Hello Gents,

I just wanted to post up a quick how wo, on how I make my scales. I am no proffesional by any means, and while this is probably not the correct way to make em, it works for me Excuse the pics, I used my iphone and just kinda snapped pics along the way. the whole process took me no more than an hour and half. Any and all comments welcome!! thanks guys, enjoy!

Excuse the pics, I used my iphone and just kinda snapped pics along the way. the whole process took me no more than an hour and half. Any and all comments welcome!! thanks guys, enjoy!

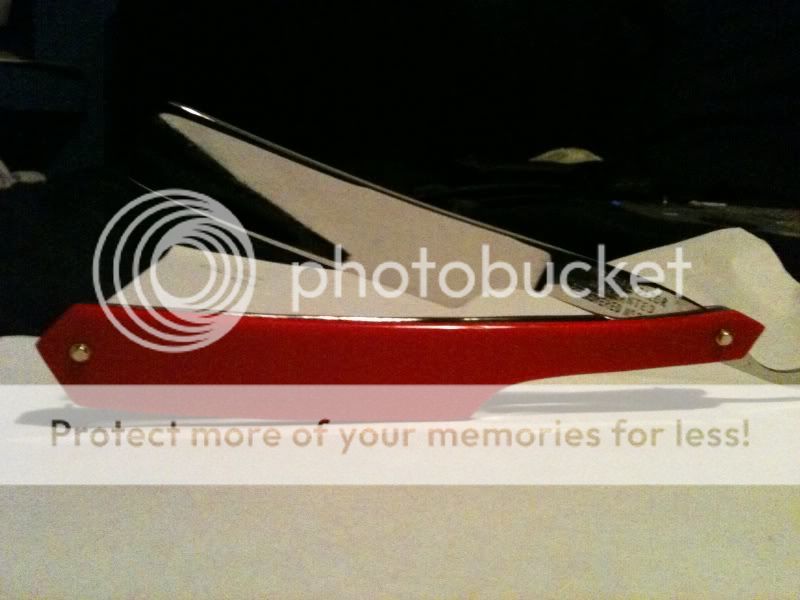

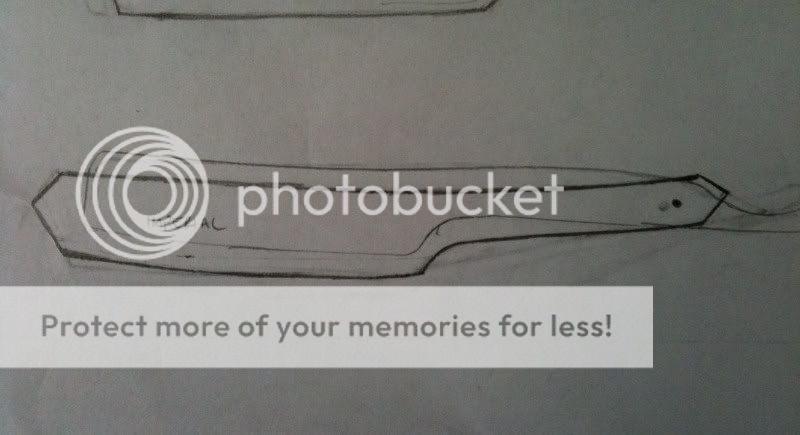

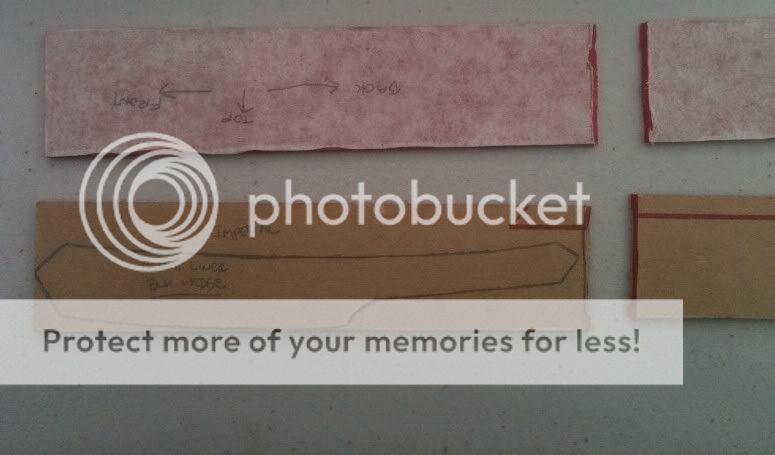

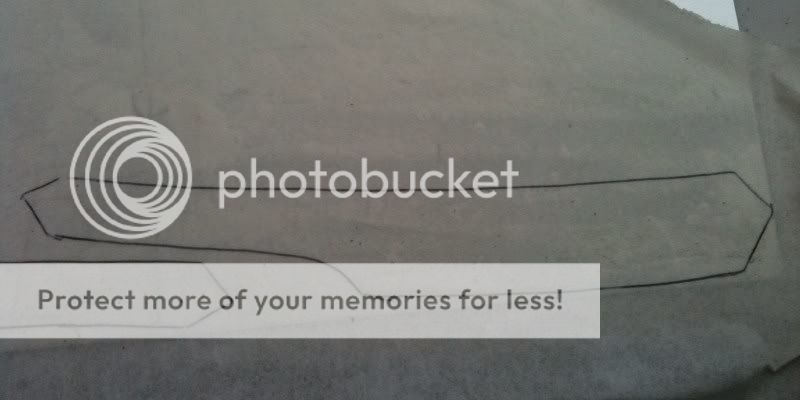

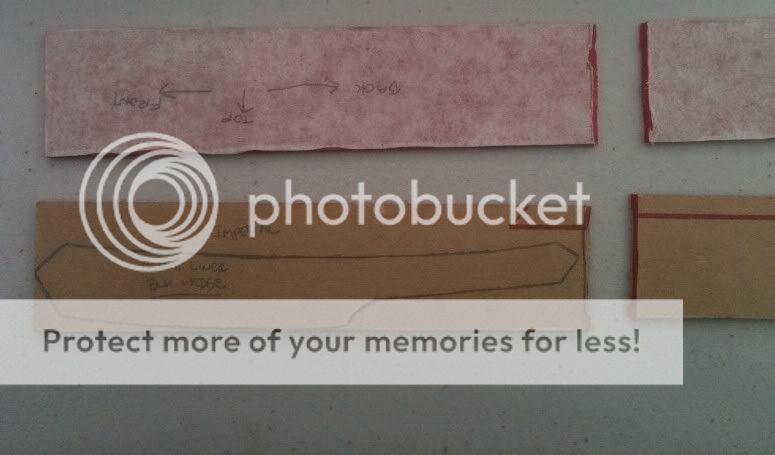

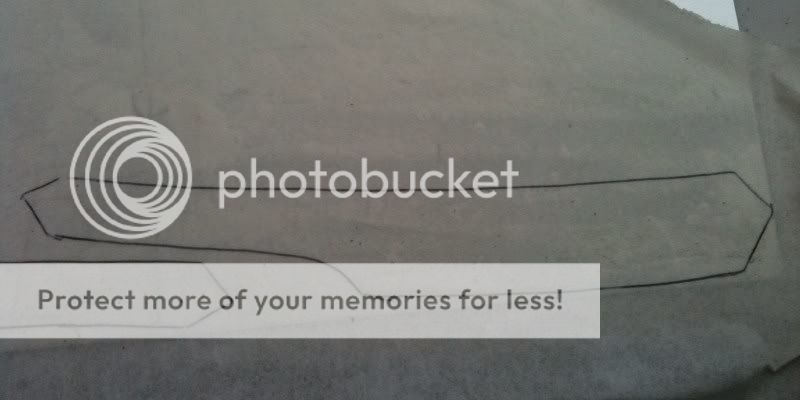

1. I draw my design

