As you start to shop for vintage safety razors you'll notice that, in addition to the many Gillette double edge and Gem/Star/Ever-Ready single edge models, there is a third group of razors known as "injector" razors. From time to time people post questions about how they work, how to determine if they're good and how to fix them if they're not good. We have a pretty accepted set of terms for DE razor anatomy but most of us aren't comfortable discussing the parts of an injector razor, never mind how they function.

Recently one of our more experienced DE collectors who goes by the user name poonjaji contacted me with a concern about a gold handled G type razor that he'd received that had a very loose head. He observed that the spring rivet was loose and I suggested how he could re-set the rivet using a bearing ball and a vice-grips tool. Much to my surprise, he ultimately just sent me the razor. I decided that I should document this particular razor fix so that people would feel a little less queasy about approaching these razors.

First, there's a good reference for identifying the various models of "Schick" injector razors. It can be found here. If anyone knows of other on-line references, I'll gladly add them to this posting.

To the casual observer, the Schick razors of the mid 30's to mid 40's and the Eversharp Shicks of the mid 40's to mid 50's all look to be the same design. For the sake of this article we'll treat them as more or less the same. I have, so far, only owned G type razors, so that's what you will see in the illustrations. Most of what you see here should apply also to the E type and even the very rare D and F types.

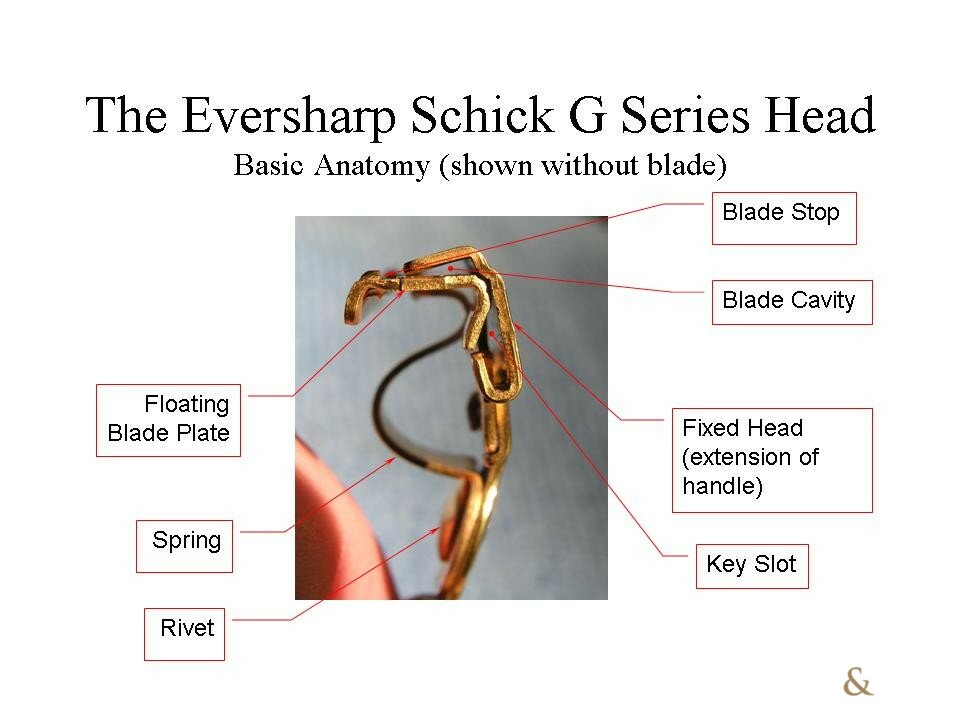

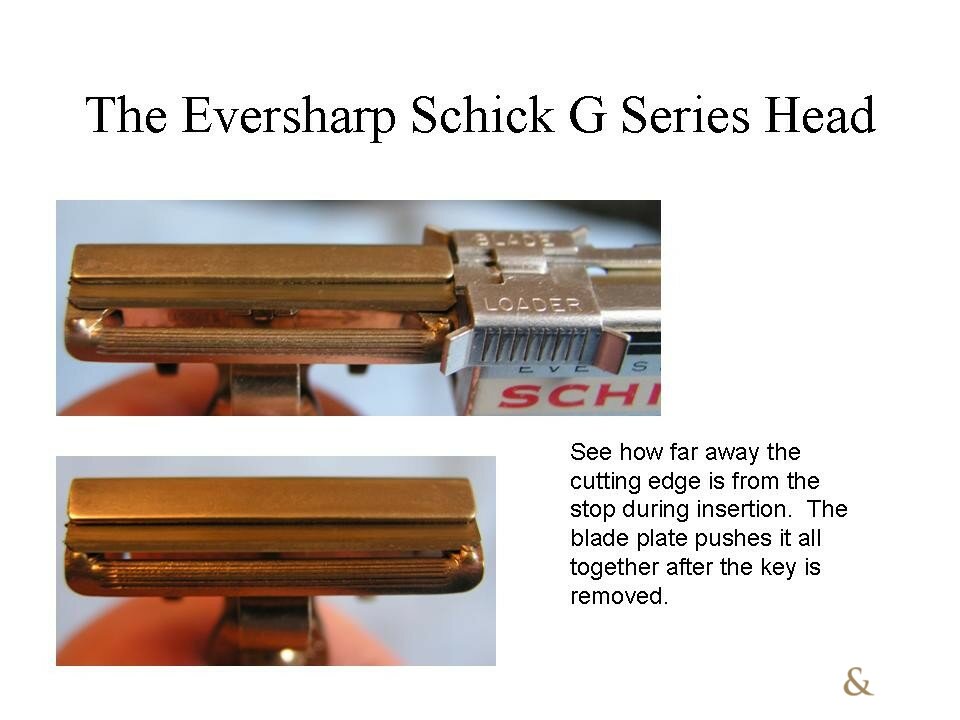

Here's a view of the underside of a G type head:

