Summary

- Water hardness is explained with particular emphasis on lather and soap scum.

- Hardness classification scales for the United States and England are provided regarding soft to very hard water in terms of mg/L of equivalent CaCO3. England generally has harder water than the United States.

- A formula is developed for the fraction of Epsom salt needed with purified water for creating any reasonable water hardness.

- Simple recipes are presented for making a 4000 mg/L hard water stock with Epsom salt and distilled water and then making test waters with various hardnesses using the hard water stock in combination with distilled water. Amounts are provided in both volume and mass.

- Experimental results, with photographs, are presented for two shaving soaps and lathers made with test waters having hardnesses of 0 mg/L, 100 mg/L, 250 mg/L, 500 mg/L, and 1000 mg/L, which covers a wide range of values. It was found that, seemingly irrespective of the soap, increasing water hardness results in less slickness and a drier post-shave. Further, the use of softer or harder water may or may not be visible to the naked eye. Depending on the soap, the lather might appear the same or it might develop larger air cells and become less stable with increasing water hardness. The effects of water hardness on lather quality for shaving soaps are reasonably presumed to apply similarly for shaving creams.

- Advice is provided for those wishing to experiment with water hardness effects on lather quality.

- Distilled water is recommended as the simplest water option for making better lather with respect to slickness, cushion, and post-shave, but adding citric acid to tap water could be beneficial.

Introduction

Water is chemically known as H2O, but that doesn't make it all the same. Water has a fantastic ability to dissolve minerals, and this phenomenon especially occurs when groundwater flows through soil and rock. Whether from a ground or surface source, water ends up with small amounts of naturally occurring minerals, particularly calcium and magnesium. More dissolved calcium and magnesium means that water has more "hardness", more capacity to precipitate soap and less capability of producing suds with soap. In fact, when soap is added to water, the calcium and magnesium ions present in the water react in an interchangeable way with the sodium and potassium salts in the soap and form calcium and magnesium salts, better known as "soap scum" [1]. Thus, harder water not only makes forming lather generally more difficult, it also unfortunately has a greater potential for producing soap scum, which can also affect a shave. Softer water, on the other hand, is generally easier to use when building lather while being less likely to yield soap scum, giving softer water a better reputation among traditional shavers.

Definition of Water Hardness

Hardness of water is primarily caused by calcium and magnesium ions, but a variety of other dissolved metallic ions may contribute. Even though hardness is truly determined by the precise mixture of dissolved minerals, together with the water's pH and temperature, hardness is typically defined as the sum of the concentrations of calcium and magnesium ions expressed by an equivalent concentration of calcium carbonate (CaCO3) in milligrams per liter (mg/L) or parts per million (ppm) [2].

Dissolved minerals can either cause temporary or permanent hardness. Temporary hardness is caused by the presence of dissolved bicarbonates that can be converted to insoluble carbonates by boiling the water, precipitating carbonates from the solution. Permanent hardness is caused by chlorides and sulfates that cannot be removed via boiling [2]. Conventionally, water softeners are used to reduce hardness by replacing dissolved calcium and magnesium ions with dissolved sodium or potassium ions, which are more compatible with soap and plumbing [3]. Adding citric acid to water lowers its pH value and has little effect on mineral content, but by the process of chelation, citric acid binds dissolved minerals and reduces the formation of soap scum and scale [4]. This explains the advice that a little citric acid be added to water in order to soften it for building lather and using while shaving [5]. EDTA is another common chelator [4], but citric acid is natural, relatively inexpensive, and widely available where canning supplies are sold.

In the United States, water with equivalent hardness of ≤60 mg/L as calcium carbonate is generally classified as "soft", >60 mg/L and ≤120 mg/L as "moderately hard", >120 mg/L and ≤180 mg/L as "hard", and >180 mg/L as "very hard" [6]. This classification corresponds with an approximate median value of 120 mg/L with relatively few places having hardness values that reach over 1000 mg/L. Softer waters are generally found in the Northeast, the Southeast, and the West in the Pacific Time Zone, while harder waters are generally found in the Midwest, the Southwest, and the West in the Mountain Time Zone [7]. In England, with water hardness generally increasing from northwest to southeast with an approximate median value of 200 mg/L, water is typically harder than in the United States and, therefore, follows a different classification scale: ≤50 mg/L is "soft", >50 mg/L and ≤100 mg/L is "moderately soft", >100 mg/L and ≤150 mg/L is "slightly hard", >150 mg/L and ≤200 mg/L is "moderately hard", >200 mg/L and ≤300 mg/L is "hard", and >300 mg/L is "very hard" [8].