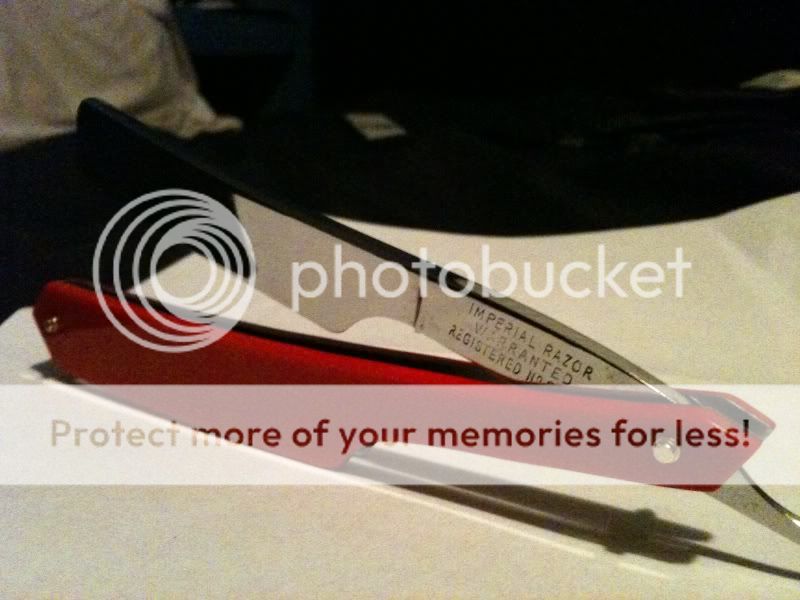

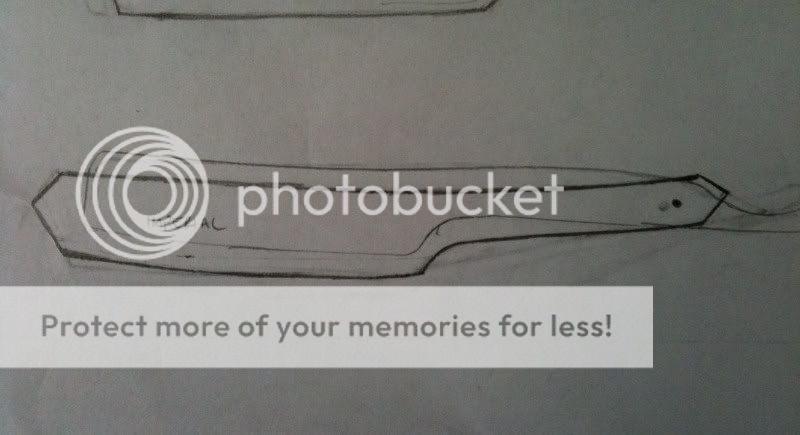

2. Cut out design and try it out on the blade to make sure I like it.

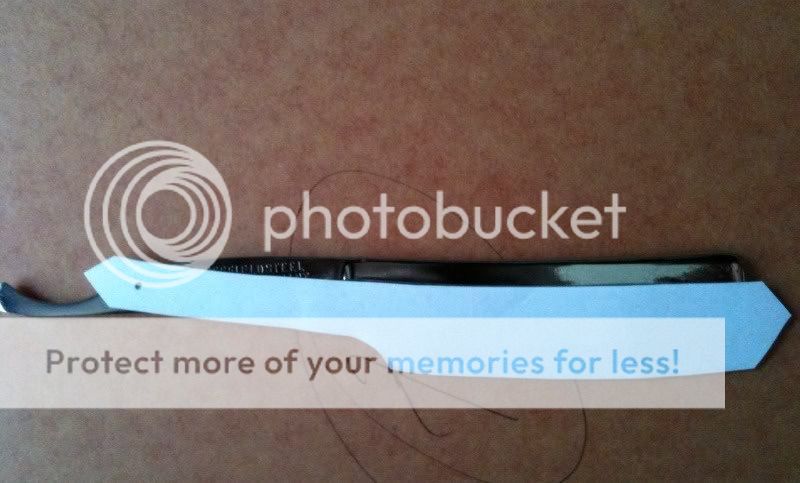

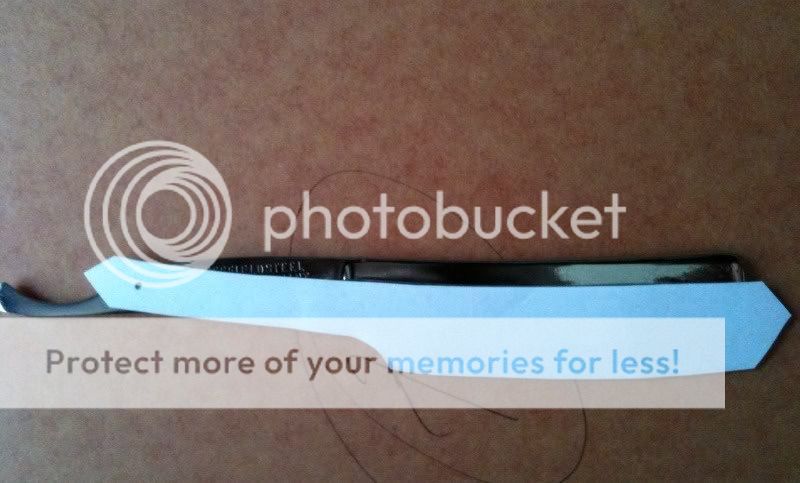

3. Transfer to Acrylic