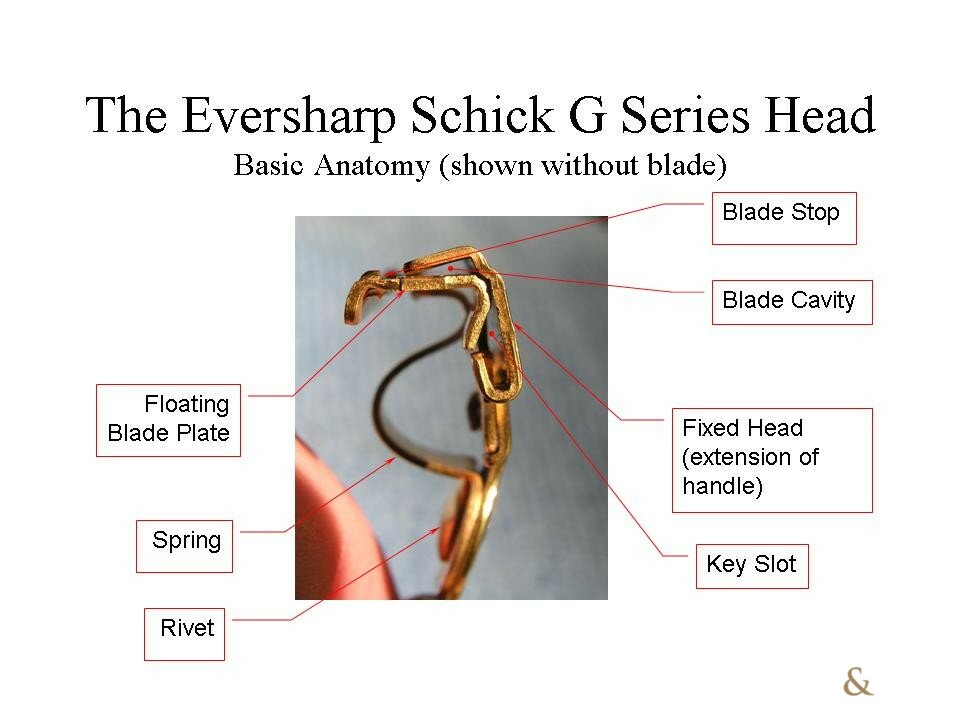

It has one "floating" part, which I've named the floating blade plate. I pulled that name out of the air. I'm open to other part names. The blade plate is held in place by a large curved spring (the big blur in the center of the figure). The early versions of the E model razor head readily allow this spring to pivot ~110° counterclockwise for removing the blade plate. The later models (including all of the G types) have the spring retained in such a way that it has to be seriously deformed before it can be pivoted. I'm convinced that many springs get damaged as people attempt to open these razors up and I strongly recommend against that practice.

Here's a side view of the head:

