- Thread starter

- #41

So how are the new scales coming along? I hope you show some pictures for that....I have a razor I'd like to rescale, and any info would be helpful.

--Matt

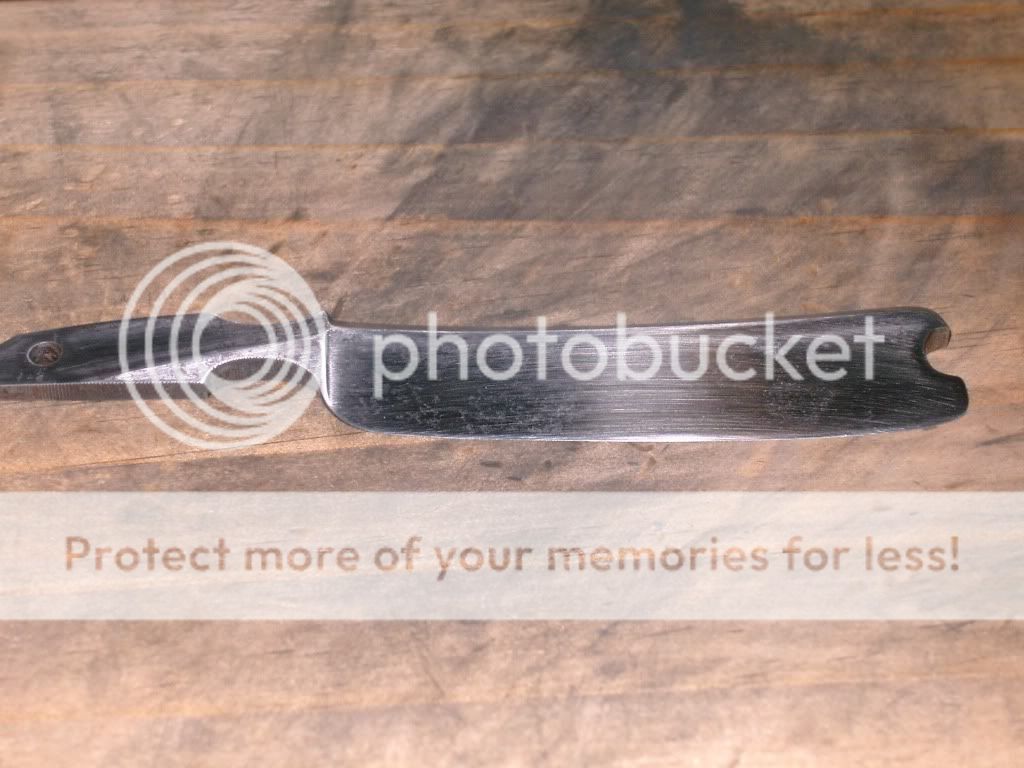

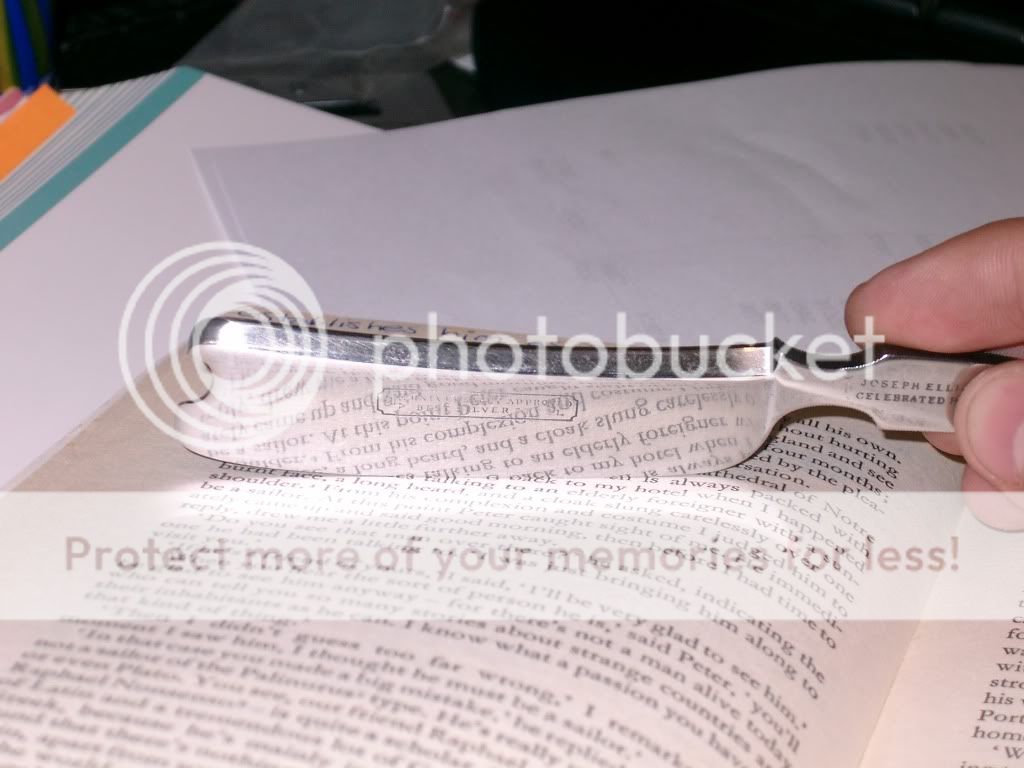

Im yet to make scales myself - ive got some time on a bandsaw and with drill presses etc next week, so im going to knock them out then.

I'll report back here for you with any lessons learnt

, ill keep you in mind if i let it go though

, ill keep you in mind if i let it go though

.

.