views

- 5K

- Replies

- 5

- Views

- 1K

- Replies

- 60

- Views

- 6K