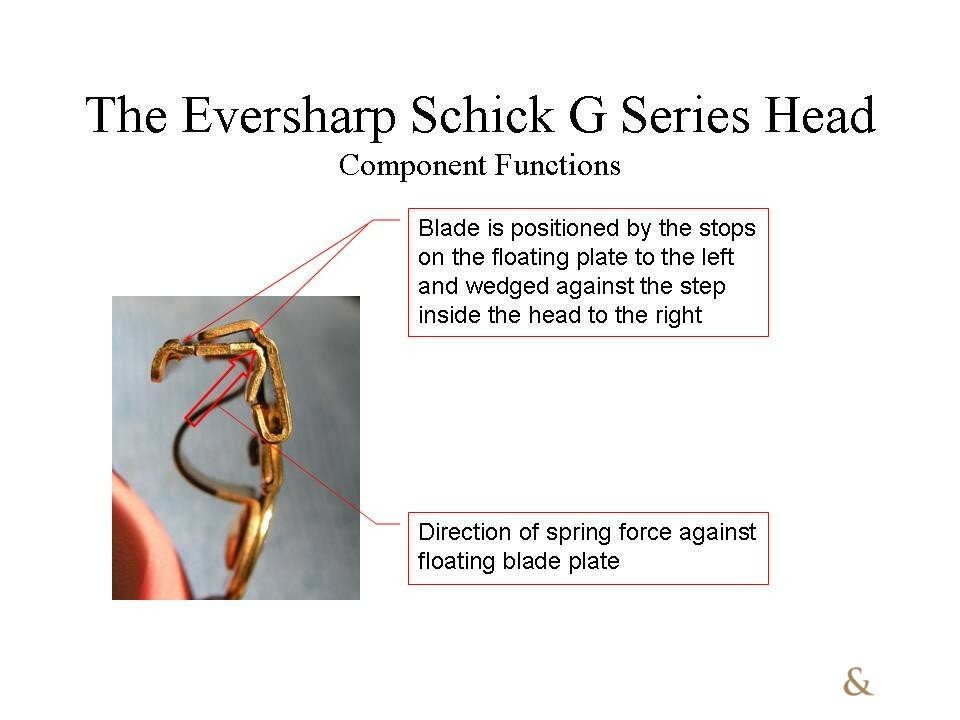

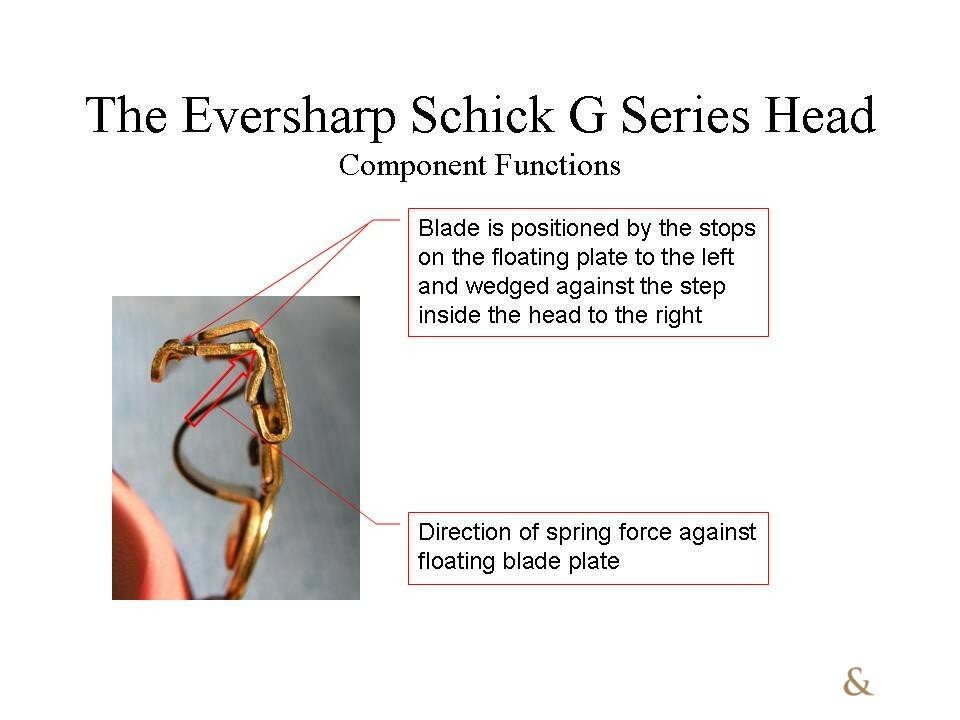

The beauty of the injector head design is that it allows replacement of the blade without actually handling the blade itself. As with an SE razor, the blade cutting edge is positioned by direct contact with two small protruding stops, one at each end of the safety bar. The spring plays a very important rôle here. It forces the blade forward against the stops (or the stops backward against the blade) and at the same time clamps the blade tightly to avoid blade chatter.

