If that's the site I remember, the images are interesting, but they're used to draw conclusions that disregard way too many variables.

Basically, the guy doing it would bust the crap out of edges on DMT's... put gouges in them that would be visible to the naked eye then image them and declare that DMT's always do that (another forum's admin used to claim DMT's were unusable for razors... but totally not because they sold Nortons... his reasoning was that they chipped razors). I compared his shots to mine, even did scale adjustments, and what he was seeing simply didn't happen. I even tried DOZENS of other DMT's from coworkers and friends and not a single plate caused what he was seeing.

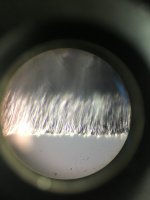

I WAS able to reproduce it by deliberately burring the edge and snapping it off (any experienced honer could do this easily if they wanted to prove a stone was bad... it'd be unlikely but not impossible for an inexperienced honer to do it inadvertently a time or two on a DMT, repeatedly doing would require intent) I actually took shots around 1k on optical magnification that mimicked his SEM shots relative to scale by doing this just to prove that it was not an issue of differences is our magnification, viewing angle, etc. Finally, I was able to reproduce it by using a razor that had lost it's tempering likely from an overzealous restorer on a buffer. Very similar pictures were taken of the "torn" edge that happens when you hone a razor that's lost temper. I concluded that either he was deliberately destroying the dmt edges for some reason unknown to me. OR He simply was a terrible honer, almost legendary in how bad he was (doubtful). OR he was imaging razors that weren't properly tempered or had lost temper.

Rereading his technique, he was burring and snapping the burrs. What he describes as his method is basically the "technique" required to do that on a EE DMT plate. Pressing a thin razor into an EE with "a few hundred grams" (think about a pound) of pressure (And likely far more as people tend to massively underestimate pressure used honing... if I asked you to press something down with 1lb of force, I'd guess you'll hit closer to 3lbs... and to that his claims that it was insensitive to swings in pressure... there's not much controllable range in pressure between 1lb and minimal that you could practically achieve what he claims by hand... again suggesting his estimate of a few hundred grams is very low) is of course going to result in exactly what he describes (flexing the edge away from the plate... thinning to a burr, and ripping the burr off). His entire test is based around a technique that is essentially designed to destroy an edge on an EE... so my guess is he wanted clicks at the revelation that a 325grit edge was better than an 8000 grit one. The 325 is fast enough to give appropriate results when he finishes @ the appropriate amount of pressure. The 8k, though fast, isn't going to be able to fix a bevel he probably tore 1/4-1/3 of off at the start of the test in the amount of time he was honing @ appropriate amounts of pressure. Pretty simple, really.

edit: testing my pressure to burr on my EE and actually 1 lb isn't enough to damage an edge on an EE. It takes almost exactly 3lbs to start to pull up a serious burr on a random hollow ground I grabbed. He must have massively underestimated the pressure use.

Basically, the guy doing it would bust the crap out of edges on DMT's... put gouges in them that would be visible to the naked eye then image them and declare that DMT's always do that (another forum's admin used to claim DMT's were unusable for razors... but totally not because they sold Nortons... his reasoning was that they chipped razors). I compared his shots to mine, even did scale adjustments, and what he was seeing simply didn't happen. I even tried DOZENS of other DMT's from coworkers and friends and not a single plate caused what he was seeing.

I WAS able to reproduce it by deliberately burring the edge and snapping it off (any experienced honer could do this easily if they wanted to prove a stone was bad... it'd be unlikely but not impossible for an inexperienced honer to do it inadvertently a time or two on a DMT, repeatedly doing would require intent) I actually took shots around 1k on optical magnification that mimicked his SEM shots relative to scale by doing this just to prove that it was not an issue of differences is our magnification, viewing angle, etc. Finally, I was able to reproduce it by using a razor that had lost it's tempering likely from an overzealous restorer on a buffer. Very similar pictures were taken of the "torn" edge that happens when you hone a razor that's lost temper. I concluded that either he was deliberately destroying the dmt edges for some reason unknown to me. OR He simply was a terrible honer, almost legendary in how bad he was (doubtful). OR he was imaging razors that weren't properly tempered or had lost temper.

Rereading his technique, he was burring and snapping the burrs. What he describes as his method is basically the "technique" required to do that on a EE DMT plate. Pressing a thin razor into an EE with "a few hundred grams" (think about a pound) of pressure (And likely far more as people tend to massively underestimate pressure used honing... if I asked you to press something down with 1lb of force, I'd guess you'll hit closer to 3lbs... and to that his claims that it was insensitive to swings in pressure... there's not much controllable range in pressure between 1lb and minimal that you could practically achieve what he claims by hand... again suggesting his estimate of a few hundred grams is very low) is of course going to result in exactly what he describes (flexing the edge away from the plate... thinning to a burr, and ripping the burr off). His entire test is based around a technique that is essentially designed to destroy an edge on an EE... so my guess is he wanted clicks at the revelation that a 325grit edge was better than an 8000 grit one. The 325 is fast enough to give appropriate results when he finishes @ the appropriate amount of pressure. The 8k, though fast, isn't going to be able to fix a bevel he probably tore 1/4-1/3 of off at the start of the test in the amount of time he was honing @ appropriate amounts of pressure. Pretty simple, really.

edit: testing my pressure to burr on my EE and actually 1 lb isn't enough to damage an edge on an EE. It takes almost exactly 3lbs to start to pull up a serious burr on a random hollow ground I grabbed. He must have massively underestimated the pressure use.

Last edited: