You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Escher/Thuringian love. show of your rocks

- Thread starter raccoonandbrush

- Start date

I'll take three 125 x 65 mm stones  . Hard to believe the price.

. Hard to believe the price.

@Frank Shaves , you have a little Thuri, right? How have you been getting along with it?

@Frank Shaves , you have a little Thuri, right? How have you been getting along with it?

I now have two Thuris: a small bout I got from Peter, and a 5 x 2.5 mottled blue green. I have now had a few sharp smooth edges, but I also tried thicker slurry one time and ended up with some deeper scratches. I have bought too much stuff recently and need to get back to the Thuris.

I highly recommend you try a Thuri. They are wonderful stones, capable of very smooth edges.

I've only ever put a light slurry on my, VERY LIGHT. Barely visible. And the edge was amazing and I didn't expect much. I redid it under running water the next day and it became crazy sharp, like equal to a black ark sharp, which I was unaware thuringians could do. The edge was aggressive and left some red bumps when I applied any pressure. Im going to try a very light slurry from a soft lpb coti slurry stone tonight. The thuri is very soft much softer than my apex water hone, is imagine it's about equal to my green thuri so I'm hoping to get a little mix of each in it so the edge is aggressive and butter smooth. The first time I slurries it I use my new la lune slurry stone, I know it's much harder than the thuri so that was all thuri slurry. My thuri is easily scratched with a knife, with light- normal pressure. I wish I could find a thuri bout that's about 2/3 hand sized or a y/g barbers delight with slurry stone. I don't care about label if the stones is confirmed.I now have two Thuris: a small bout I got from Peter, and a 5 x 2.5 mottled blue green. I have now had a few sharp smooth edges, but I also tried thicker slurry one time and ended up with some deeper scratches. I have bought too much stuff recently and need to get back to the Thuris.

I highly recommend you try a Thuri. They are wonderful stones, capable of very smooth edges.

Hello guys,

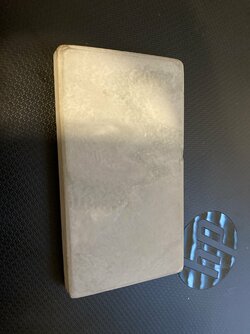

I recently bought this stone for £ 40. It should be Thuringian slate from Germany, according to the seller. The dimensions of the stone are 203x47mm, the thickness is between 10 and 15mm. The stone is dark gray in color, definitely finer than Tsushima Nagura or BBW or MST Müller slate. One side is flat, the other used concave with scratches. On cut sides are specific saw marks.

I think this is a Thuringian hone from Faso, according to saw marks and size.

While searching, I found old Faso stone with same saw marks and dimensions of 20x4.5x1.8 cm.

What is your opinion? is it really Faso hone?

I'm wondering what to do with the concave side......leave it as is / flatten it / fill hollow with epoxy

What is your recommendation?

View attachment 1443504View attachment 1443505

Coming back to that issue, some more informations that might help.

So in general thuringian hones have been cut directly after their mining by the miners – normally not by any sales company. All classic thuringians are coming from a few quarries around the small town Steinach in Thuringia. Miners had been most of the time very small family companies that sold the stones to larger sales company. During a long time mining and sale of thuringian hones had been strictly devided by authority, means the miners could only sell the stones to sale campanies, the sale companies were not allowed to mine stones.

In the 18th and 19th century the miners cut the stones in small workshops located directly near the quarries. They were cut by hand what you can see at the typical irregular and straight saw marks. End of the 19th century and in the 20th century the stones were cut by circular saws. The sawmarks are typicla equal and curved. Depending on the size of the saw, the spaces between the saw teeth and the speed, the stones were moved through the saw, the sawmarks are more or less large and equal.

The sawmarks on your stone are very equal, the distance is small. That is typical, if the forward move of the stone through the saw is made by machine not by hand. So in my opinion the stone was produced later in the 20th century but before WW2 if it is an original classic thuringian.

Coming back to the FASO company. Fassbinder Solingen was found in 1906. They sold hones like the famous Goldfisch Wetzstein, Arkansas and belgium hones. In their early time they also sold original thuringian hones which they bought like all other companies from the miners in Thuringia.

Later on they sold their typical labelled FASO Waterhone. But these hones are not the classic thuringian hones, they are coming from another quarry located elsewhere. Indeed these stones do have very typical small and close sawmarks. But these FASO hones are all very dark blue slate hones.

What you show in your pictures, at least what I can recognize, is a typical dark grey original thuringian hone.