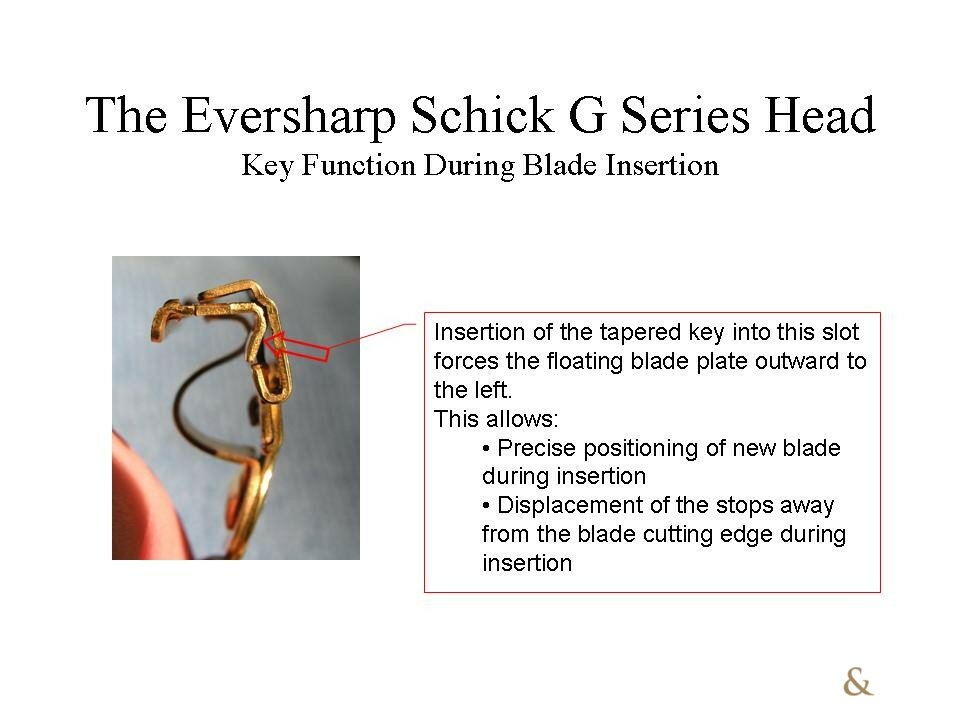

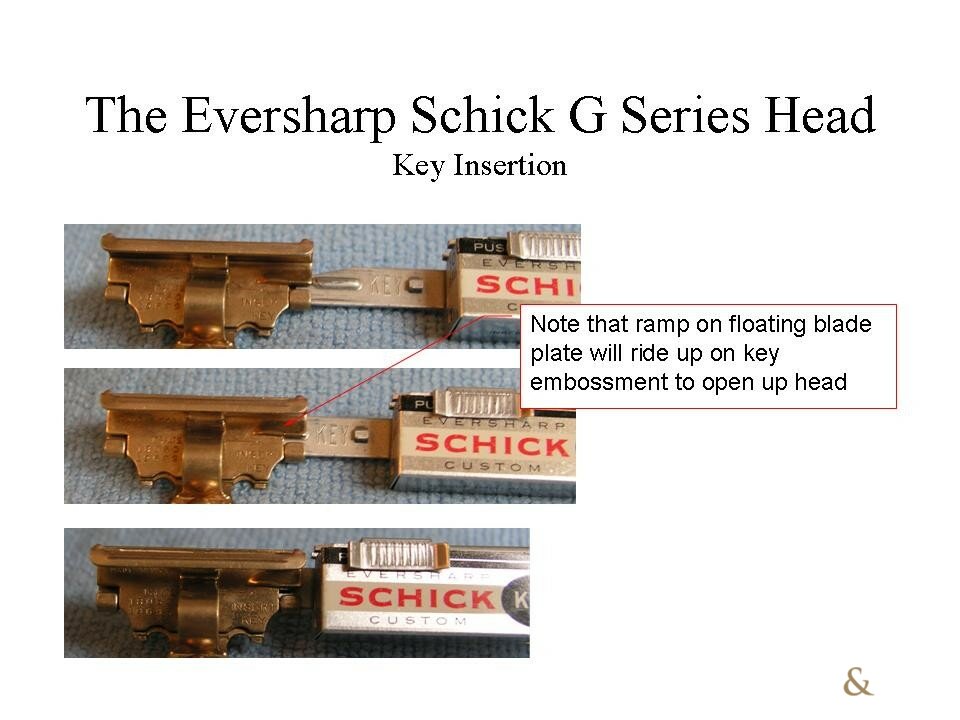

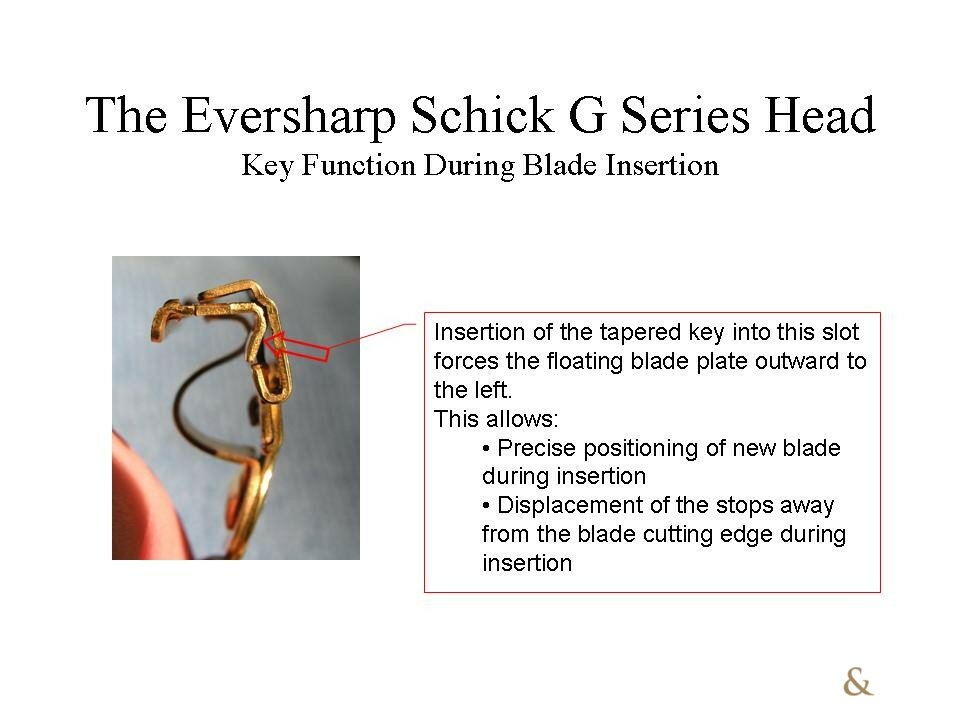

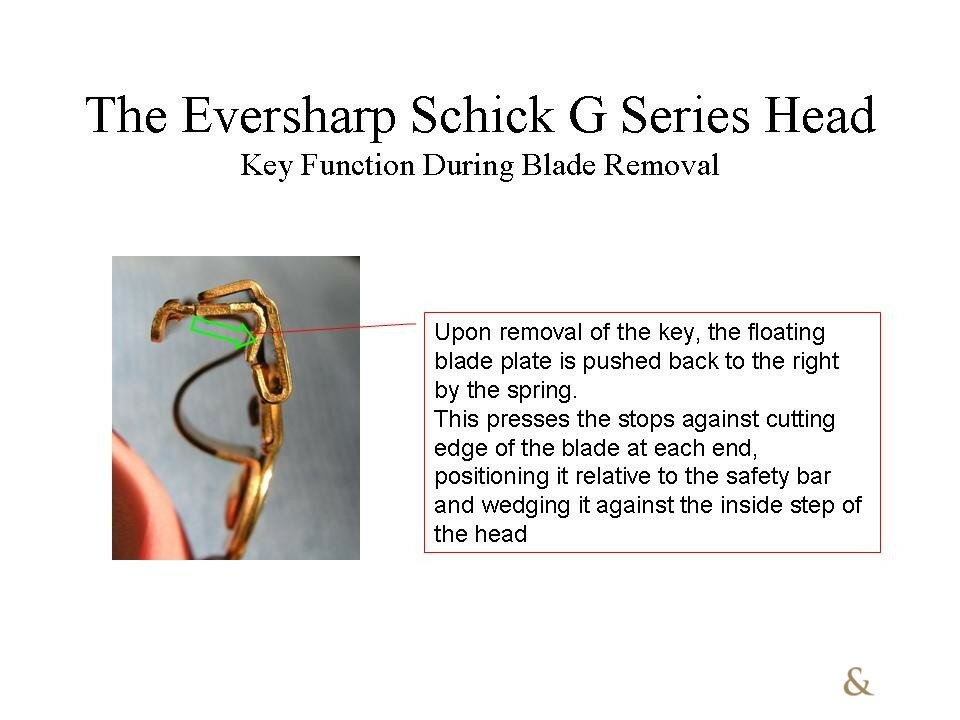

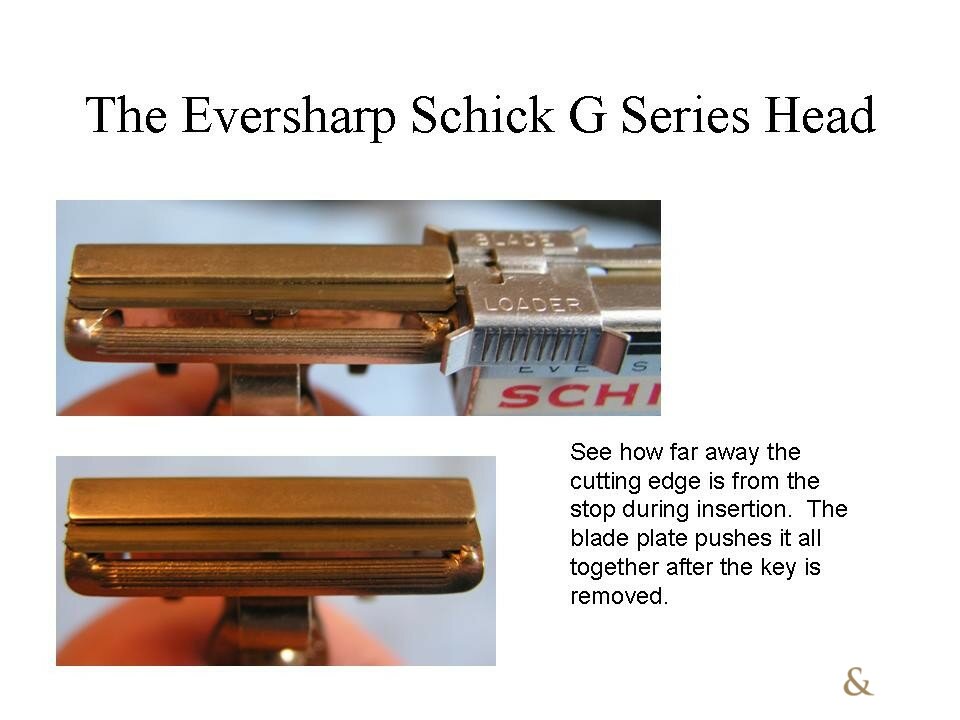

Since the blade is inserted from the side of the razor (pushing the old blade out ahead of it) there's a risk of drawing the new blade's edge across the nearside stop during its insertion, effectively ruining it. In order to avoid that, the injector cartridge key and key slot are designed to force the floating blade plate outward (to the left in the illustrations) while the new blade is inserted up and away from the stop.

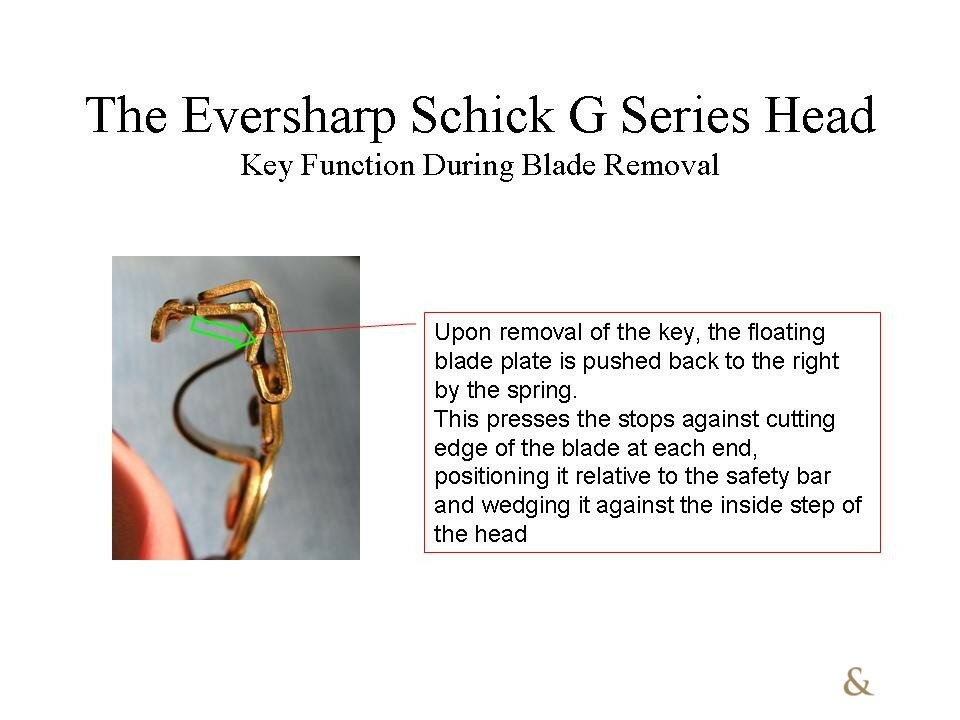

After the cartridge key is removed, the spring forces the blade plate to the right, seating the stops against the new blade edge and rigidly clamping it in place.

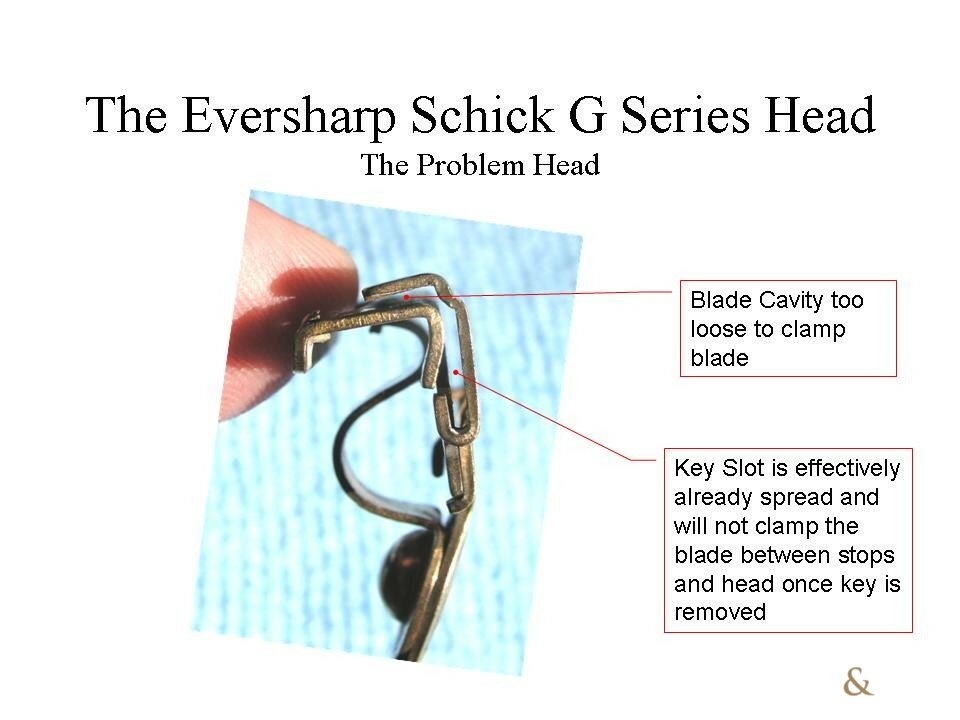

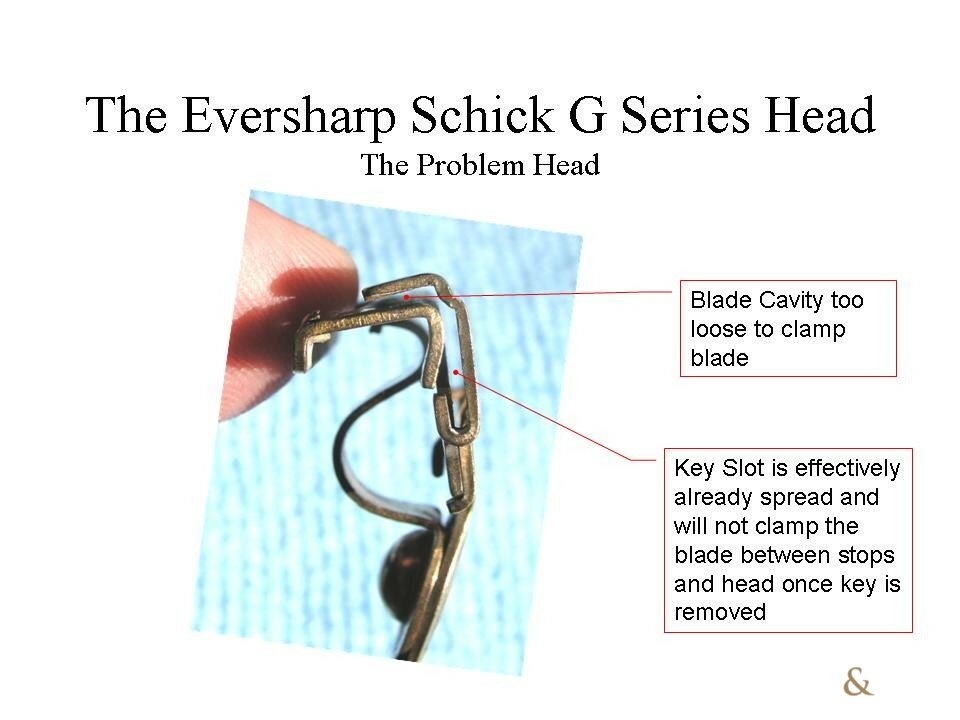

The "problem" razor's head that I mentioned earlier was very loose. As you can see, the blade plate was already floating. The risk of using such a razor primarily is that the blade will "chatter". This really means that it will bite you. It may also means that the blade won't automatically seat against the stops. Practically speaking though, once you've pressed against the safety bar the blade plate floats into its appropriate position anyway.

It may also means that the blade won't automatically seat against the stops. Practically speaking though, once you've pressed against the safety bar the blade plate floats into its appropriate position anyway.

