You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I got famous! LOL

- Thread starter sbogill

- Start date

I'd be curious to see the other side of this convo. He seems... agitated.

I don't have an opinion convex vs flat. Both work fine.

PSDO almost universally arrive convex (200+ yr old stones)... I flatten them and see zero difference in performance before vs after.

I suspect the functional difference is more along the lines of a small scale micro-beveling process. Speeds up honing for guys who are struggling to do enough work otherwise... and as such some guys see great results... and others see nothing.

I always question people's opinions when it's become a business for them. I don't ask my propane dealer what the best heating fuel is.

If I'm reading his opinion correctly; he's essentially arguing for replacing the microbevel from pasted stropping that was a contentious topic 15 years ago here (again that some people loved/needed, but others found useless or a negative) with a microbevel from a convexed honing surface. Each produces a subtle, continuous (rather than discontinuous) microbevel. Functionally the resulting edge should be similar in that respect.

Not every tool is perfect for everyone*; doesn't need to be a fight.

*Except Thuringians

I don't have an opinion convex vs flat. Both work fine.

PSDO almost universally arrive convex (200+ yr old stones)... I flatten them and see zero difference in performance before vs after.

I suspect the functional difference is more along the lines of a small scale micro-beveling process. Speeds up honing for guys who are struggling to do enough work otherwise... and as such some guys see great results... and others see nothing.

I always question people's opinions when it's become a business for them. I don't ask my propane dealer what the best heating fuel is.

If I'm reading his opinion correctly; he's essentially arguing for replacing the microbevel from pasted stropping that was a contentious topic 15 years ago here (again that some people loved/needed, but others found useless or a negative) with a microbevel from a convexed honing surface. Each produces a subtle, continuous (rather than discontinuous) microbevel. Functionally the resulting edge should be similar in that respect.

Not every tool is perfect for everyone*; doesn't need to be a fight.

*Except Thuringians

- Thread starter

- #3

Here is the video I was replying to if you want to see it. I don’t care that he hones that way. What bothers me is that he says his way is the right way and normal honing is wrong. My comment should be at the top—the most recent one.

Here it is

Here it is

I skimmed it. He clearly put a lot of work into it...

My experience with convex hones is that his theory (as I gather from skimming) that they in fact concave the bevel doesn't seem to play out in reality. As I mentioned; they rather seem to convex the bevel; as the stage in honing where the edge is riding the higher point on the hone generates far more edge pressure and abrasion than the second half of the stone face where the spine would be riding higher on the stone.

I know he's done a ton of work on these hones and tools to convex hones/etc... maybe he's found a solution to that... but my very limited experience says that you essentially microbevel on the front half of your honing strokes and then polish the bevel on the second half with a convex hone.

But these are secondary effects. The primary effect is to reduce contact area of the bevel and spine with the hone and significantly increase the pressure applied.

To concave the bevel as he suggests; I would expect you would need to hone on the very center of a convex surface and move the razor perpendicular to the surface... which does not create a good razor edge. Or hone on a true wheel, not a convex, stationary surface.

IE if you REALLY want the concave bevel the video seems to promote... you should be using a buffing wheel and ultra-fine abrasive to finish... and even that's more likely to convex unless you set it up absolutely perfect and have a very near solid wheel. That's really the only practical way I can think of doing it. We don't because it's generally not desirable in razors... other tools are a different story. I mean when we're talking about convexing a chisel; you're probably talking about a sweet spot of several mm to properly position it on the wheel. With a razor it'd be more like a sweet spot of a few micrometers. And the give (flex) in most buffing wheels would render it impossible. ... Plus the likelyhood of cooking a razor if you aren't paying close attention.

My experience with convex hones is that his theory (as I gather from skimming) that they in fact concave the bevel doesn't seem to play out in reality. As I mentioned; they rather seem to convex the bevel; as the stage in honing where the edge is riding the higher point on the hone generates far more edge pressure and abrasion than the second half of the stone face where the spine would be riding higher on the stone.

