I got this Joseph Fenton & Sons a while ago but it's been in my "to do" pile for ages.

I took it out the other day and started restoring it but couldn't figure out what the scales are made from.

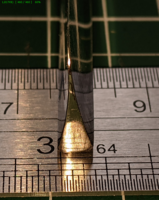

Before I did anything with it it appeared to be a hard pressed leather. Felt like it, looked like it. See picture.

Then I took it apart and started sanding it and my thoughts moved to wood, I thought maybe ebony.

When sanding the scales the paper got coated in a very dark brown mud like substance, so again I wasn't sure.

I thought maybe it's celluloid but I've never worked with it before so I wouldn't be sure. I usually only work with horn or wood.

(I guestimate the razor to be 130+ years old but if anyone knows different let me know. Age might help eliminate some materials)

I have the razor sanded to a level I can live with and the scales are clean and matte looking. Usually, with the process I use on scales, they would be shiny (up to 12k grit) but it seems they want to stay matte black (or an extremely dark brown) so I'm not going to argue with them.

I was about to peen the wedge in when the scales started to stick to the steel block I use (there's a magnet attached) and I thought is that wedge not lead?

I took the wedge back out and put it to the magnet and it didn't stick. I took the Nickel silver rod I was using and held it to the magnet and that didn't stick.

I was thinking, what the hell, and when I picked up the scale it was lightly stuck to the magnet .

.

What the hell is this scale made out of, I've never come across this material before.

I took it out the other day and started restoring it but couldn't figure out what the scales are made from.

Before I did anything with it it appeared to be a hard pressed leather. Felt like it, looked like it. See picture.

Then I took it apart and started sanding it and my thoughts moved to wood, I thought maybe ebony.

When sanding the scales the paper got coated in a very dark brown mud like substance, so again I wasn't sure.

I thought maybe it's celluloid but I've never worked with it before so I wouldn't be sure. I usually only work with horn or wood.

(I guestimate the razor to be 130+ years old but if anyone knows different let me know. Age might help eliminate some materials)

I have the razor sanded to a level I can live with and the scales are clean and matte looking. Usually, with the process I use on scales, they would be shiny (up to 12k grit) but it seems they want to stay matte black (or an extremely dark brown) so I'm not going to argue with them.

I was about to peen the wedge in when the scales started to stick to the steel block I use (there's a magnet attached) and I thought is that wedge not lead?

I took the wedge back out and put it to the magnet and it didn't stick. I took the Nickel silver rod I was using and held it to the magnet and that didn't stick.

I was thinking, what the hell, and when I picked up the scale it was lightly stuck to the magnet

.

.What the hell is this scale made out of, I've never come across this material before.