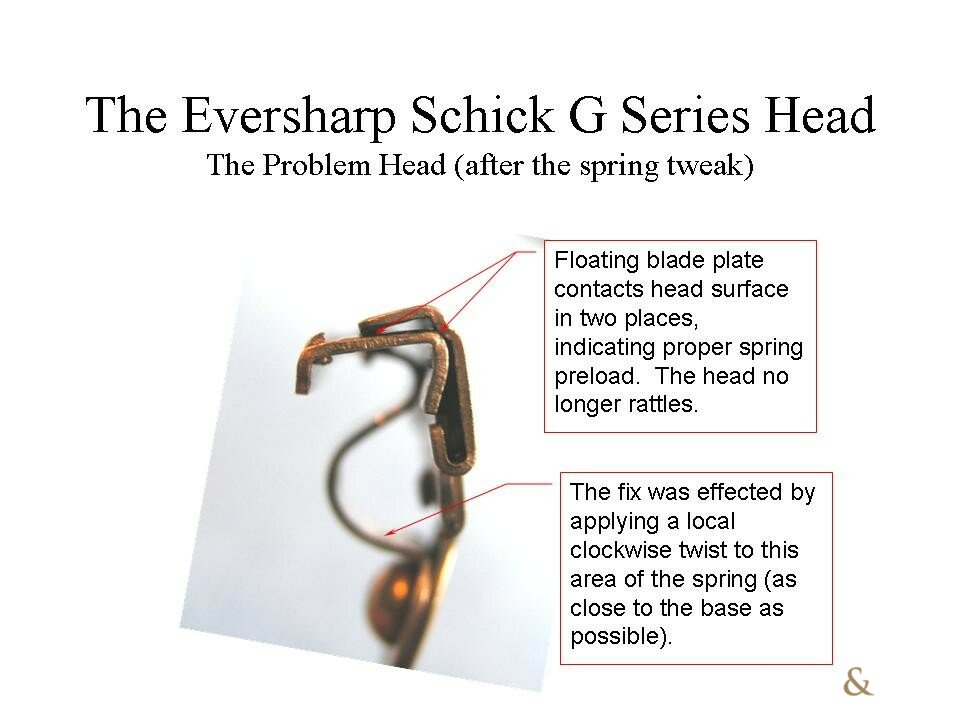

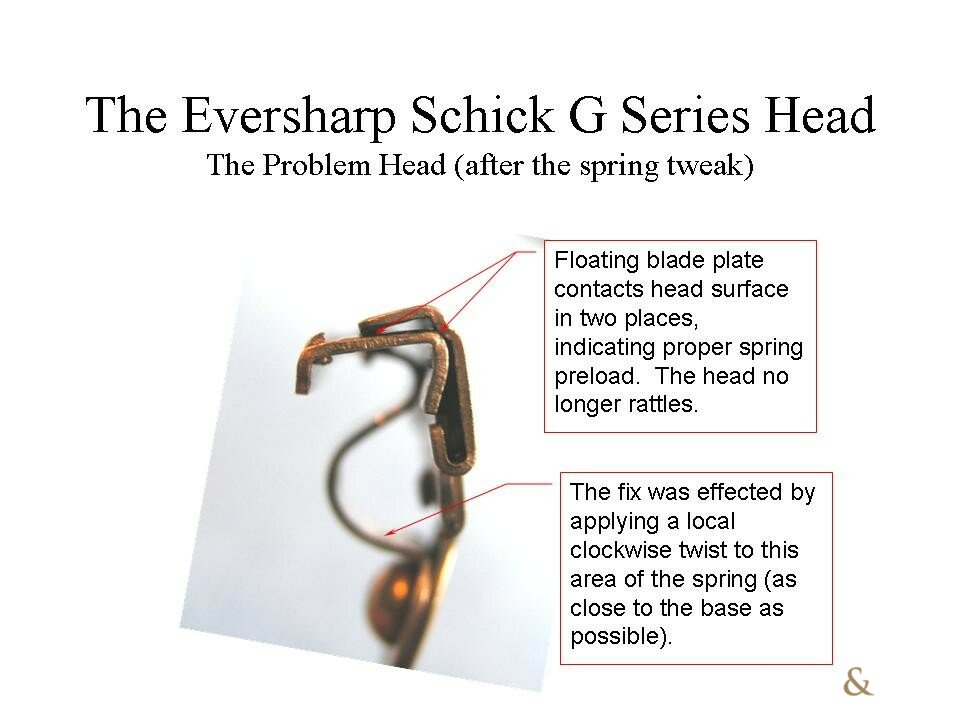

While the rivet on the problem razor was slightly loose, it appeared to be soundly set and I thought there was a greater risk of damaging the (irreplaceable) rivet than of it failing to hold the spring load. With that in mind, I opted to apply a localized "tweak" (end moment) to reform the spring as close to the rivet end as possible using needle nose pliers cushioned with a rag. Alternatively I could have wrapped the spring in cloth tape to protect it.

Two or three twists of the pliers and all looseness was gone.

