As http://wiki.badgerandblade.com/Tech says the safety bar was important. But the key manufacturing innovation was the stamped plate, which eventually made its way into TTO designs too.

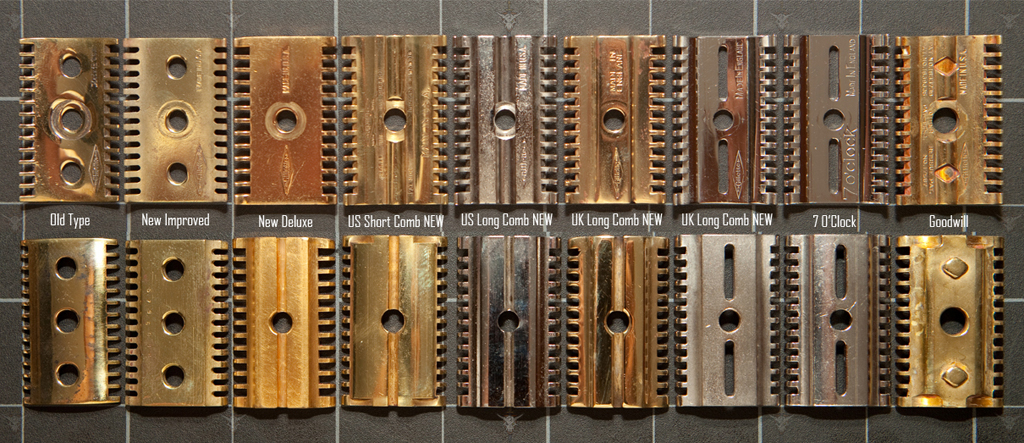

The plate is clearly stamped, and the cap and handle are also in the style of a Tech. So while an open-comb Tech sounds like an oxymoron, that is what I would call it. Possibly it was made as an experiment, with an eye to keeping an entry-level open-comb in the UK product line? The UK factory made quite a few variations on the standard NEW design, too.

Those stamped teeth look like they might be uncomfortable to use. How does it shave?

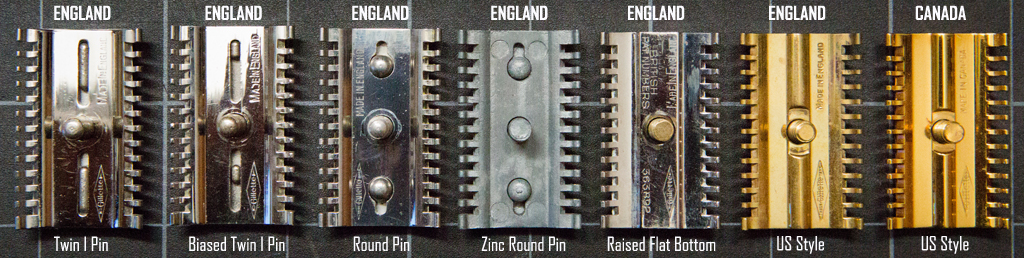

The Gillette Tech was notable as the first Gillette razor sold with a solid safety bar rather than an open comb guard. From a manufacturing standpoint, the Tech was the first safety razor made with a guard plate stamped from sheet metal. Previously guard plates had been machined or swaged (die-forged) from stock. This technique was patented as US 2,270,388, filed 9 Aug 1938 and issued 20 Jan 1942, and gave the Tech its characteristic diamond-indented guard plate. This depression stiffens the plate. Some UK variants do not have this feature, and may have been stamped from thicker sheet-metal, or may have been machined or swaged.

The plate is clearly stamped, and the cap and handle are also in the style of a Tech. So while an open-comb Tech sounds like an oxymoron, that is what I would call it. Possibly it was made as an experiment, with an eye to keeping an entry-level open-comb in the UK product line? The UK factory made quite a few variations on the standard NEW design, too.

Those stamped teeth look like they might be uncomfortable to use. How does it shave?