- Thread starter

- #41

Perfect. Have you thought about how you will cut the blade down?

Perfect. Have you thought about how you will cut the blade down?

I would round point it to save as much of the end of the blade as possible. You could do it by hand on some low grit sandpaper if you are unfamiliar with a dremel. That one could clean up quite well.

I am still waiting with mine, I am still looking for tools. and handle ideas.

I am still waiting with mine, I am still looking for tools. and handle ideas.I haven't decided yet whether I'll go square or round point. I like the look of a square point, but I could easily go either way.

I was considering this also... the length of the blade would be shorter if I went square. Ooh, I know... I'll do this one round and my next chipped resto will be square!

I borrowed my dad's Dremel yesterday... it's an older model (better than the current models!) and I still have a 220 piece kit from my Alltrade rotary tool that broke on it's 2nd or 3rd use. When I stop buying shaving treasures long enough to save up a little, I'm gonna get a Proxxon from Amazon. I'm also tempted to get a bench grinder from Harbor Freight... they have a sale on a 6" for $55 or an 8" for $75. For that cheap, who cares if it doesn't last as long?

I haven't decided yet whether I'll go square or round point. I like the look of a square point, but I could easily go either way.

I was considering this also... the length of the blade would be shorter if I went square. Ooh, I know... I'll do this one round and my next chipped resto will be square!

I borrowed my dad's Dremel yesterday... it's an older model (better than the current models!) and I still have a 220 piece kit from my Alltrade rotary tool that broke on it's 2nd or 3rd use. When I stop buying shaving treasures long enough to save up a little, I'm gonna get a Proxxon from Amazon. I'm also tempted to get a bench grinder from Harbor Freight... they have a sale on a 6" for $55 or an 8" for $75. For that cheap, who cares if it doesn't last as long?

If you have an Acme Tool in your area, the have a variable speed 8 inch bench grinder for $80. The 1750 speed is a great help for using it as a buffer, particularly with greaseless compound.

)

)OK, Go slow. Always keep the blade spine up in relation to the rotation of the stone. Keep a glass of water beside you and dip regularly to keep it cool. Wear eye protection. Have fun!

This has got to be the greatest thread ever! MORE PICS!!! Before and after!!!I am still waiting with mine, I am still looking for tools. and handle ideas.

I would just smooth out that pointy part to make it more round and go with that. Looks good so far

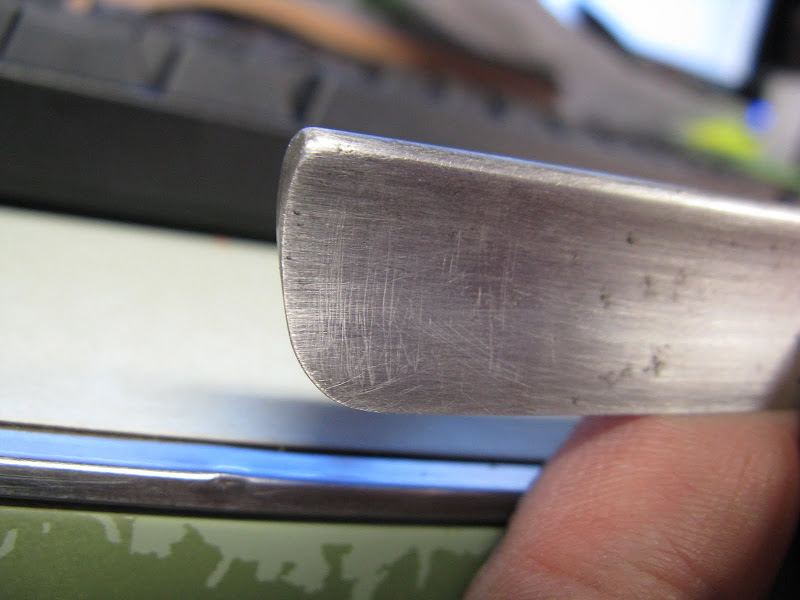

Good advice. I went back to the vice & dremel. Here's what I've got now.

You can see that I reshaped the point a bit while I was at it.

Those ugly vertical scratches are from me taking the dremel with a 120 grit sanding wheel to it before I realized that was dumb. I'm looking forward to sanding them out! Thanks for the advice... keep it coming if you have any more.

Now the big question the pitting is pretty deep, I`m sure I can sand it down and polish it up, as I work with metal in my day job. My concern is that this is thinner than anything I have worked on, it looks like at least a couple .0001" on each side`, is this going to make the blade too fragile?

Not sure if I can finish one up in the amount of time that's left might not be doable for me (finals and national boards coming up quick) but I have many blades I got for under $10 that I have needed some motivation on restoring, this just might be it! I love watching threads like this...

I was just planning on keeping this as an ongoing thing, so anybody who wants to, jump in anytime!Well, maybe we should have a $10 restoration challenge each month! Then I can adopt a new AD... Junk Straight Acquisition Disorder!