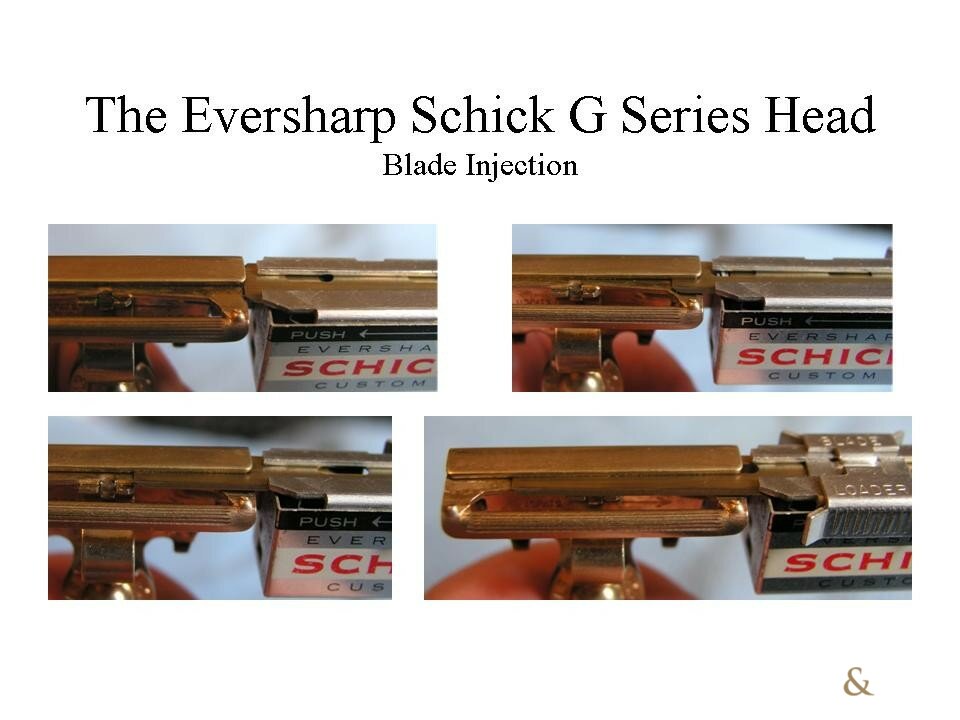

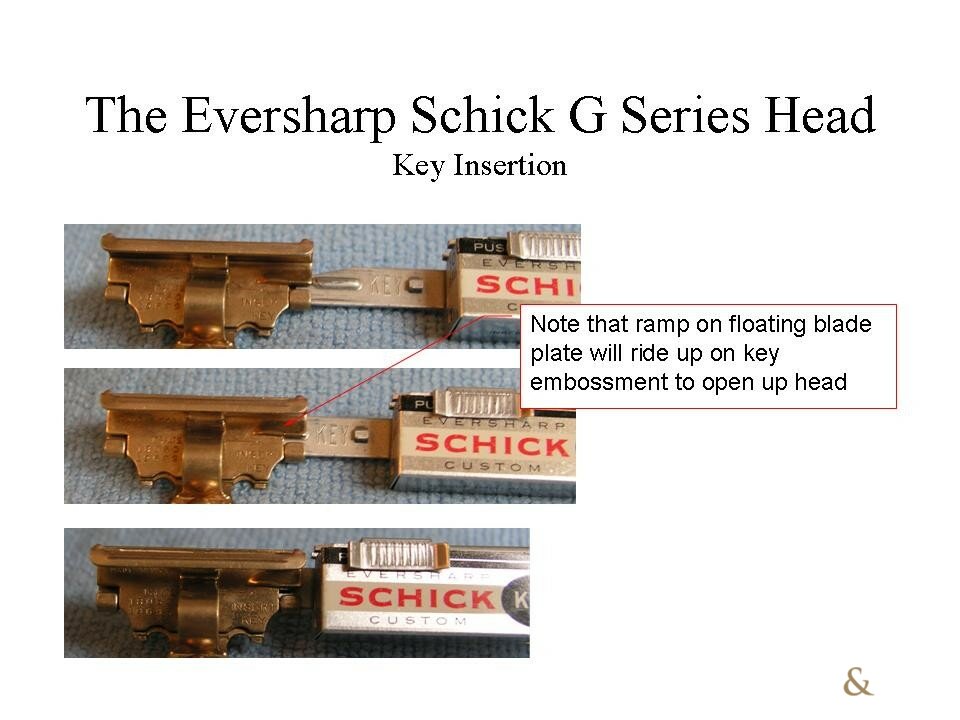

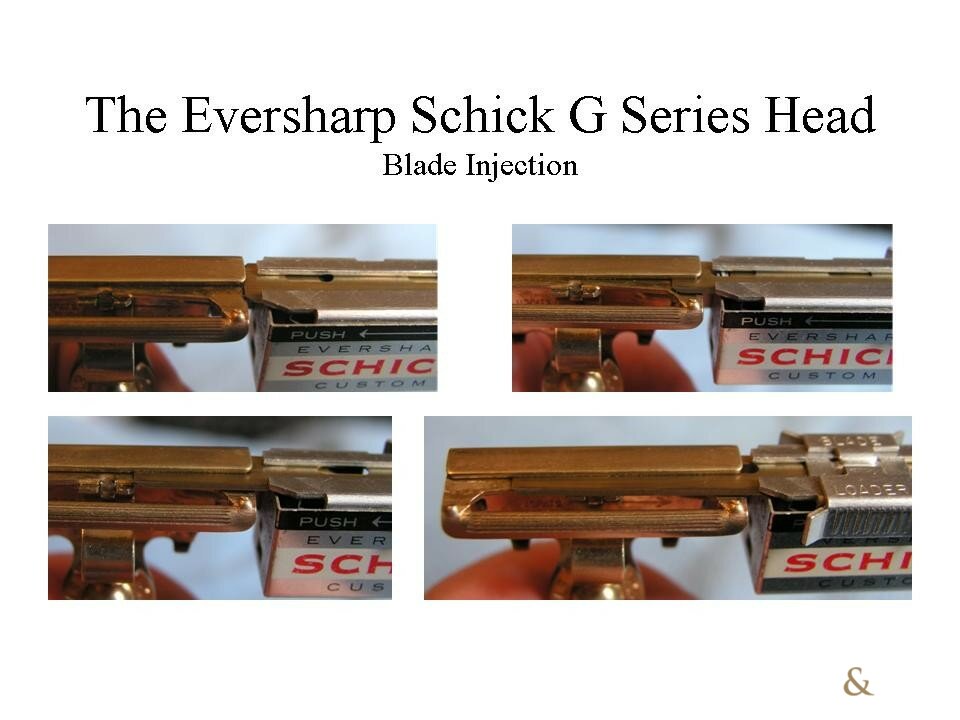

Here's my excruciating guide to injector sex. If you want music with that, you'll need to view Mantic's video.

This shows the blade entering an empty razor. This is actually hard work, since the blade has to wedge the blade cavity open as it's going in. Usually you're pushing the old blade out, to the left.

That's it for now. I welcome any questions or comments and will try to improve this posting as I mull it over.

- Chris

Recently one of our more experienced DE collectors who goes by the user name poonjaji contacted me with a concern about a gold handled G type razor that he'd received that had a very loose head. He observed that the spring rivet was loose and I suggested how he could re-set the rivet using a bearing ball and a vice-grips tool. Much to my surprise, he ultimately just sent me the razor. I decided that I should document this particular razor fix so that people would feel a little less queasy about approaching these razors.

First, there's a good reference for identifying the various models of "Schick" injector razors. It can be found here. If anyone knows of other on-line references, I'll gladly add them to this posting.

To the casual observer, the Schick razors of the mid 30's to mid 40's and the Eversharp Shicks of the mid 40's to mid 50's all look to be the same design. For the sake of this article we'll treat them as more or less the same. I have, so far, only owned G type razors, so that's what you will see in the illustrations. Most of what you see here should apply also to the E type and even the very rare D and F types.

Here's a view of the underside of a G type head:

It has one "floating" part, which I've named the floating blade plate. I pulled that name out of the air. I'm open to other part names. The blade plate is held in place by a large curved spring (the big blur in the center of the figure). The early versions of the E model razor head readily allow this spring to pivot ~110° counterclockwise for removing the blade plate. The later models (including all of the G types) have the spring retained in such a way that it has to be seriously deformed before it can be pivoted. I'm convinced that many springs get damaged as people attempt to open these razors up and I strongly recommend against that practice.

Here's a side view of the head:

The beauty of the injector head design is that it allows replacement of the blade without actually handling the blade itself. As with an SE razor, the blade cutting edge is positioned by direct contact with two small protruding stops, one at each end of the safety bar. The spring plays a very important rôle here. It forces the blade forward against the stops (or the stops backward against the blade) and at the same time clamps the blade tightly to avoid blade chatter.

Since the blade is inserted from the side of the razor (pushing the old blade out ahead of it) there's a risk of drawing the new blade's edge across the nearside stop during its insertion, effectively ruining it. In order to avoid that, the injector cartridge key and key slot are designed to force the floating blade plate outward (to the left in the illustrations) while the new blade is inserted up and away from the stop.

After the cartridge key is removed, the spring forces the blade plate to the right, seating the stops against the new blade edge and rigidly clamping it in place.

The "problem" razor's head that I mentioned earlier was very loose. As you can see, the blade plate was already floating. The risk of using such a razor primarily is that the blade will "chatter". This really means that it will bite you.

It may also means that the blade won't automatically seat against the stops. Practically speaking though, once you've pressed against the safety bar the blade plate floats into its appropriate position anyway.

It may also means that the blade won't automatically seat against the stops. Practically speaking though, once you've pressed against the safety bar the blade plate floats into its appropriate position anyway.While the rivet on the problem razor was slightly loose, it appeared to be soundly set and I thought there was a greater risk of damaging the (irreplaceable) rivet than of it failing to hold the spring load. With that in mind, I opted to apply a localized "tweak" (end moment) to reform the spring as close to the rivet end as possible using needle nose pliers cushioned with a rag. Alternatively I could have wrapped the spring in cloth tape to protect it.

Two or three twists of the pliers and all looseness was gone.

Here's my excruciating guide to injector sex. If you want music with that, you'll need to view Mantic's video.

This shows the blade entering an empty razor. This is actually hard work, since the blade has to wedge the blade cavity open as it's going in. Usually you're pushing the old blade out, to the left.

That's it for now. I welcome any questions or comments and will try to improve this posting as I mull it over.

- Chris

Last edited by a moderator: