We all know the business model of Gillette and other blade manufacturers ... the whole idea is to get us hooked on them to continue buying blades.

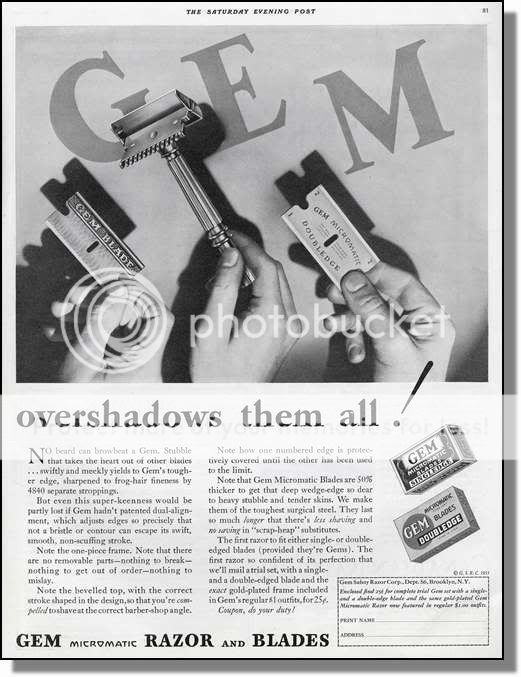

But ... why do they make a blade with 2 usable edges?

If they only made blades with ONE edge ...

a) Their manufacturing and overhead costs would be lower.

b) We'd have to buy blades twice as often.

So why was a DE blade introduced in the first place?

But ... why do they make a blade with 2 usable edges?

If they only made blades with ONE edge ...

a) Their manufacturing and overhead costs would be lower.

b) We'd have to buy blades twice as often.

So why was a DE blade introduced in the first place?