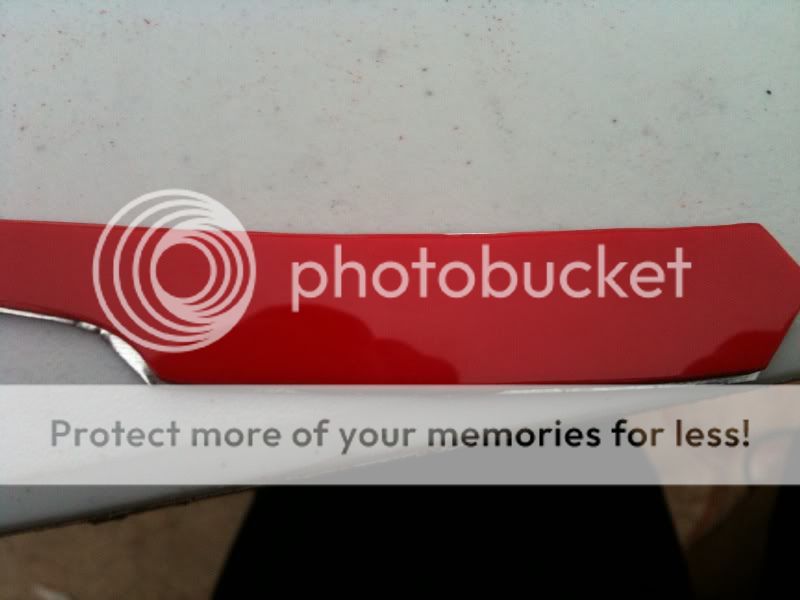

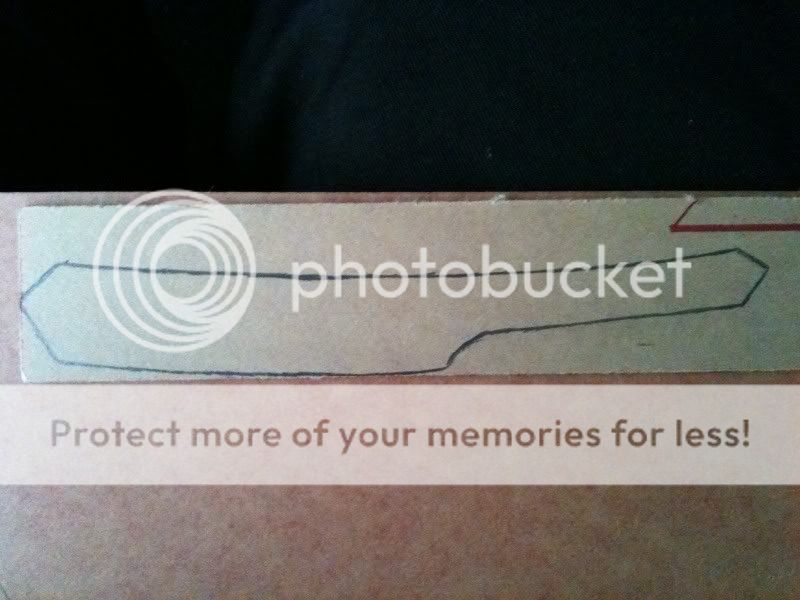

4. Trim Acrylic down a bit, and save the scrap pieces for future wedges.

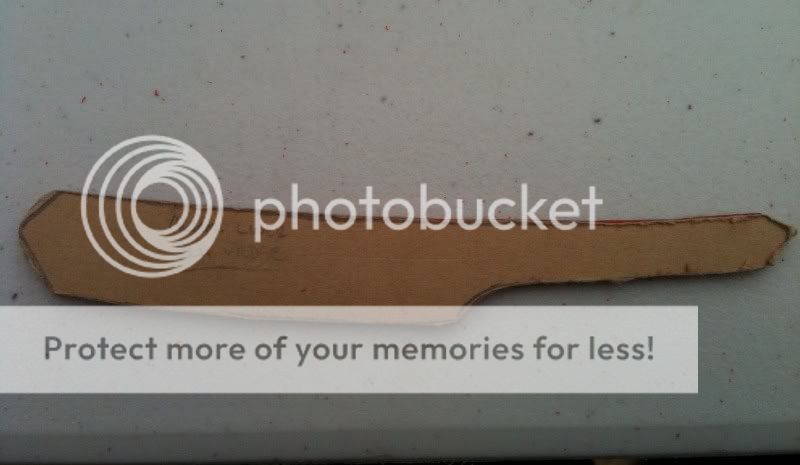

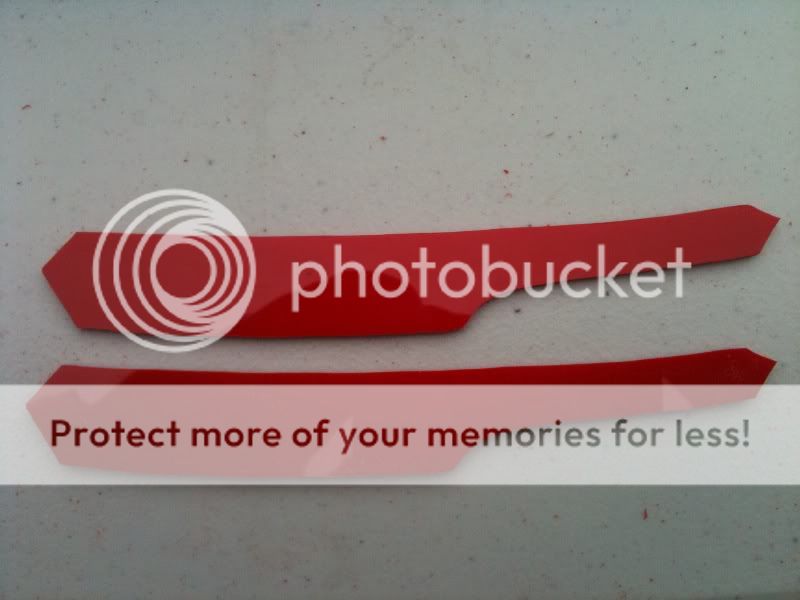

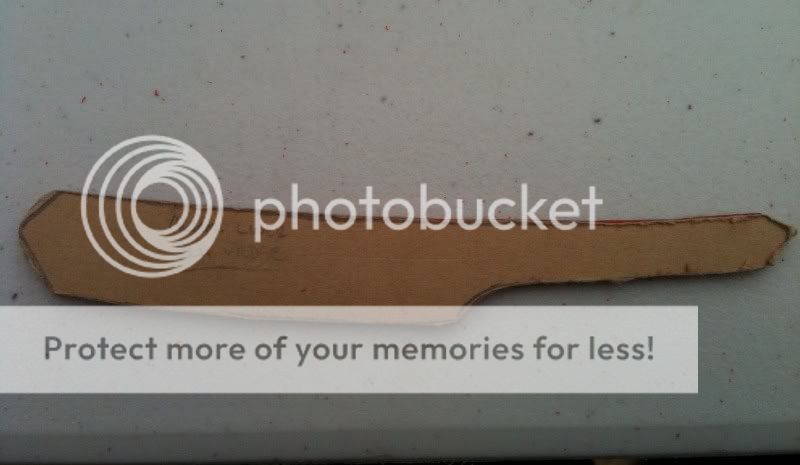

