I have seen tiny glue dots on couple of blade in 2s or 4s but I haven't seen any blade have two blobs as big as on Feathers.

Them dots have been part of manufacturing process for long time and didn't really bothered our grandpa's and their sons. I don't wish to represent here the emasculated matrosexual male these times are trying to make us, but why the heck Feathers just keep on doing those annoyingly big blobs? Is Feathers a part of some DuPont safety program cartel wanting us to live in a safety peranoia?

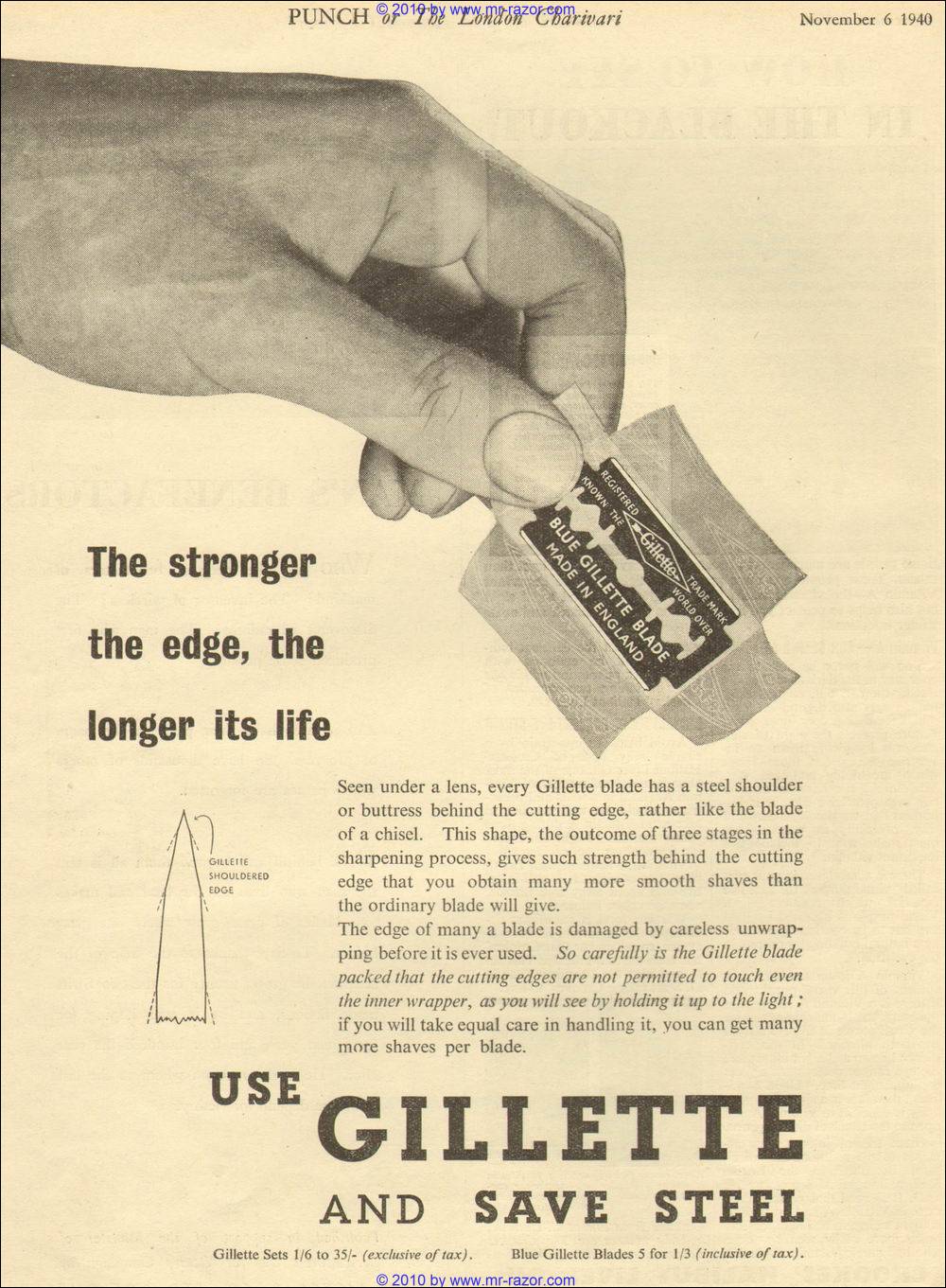

If you didn't or forgot to plan beforehand then very act of wanting to change a new blade during shave is fraught with dangers. While removing the blade from screw top plate, blade is stuck underneath pretty solid. Even if you are able to shake the blade loose and down the head stem, you still have to grapple with wrapper of still packed blade. The blade is firmly attached and glued to the wrapper and your are pushing your luck for some disaster to happen.

I don't want to think it is big deal but how do you stay safe other than planning before? That sticky thing doesn't wash away even in hot water.

Them dots have been part of manufacturing process for long time and didn't really bothered our grandpa's and their sons. I don't wish to represent here the emasculated matrosexual male these times are trying to make us, but why the heck Feathers just keep on doing those annoyingly big blobs? Is Feathers a part of some DuPont safety program cartel wanting us to live in a safety peranoia?

If you didn't or forgot to plan beforehand then very act of wanting to change a new blade during shave is fraught with dangers. While removing the blade from screw top plate, blade is stuck underneath pretty solid. Even if you are able to shake the blade loose and down the head stem, you still have to grapple with wrapper of still packed blade. The blade is firmly attached and glued to the wrapper and your are pushing your luck for some disaster to happen.

I don't want to think it is big deal but how do you stay safe other than planning before? That sticky thing doesn't wash away even in hot water.