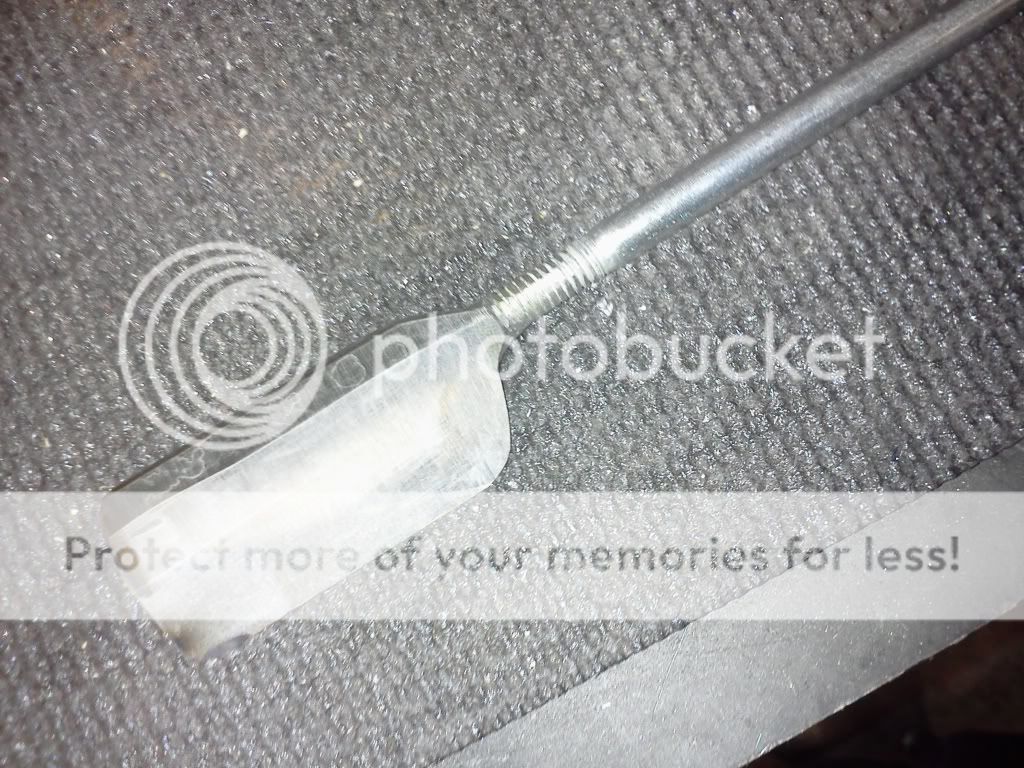

First is made of O1 steel, 6/8 with a 2" cutting edge.

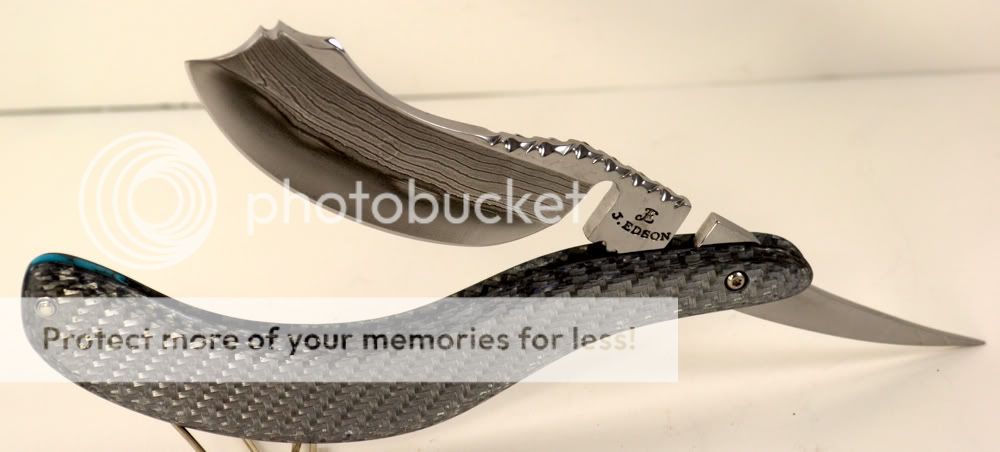

The next is made of ATS 34 stainless steel. 8/8 with a 1 3/4" cutting edge.

Man what a pain to grind. The honing wasn't terrible but grinding to to shape was a beast..lol

I'll be trying a different SS before I bust out another piece of this..lol

The next is made of ATS 34 stainless steel. 8/8 with a 1 3/4" cutting edge.

Man what a pain to grind. The honing wasn't terrible but grinding to to shape was a beast..lol

I'll be trying a different SS before I bust out another piece of this..lol

Let me also add that you did a great job and it looks fantastic! Very Nice Indeed!

Let me also add that you did a great job and it looks fantastic! Very Nice Indeed!