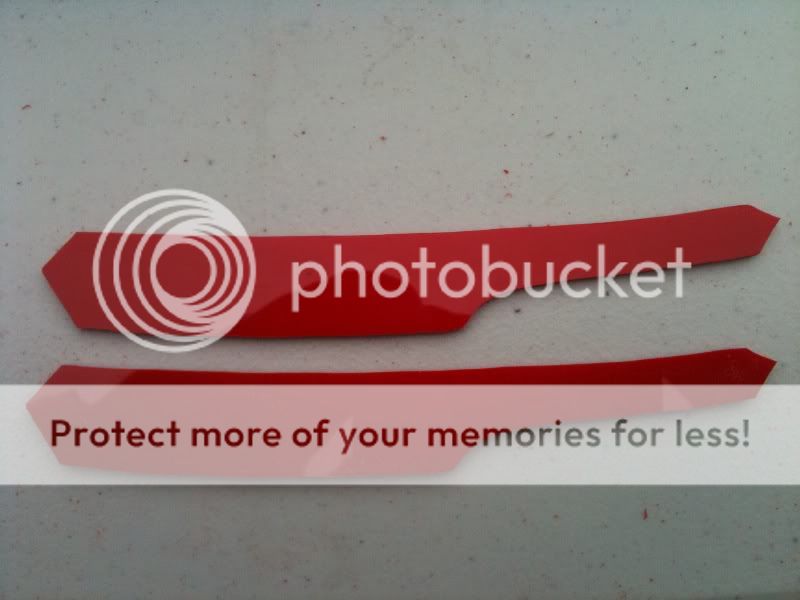

5. Using the Dremel with a cutting wheel, I cut around the the line, dont cut right on the line because you need to cut the other scale out and you need a little bit of room to sand them together down the line so that they are the same size.