I know he's done a ton of work on these hones and tools to convex hones/etc... maybe he's found a solution to that... but my very limited experience says that you essentially microbevel on the front half of your honing strokes and then polish the bevel on the second half with a convex hone.

But these are secondary effects. The primary effect is to reduce contact area of the bevel and spine with the hone and significantly increase the pressure applied.

To concave the bevel as he suggests; I would expect you would need to hone on the very center of a convex surface and move the razor perpendicular to the surface... which does not create a good razor edge. Or hone on a true wheel, not a convex, stationary surface.

IE if you REALLY want the concave bevel the video seems to promote... you should be using a buffing wheel and ultra-fine abrasive to finish... and even that's more likely to convex unless you set it up absolutely perfect and have a very near solid wheel. That's really the only practical way I can think of doing it. We don't because it's generally not desirable in razors... other tools are a different story. I mean when we're talking about convexing a chisel; you're probably talking about a sweet spot of several mm to properly position it on the wheel. With a razor it'd be more like a sweet spot of a few micrometers. And the give (flex) in most buffing wheels would render it impossible. ... Plus the likelyhood of cooking a razor if you aren't paying close attention.

Last edited:

None of this is true.I skimmed it. He clearly put a lot of work into it...

My experience with convex hones is that his theory (as I gather from skimming) that they in fact concave the bevel doesn't seem to play out in reality. As I mentioned; they rather seem to convex the bevel; as the stage in honing where the edge is riding the higher point on the hone generates far more edge pressure and abrasion than the second half of the stone face where the spine would be riding higher on the stone.

I know he's done a ton of work on these hones and tools to convex hones/etc... maybe he's found a solution to that... but my very limited experience says that you essentially microbevel on the front half of your honing strokes and then polish the bevel on the second half with a convex hone.

But these are secondary effects. The primary effect is to reduce contact area of the bevel and spine with the hone and significantly increase the pressure applied.

To concave the bevel as he suggests; I would expect you would need to hone on the very center of a convex surface and move the razor perpendicular to the surface... which does not create a good razor edge. Or hone on a true wheel, not a convex, stationary surface.

IE if you REALLY want the concave bevel the video seems to promote... you should be using a buffing wheel and ultra-fine abrasive to finish... and even that's more likely to convex unless you set it up absolutely perfect and have a very near solid wheel. That's really the only practical way I can think of doing it. We don't because it's generally not desirable in razors... other tools are a different story. I mean when we're talking about convexing a chisel; you're probably talking about a sweet spot of several mm to properly position it on the wheel. With a razor it'd be more like a sweet spot of a few micrometers. And the give in most buffing wheels would render it impossible.

I fixed that for you.Your personal opinion is not true in my personal opinion

We don't want "bullying" here now do we?

Last edited:

I mean geometry is pretty important. Assuming an x pattern on a convex hone, the razor is going to be held at the angle formed at center; which is going to be the highest angle at any point along the edge. Assume the same pressure and pattern you would use on a flat hone; the increase in force applied could be calculated out with the ratios of surface area in contact; forces down and forward and the angle the hone takes at the points of contact.

It's not the most easy math, but it's pretty obvious once you get into it that the force... especially the force at the edge is going to increase quite a lot.

Some experience honing translates that to two effects; recessing the edge and increasing edge angle over use... otherwise known as microbeveling.

Now translate that to the effect once you get over the hump so to speak. You essentially have a razor ground at (original angle) + (angle formed on the first half of your hone... so rise over run -on the hone- for your razor's depth)... and you're on a hone that is cut to hone a razor of (original angle) - (angle formed on the first half of your hone).

The effect of that? Edge off the hone, polishing the bevel.

Throw in the complication of an X stroke and the full length of the blade not being on the hone at a given time... so the toe likely isn't seeing this reforming because it may not even be in contact until you pass the middle of the hone... and it can get quite complicated... but that's where the fact that this is such a minute impact comes into play and the significant impact of the aforementioned pressure increase at the points of contact becomes the overwhelming impact of having a hone surfaced like this.