Here is an older thread from me, where I tested a typical FASO hone:

German FASO water hones

Sebastian (Doorsch) sent me this hone for testing. It is quite an interesting hone. I have seen these Fasos quite a lot in former years but less the last times. Reports on the type of stone and the performance of Faso labeled hones in different forums showing no uniform picture of...

www.badgerandblade.com

www.badgerandblade.com

And here is some more information of our member Doorsch tot he Fassbinder company:

Fassbinder and Co. Solingen (F&Co.)

To document a bit more on the history of the Solingen based company i thought i should start a seperate thread to keep the information strictly together here. After the Member from SRP Thomas aka Bart Ab posted more information on the shortcut F&Co. Which sold the F&Co. Goldfisch Wetzstein and...

www.badgerandblade.com

www.badgerandblade.com

Best regards

Peter

Coming back to that issue, some more informations that might help.

So in general thuringian hones have been cut directly after their mining by the miners – normally not by any sales company. All classic thuringians are coming from a few quarries around the small town Steinach in Thuringia. Miners had been most of the time very small family companies that sold the stones to larger sales company. During a long time mining and sale of thuringian hones had been strictly devided by authority, means the miners could only sell the stones to sale campanies, the sale companies were not allowed to mine stones.

In the 18th and 19th century the miners cut the stones in small workshops located directly near the quarries. They were cut by hand what you can see at the typical irregular and straight saw marks. End of the 19th century and in the 20th century the stones were cut by circular saws. The sawmarks are typicla equal and curved. Depending on the size of the saw, the spaces between the saw teeth and the speed, the stones were moved through the saw, the sawmarks are more or less large and equal.

The sawmarks on your stone are very equal, the distance is small. That is typical, if the forward move of the stone through the saw is made by machine not by hand. So in my opinion the stone was produced later in the 20th century but before WW2 if it is an original classic thuringian.

Coming back to the FASO company. Fassbinder Solingen was found in 1906. They sold hones like the famous Goldfisch Wetzstein, Arkansas and belgium hones. In their early time they also sold original thuringian hones which they bought like all other companies from the miners in Thuringia.

Later on they sold their typical labelled FASO Waterhone. But these hones are not the classic thuringian hones, they are coming from another quarry located elsewhere. Indeed these stones do have very typical small and close sawmarks. But these FASO hones are all very dark blue slate hones.

What you show in your pictures, at least what I can recognize, is a typical dark grey original thuringian hone.

Here is an older thread from me, where I tested a typical FASO hone:

German FASO water hones

Sebastian (Doorsch) sent me this hone for testing. It is quite an interesting hone. I have seen these Fasos quite a lot in former years but less the last times. Reports on the type of stone and the performance of Faso labeled hones in different forums showing no uniform picture of...www.badgerandblade.com

And here is some more information of our member Doorsch tot he Fassbinder company:

Fassbinder and Co. Solingen (F&Co.)

To document a bit more on the history of the Solingen based company i thought i should start a seperate thread to keep the information strictly together here. After the Member from SRP Thomas aka Bart Ab posted more information on the shortcut F&Co. Which sold the F&Co. Goldfisch Wetzstein and...www.badgerandblade.com

Best regards

Peter

Peter, thanks for your analysis and other useful information. I'm glad that you consider this stone as original Thuringian.

I lapped the flat side of the stone. The new surface is a slightly lighter shade of gray than before and it's very uniform. I can see very very light soft shadow of the marbling from one specific angle. (impossible to capture on photo)

I'm getting used to the stone. I am trying some naguras because the stone did not come with a slury stone. (I tried Tsushima Nagura, Gujo Nagura, Nakayama kiita, Ozuku Mizu Asagi, coticule, fine BBW and so on) It seems that the best combination is with Shobudani Nashiji or with synthetic Morihei extra fine nagura (surprice for me).

Tom messaged me today and sent me a link to an eBay post showing a period advertisement for the above stone.

Thank you Tom.

Got lucky on this one. It was facing down in the box and all I could see was blue in the pictures.

It was a nice surprise to pull it out of the box and see a beautiful natural combo. 8 x 1 3/4

It was a nice surprise to pull it out of the box and see a beautiful natural combo. 8 x 1 3/4

I got this about a year ago. It was sold as possibly a reform thuringian or maybe a very light thuringian. I was skeptical, but now I realize that the seller was probably Ian @SliceOfLife That’s good enough for me. First pic is with dry slurry