6. Using a 1/2in sanding drum, sand both scales together down to the lines to get them equal.

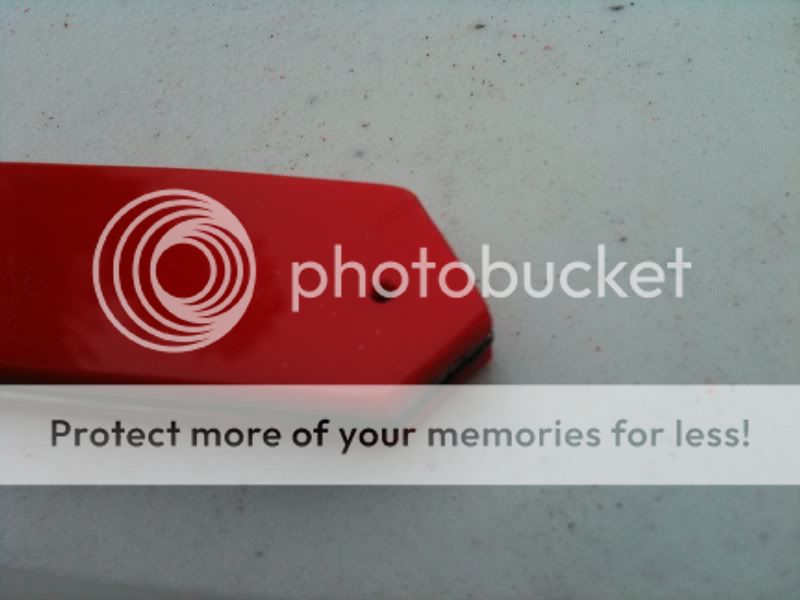

7. Here are both of em, pretty close to being the same.

8. Tape both scales together, and use the blade to mark the pin location for the tang. Drill it with a 1/16 drill bit. I also use this step to mark out my wedge.