So again, if you REALLY want to dig into the mechanics and geometry of a honing surface that's slightly uneven... it can be solved. But in practice; the overwhelming effect is essentially the same as using a very narrow hone or honing on the edge of a hone... isolating a small area of the edge while honing.

But no, expecting an x pattern with a razor on a stationary, convex hone to concave the bevel just doesn't make sense.

It's not the most easy math, but it's pretty obvious once you get into it that the force... especially the force at the edge is going to increase quite a lot.

Some experience honing translates that to two effects; recessing the edge and increasing edge angle over use... otherwise known as microbeveling.

Now translate that to the effect once you get over the hump so to speak. You essentially have a razor ground at (original angle) + (angle formed on the first half of your hone... so rise over run -on the hone- for your razor's depth)... and you're on a hone that is cut to hone a razor of (original angle) - (angle formed on the first half of your hone).

The effect of that? Edge off the hone, polishing the bevel.

Throw in the complication of an X stroke and the full length of the blade not being on the hone at a given time... so the toe likely isn't seeing this reforming because it may not even be in contact until you pass the middle of the hone... and it can get quite complicated... but that's where the fact that this is such a minute impact comes into play and the significant impact of the aforementioned pressure increase at the points of contact becomes the overwhelming impact of having a hone surfaced like this.

So again, if you REALLY want to dig into the mechanics and geometry of a honing surface that's slightly uneven... it can be solved. But in practice; the overwhelming effect is essentially the same as using a very narrow hone or honing on the edge of a hone... isolating a small area of the edge while honing.

But no, expecting an x pattern with a razor on a stationary, convex hone to concave the bevel just doesn't make sense.

Last edited:

The force does not change. The only thing that changes is the normal surface pressure. Normal pressure =force/area.It's not the most easy math, but it's pretty obvious once you get into it that the force... especially the force at the edge is going to increase quite a lot.

You are in control of the force.

The reason you don't dig into the stone is because you are cutting the bevel from the back. As you start to reach the apex you need to use a hard stone to avoid rounding the apex. If you use as soft stone for this final step you are wasting your time, and it's true what you said, you will be rounding the apex.

A wheel does not have a high spot, or a start and finish.Now translate that to the effect once you get over the hump so to speak. You essentially have a razor ground at (original angle) + (angle formed on the first half of your hone... so rise over run for your razor depth)... and you're on a hone that is cut to hone a razor of (original angle) - (angle formed on the first half of your hone).

Last edited:

Convex stones are an interesting topic. I just wish the foremost advocate of them, quoted in the OP, didn't have such a severe personality disorder. It seems to taint every conversation on the subject, and has so far kept me away from trying such stones.

I agree. In my opinion, part of the problem is that the advantages of using these stones have been oversold. I asked Gary (a barber in the UK) if he was still using his convex stones. He was not, but added that the razors he honed with the convexed stones cut a little better when you got them just right.Convex stones are an interesting topic. I just wish the foremost advocate of them, quoted in the OP, didn't have such a severe personality disorder. It seems to taint every conversation on the subject, and has so far kept me away from trying such stones.

Getting them just right takes allot of effort, and might not be worth it for most people, in my opinion.

I also think that there is a post hoc fallacy in the causal reasoning when success stories are used as a proof of concept.

Even if people report better results after using convex stones, it does not prove anything. Failure to succeed using flat stones does not mean they inferior to convex stones.

It just means you failed to learn how to use their full potential.

Last edited:

The force per unit area increases, which yes would be pressure. I agree, referring to it as force (because that is the element you think of from a honing perspective), rather than what it technically is may be confusing.The force does not change. The only thing that changes is the normal surface pressure. Normal pressure =force/area.

You are in control of the force.

The reason you don't dig into the stone is because you are cutting the bevel from the back. As you start to reach the apex you need to use a hard stone to avoid rounding the apex. If you use as soft stone for this final step you are wasting your time, and it's true what you said, you will be rounding the apex.

A wheel does not have a high spot, or a start and finish.

