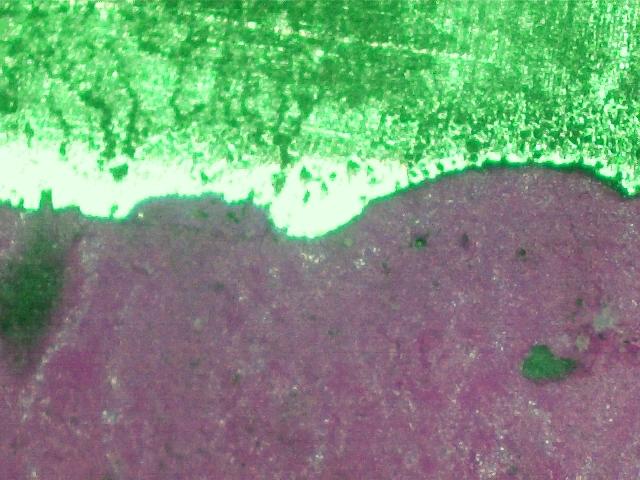

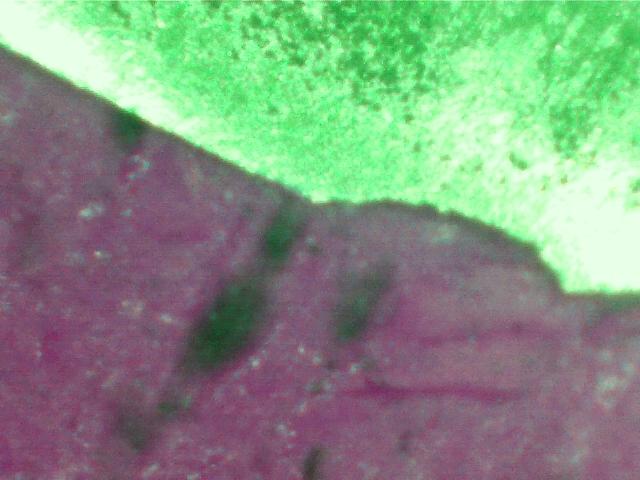

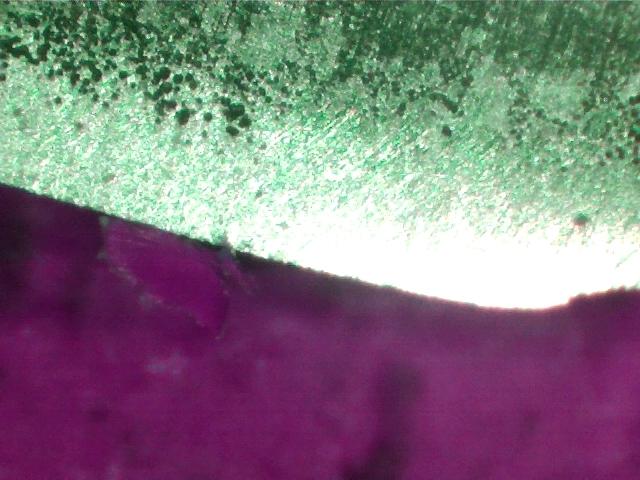

I think, for me, the magic is in their appearance.

They look nothing at all like what I had seen billed as a Frankonian.

Probably its the first time a real Frankonian ;-) because none of the stones before shown or sold were given a reference where they really had their origin....