The idea of sanding razor blades to a mirror shine does not appeal to me. Too much like hard work

I bought a pack of felt wheels for the dremel and started polishing with the pastes I had left over (5 - 1 micron).

Results were amazing. Very shiny mirror finish with not a lot of effort.

If you plan on doing enough polishing to make it worth it, think about a bench setup and a large cotton buffing wheel. I use my bench grinder and a 6" wheel and it works very quickly. With care it does a very good job.

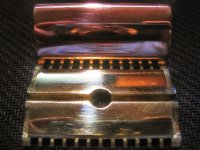

My Gillette NEW SC base and cap as I got them.

After a quick sand with 600 grit wet paper and on my wheel for less than 5 minutes with white rouge.

If I had a slower speed motor and used progressively finer rouges there would be more depth to the shine. Heat is your enemy.

I kind of suspected cutting acrylic and kirinite would be done slow due to it's tendency to melt.

Theres a trick when working with acrylic...

You can polish and even round the edges with a bit of acetone on a rag. It takes some time but the finished result is fantastic. If you want to speed it up, 600>1200>2000 grit wet paper and finish with acetone. Acetone will give acrylic an ultra smooth finish. It works because acetone melts plastics, just very slowly.

I'll look into the router Mike. Have a feeling it may be the wrong thing to use with Acrylic or Kirinite because of it's tendancy to melt if you don't take it easy. Plus Acrylic is brittle.

I could be totaly wrong about that of course.

Low speed = less heat. Less pressure = less heat. The same effect can be seen polishing steel on too high a speed too aggressively. Heat is your enemy.

.

.