I'd bet the remaining half of my left thumb that that stone is natural. Is it soft? It's the lightest one I've seen, all the reform ones I've seen are dark blue(or black). I'd assume it's because those are the lower layers. My (grey?)green one is way softer than the blue ones and it's performance is outstanding. I've been hooked since I tried it and I've completely shunned thuris for the last year because of an "apex water hone" that I wholly suspect I messed up by embedding diamonds into it. I've rubbed the hell out of it and it's much much smoother and more like the blue "genuine thuringian water hone" I bought recently. I think the apex needs a couple more knives. The blues I have are very hard like arks, but more fragile like coticules(or the looks of the chips are the same so I assume, though I've easily chipped very hard slates). If that is a natural stone and it is a thuri(im sure from @SliceOfLife ) and if it's very, very good I'd say to send the man fruit basket, with a 24 year old scotch core! Because you were gifted a unicorn by someone with passion for the entirety of skills it takes to make straight shaving possible. From tanning certain leathers for certain steels, to breaking your back digging rock from the earth. Have faith in the veterans, especially in this community. I've learned insane amounts of things here and most aren't directly related to straight shaving only, and the hone page is the ONLY one I visit. And I've learned entirety about straight shaving but so much more. You've got a unicorn lad, enjoy!

Edited for clarity due to Mexican lagers.

Last edited:

It is pretty soft. I’m not sure if it’s softer or harder than a yg, but but softer than a dab. It feels more porous during use, but now I tested it side by side with a db Escher and a yg from Peter.

It looks like it’s less porous than both of them. The slurry dries out fast though, so that might be why it feels like it’s lapping up water. Wierd.

The weight (hand feel) is heavier than the Escher on top even though it’s smaller, so maybe it’s denser (maybe that’s why it’s taking longer to absorb).

It looks like it’s less porous than both of them. The slurry dries out fast though, so that might be why it feels like it’s lapping up water. Wierd.

The weight (hand feel) is heavier than the Escher on top even though it’s smaller, so maybe it’s denser (maybe that’s why it’s taking longer to absorb).

Yeah everything about that rock screamed reform to me except if memory serves, acid did nothing to it (even rather strong acids).

What's this acid trick?Yeah everything about that rock screamed reform to me except if memory serves, acid did nothing to it (even rather strong acids).

If it bubbles it is reacting with the binder.What's this acid trick?

No bubbles, it is a natural as natural stones do not have a binder.

Good little trick.

I think some sandstones bubble too, because the binder that the acids typically react to can be a naturally occurring substance with a high ph (I think it's calcium carbonate or something like that, too lazy to try and remember my chemistry at the moment)... but MOST natural stones don't bubble and most vintage synths (and many modern synths) do.

Very clever, bravo!If it bubbles it is reacting with the binder.

No bubbles, it is a natural as natural stones do not have a binder.

Good little trick.

To most geologists, the term "acid test" means placing a drop of dilute (5% to 10%) hydrochloric acid on a rock or mineral and watching for bubbles of carbon dioxide gas to be released. The bubbles signal the presence of carbonate minerals such as calcite, Dolomite, or one of the minerals. The bubbling release of carbon dioxide gas can be so weak that you need a hand lens to observe single bubbles slowly growing in the drop of hydrochloric acid - or so vigorous that a flash of effervescence is produced. These variations in effervescence vigor are a result of the type of carbonate minerals present, the amount of carbonate present, the particle size of the carbonate, and the temperature of the acid.

Some rocks contain carbonate minerals, and the acid test can be used to help identify them. Limestone,Dolostone and Marble. Some stones are bound together with minerals such as calcite or dolomite and will also effervesce.

Some rocks contain carbonate minerals, and the acid test can be used to help identify them. Limestone,Dolostone and Marble. Some stones are bound together with minerals such as calcite or dolomite and will also effervesce.

Can I use vinegar instead of hydrochloric acid? A site that describes the acid test as above says that you can substitute vinegar but it’ll have a less noticeable reaction. Anyone tried it for this purpose?To most geologists, the term "acid test" means placing a drop of dilute (5% to 10%) hydrochloric acid on a rock or mineral and watching for bubbles of carbon dioxide gas to be released. The bubbles signal the presence of carbonate minerals such as calcite, Dolomite, or one of the minerals. The bubbling release of carbon dioxide gas can be so weak that you need a hand lens to observe single bubbles slowly growing in the drop of hydrochloric acid - or so vigorous that a flash of effervescence is produced. These variations in effervescence vigor are a result of the type of carbonate minerals present, the amount of carbonate present, the particle size of the carbonate, and the temperature of the acid.

Some rocks contain carbonate minerals, and the acid test can be used to help identify them. Limestone,Dolostone and Marble. Some stones are bound together with minerals such as calcite or dolomite and will also effervesce.

I have a little guy that seems to be a synthetic based on size and shape, but seems finer than most typical synthetic razor hones. I would love to test it and vinegar is much easier for me.

Similar threads

- Replies

- 7

- Views

- 3K