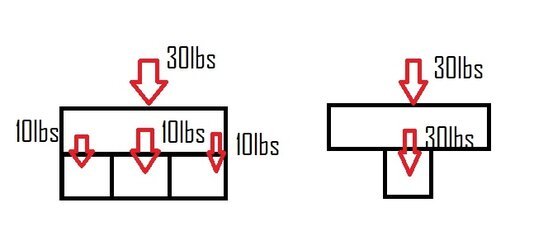

My point was that at a given segment of the edge (whether you want to select a 1micronx1micron section or a 10mm long strip of the bevel), the force that is acting on that area will go up and consequently... the amount of material removed from the bevel/edge there will typically increase also.

Simple paint image to demonstrate why I referred to it as more "force" rather than more "pressure", because only the point of contact in the use of the convex hone was being considered. So while the force being applied to the razor is unchanged (actually assuming this)... the force at a given area in contact with the convex hone is greater than an equivalent area would experience from contact with a flat hone.

And a wheel (or sphere) segment that has been bisected by a plane absolutely has a high point. And a curve across the surface of that object absolutely has a start and a finish.

Attachments

Last edited:

Yes, and as you said can be a problem, especially if soft stones are used.The force per unit area increases, which yes would be pressure. I agree, referring to it as force (because that is the element you think of from a honing perspective), rather than what it technically is may be confusing.

My point was that at a given segment of the edge (whether you want to select a 1micronx1micron section or a 10mm long strip of the bevel), the force that is being transmitted by the pressure at that area will go up and consequently... the amount of material removed from the bevel/edge there will typically increase also.

And a wheel bisected by a plane absolutely has a high point. And a curve across the surface of that object absolutely has a start and a finish.

Allot of things needs to lign up to get this to work.

Yeah, definitely can be useful or problematic. That's not a discussion I want to dig into. The effect is pretty well understood by most honers I would think and they can decide how they want their stones surfaced and make it so.

My main point was that this idea that a convex hone will concave a razor bevel isn't logical. Now that may not be the point of the video... as I said I just skimmed it... but there was a lot of talking about how great concave bevels are on chisels... so I assumed that was the end-point was that convex hones can be used to create that effect on razor bevels... which I don't understand how that would be possible in any practical way.

My main point was that this idea that a convex hone will concave a razor bevel isn't logical. Now that may not be the point of the video... as I said I just skimmed it... but there was a lot of talking about how great concave bevels are on chisels... so I assumed that was the end-point was that convex hones can be used to create that effect on razor bevels... which I don't understand how that would be possible in any practical way.

Not to wade too far into the weeds, I think I would simply ignore the response the OP got. There is absolutely no point in arguing with someone who refuses to listen or who gets nasty when questioned.

My actual contribution will the be following -- if a stone is convex on a fairly large radius (that is, not visible to the eye) there will be very minimal concaving of the bevel, it's not very wide unless on a near wedge with lots of wear. Concavity isn't really desireable in a razor edge anyway, it reduces strength behind the edge. I suspect this is why many commercial blades are sharpened to "gothic arch" edges instead of flat bevels -- convexity adds strength while only very slightly reducing the sharpness of the actual cutting edge.

Double convex stones, used with the same hand pressure as a flat stone, will indeed have higher pressure at the contact area since it will be rather small. Size depends on the radius of the convexity, but any sphereocity will reduce the length of the contact no matter what you do with the razor. A single axis convex stone would have full edge contact only if the blade is perpendicular to axis of the convexity, anything off perpendicular will leave parts of the edge out of contact.

I don't see any real differences in result from the two approaches, as long as you have a clean apex and a decently polished bevel it's gonna shave just fine.

My actual contribution will the be following -- if a stone is convex on a fairly large radius (that is, not visible to the eye) there will be very minimal concaving of the bevel, it's not very wide unless on a near wedge with lots of wear. Concavity isn't really desireable in a razor edge anyway, it reduces strength behind the edge. I suspect this is why many commercial blades are sharpened to "gothic arch" edges instead of flat bevels -- convexity adds strength while only very slightly reducing the sharpness of the actual cutting edge.

Double convex stones, used with the same hand pressure as a flat stone, will indeed have higher pressure at the contact area since it will be rather small. Size depends on the radius of the convexity, but any sphereocity will reduce the length of the contact no matter what you do with the razor. A single axis convex stone would have full edge contact only if the blade is perpendicular to axis of the convexity, anything off perpendicular will leave parts of the edge out of contact.

I don't see any real differences in result from the two approaches, as long as you have a clean apex and a decently polished bevel it's gonna shave just fine.

That is perfectly understandable.which I don't understand how that would be possible in any practical way.

If a human hair is 100 micron, at 50 micron you will be at the peak of the cutting resistance.

If someone is claiming they can affect the first 50 micron in a meaningful way by using a convex stone they are fooling them self, in my opinion.

The abrasive size, hardness and pressure over that given abrasive is more important for the actual apex width you end up with.

However, you can change the bevel flexibility quite allot, and change the way it shaves.

I ended up getting name dropped on his website at one point over some forum posts. He doesn’t seem like a very happy individual.

You actually need to use several stones with different shapes to get any meaningful results in my opinion.My actual contribution will the be following -- if a stone is convex on a fairly large radius (that is, not visible to the eye) there will be very minimal concaving of the bevel,

My first stone would be a 1-2 m wheel, followed by two more steps with larger wheels.

If the first step is taken too far you will probably end up with edge failure.

If you spend too much time on the following steps you also risk undoing the work you did at the first step.

So, it's not a paint by numbers situation.

There might be a reward at the end, but as Gary said, you need to get it just right.

I don’t know why we keep giving free advertising to this guy.

lots of ways to skin a cat. Sharpest razor I ever used was honed on a 5K and stropped on paste to a mirror finished bevel by a guy in France. I couldn’t do it but some can. Same with convex hones, flat hones, films etc. Do what works for you.

Using a convexed hone might theoretically make the edge of a razor marginally concaved, if you could hone perfectly. But the edge of a razor is so thin that this effect will be unnoticeable, even if you could.

The thing that a convex hone would do more than anything else is: reduce the angle of the edge (bevel). Because with a single, perfect and even, stroke on a razor that has previously been honed on a flat stone - you will abrade the shoulders of the edge more than the edge itself. Because the shoulders are thicker than the edge.

Hence, after a while, you end up with an edge angle that is more acute than the same razor honed on a completely flat stone. And thinner things are sharper.

It’s like taking a knife and sharpening it at a lower angle than it’s been sharpened at before, to create a new, more acute, edge. It’s quite easy to change it on a knife because you sharpen the edge with the bevel and spine lifted off the stone.

You don’t sharpen a razor like that. And so the spine gets in the way of trying to reduce the edge angle. You can grind away the spine a bit, or you can use a convex hone.

That’s basically what’s happening. The idea of concaving the edge of a razor is irrelevant - it’s too small. Convex razor stones is an angle reduction thing.

The thing that a convex hone would do more than anything else is: reduce the angle of the edge (bevel). Because with a single, perfect and even, stroke on a razor that has previously been honed on a flat stone - you will abrade the shoulders of the edge more than the edge itself. Because the shoulders are thicker than the edge.

Hence, after a while, you end up with an edge angle that is more acute than the same razor honed on a completely flat stone. And thinner things are sharper.

It’s like taking a knife and sharpening it at a lower angle than it’s been sharpened at before, to create a new, more acute, edge. It’s quite easy to change it on a knife because you sharpen the edge with the bevel and spine lifted off the stone.

You don’t sharpen a razor like that. And so the spine gets in the way of trying to reduce the edge angle. You can grind away the spine a bit, or you can use a convex hone.

That’s basically what’s happening. The idea of concaving the edge of a razor is irrelevant - it’s too small. Convex razor stones is an angle reduction thing.

Last edited:

Similar threads

- Replies

- 8

- Views

- 2K

- Replies

- 3

- Views

- 2K

- Replies

- 5

- Views

- 962