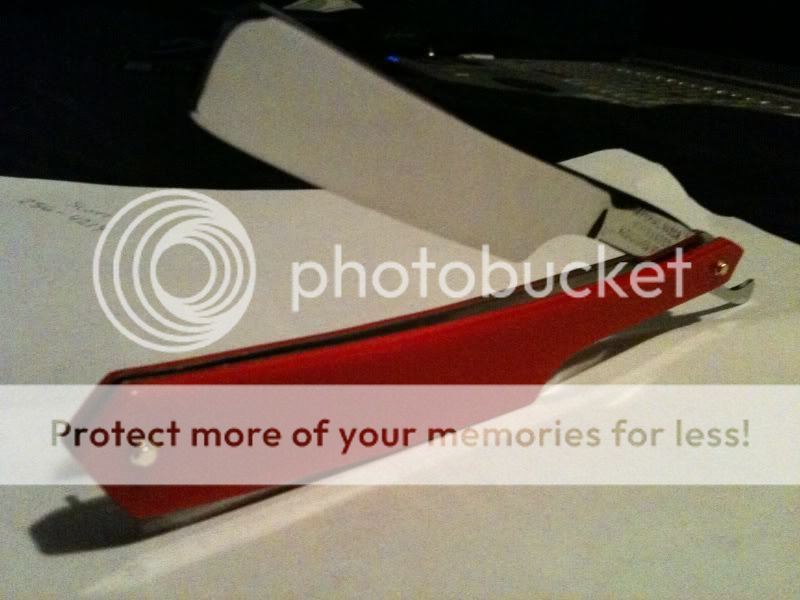

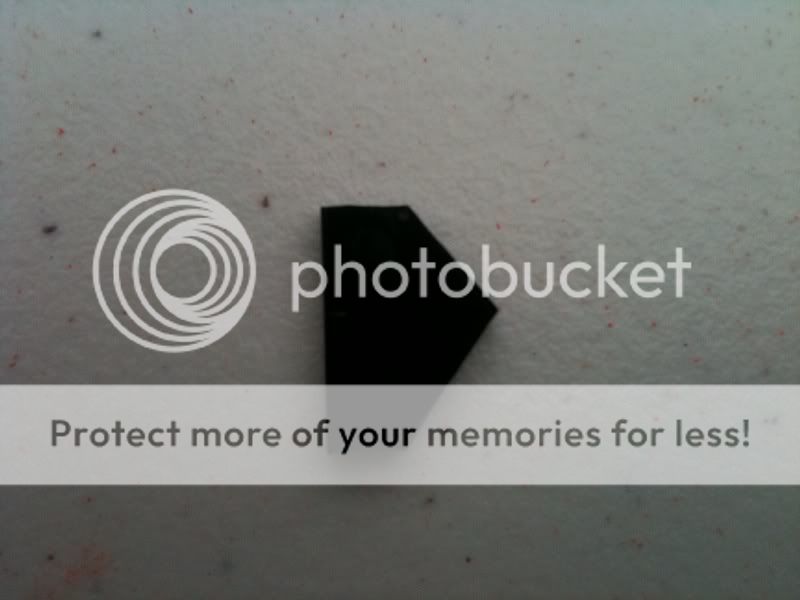

9. Here is the wedge after a rough cut.

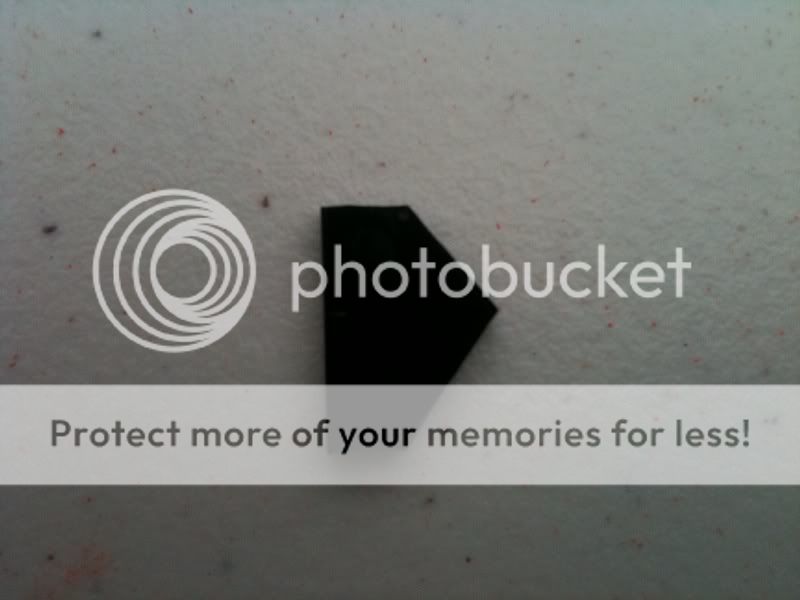

10. This time I whent ahead and tried to make a liner, I have never done this before so forgive my noobness. lol. I traced the design onto a small .008 piece of aluminum. I have .016 and .032, but I thought id try it with this first.

11. Here is the liner after a quik trim with some tin snips.

I just wanted to post up a quick how wo, on how I make my scales. I am no proffesional by any means, and while this is probably not the correct way to make em, it works for me

Excuse the pics, I used my iphone and just kinda snapped pics along the way. the whole process took me no more than an hour and half. Any and all comments welcome!! thanks guys, enjoy!

Excuse the pics, I used my iphone and just kinda snapped pics along the way. the whole process took me no more than an hour and half. Any and all comments welcome!! thanks guys, enjoy!1. I draw my design

2. Cut out design and try it out on the blade to make sure I like it.

3. Transfer to Acrylic

4. Trim Acrylic down a bit, and save the scrap pieces for future wedges.

5. Using the Dremel with a cutting wheel, I cut around the the line, dont cut right on the line because you need to cut the other scale out and you need a little bit of room to sand them together down the line so that they are the same size.

6. Using a 1/2in sanding drum, sand both scales together down to the lines to get them equal.

7. Here are both of em, pretty close to being the same.

8. Tape both scales together, and use the blade to mark the pin location for the tang. Drill it with a 1/16 drill bit. I also use this step to mark out my wedge.

9. Here is the wedge after a rough cut.

10. This time I whent ahead and tried to make a liner, I have never done this before so forgive my noobness. lol. I traced the design onto a small .008 piece of aluminum. I have .016 and .032, but I thought id try it with this first.

11. Here is the liner after a quik trim with some tin snips.

12. I superglued the aluminum onto the scales.

12. I superglued the aluminum onto the scales.