Formula for Epsom Salt Fraction Given Desired Water Hardness

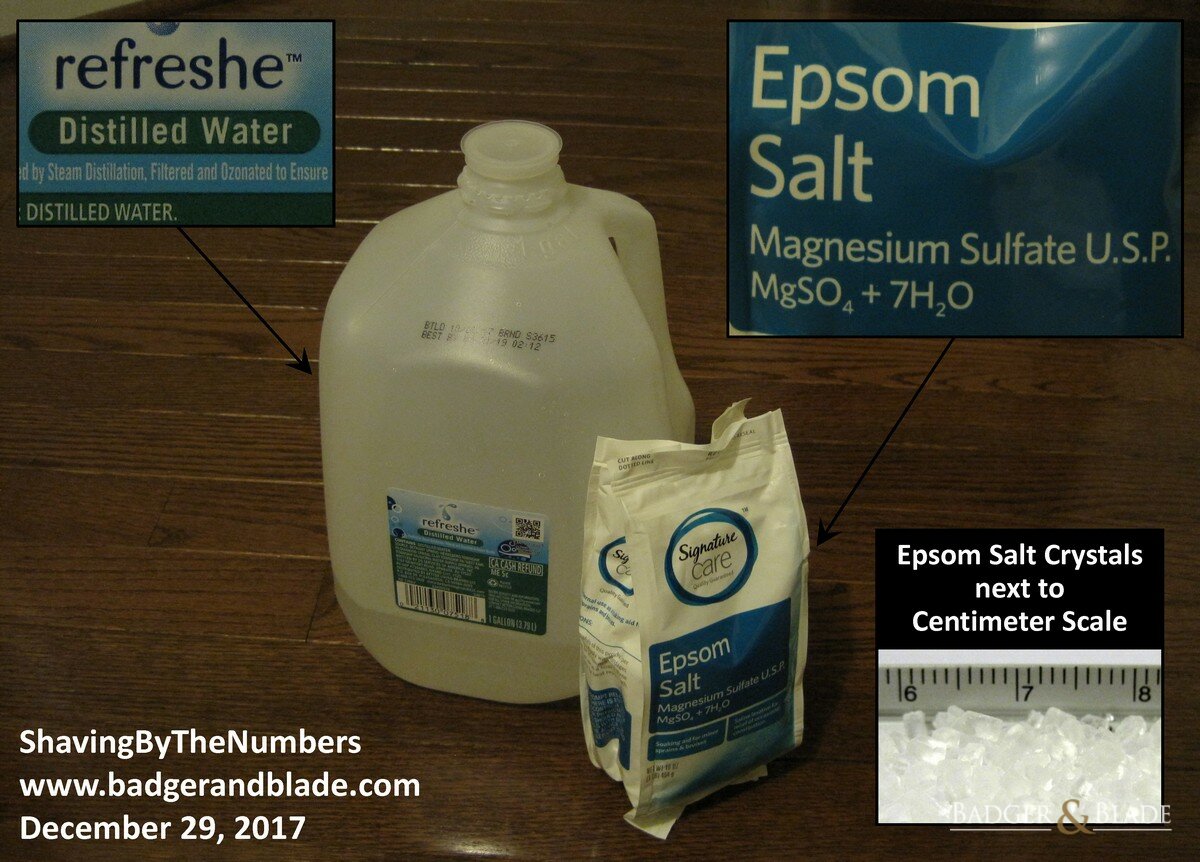

In order to perform controlled experiments on the effects of water hardness on lather, test waters with desired hardnesses must be used. This can be accomplished by adding specific amounts of hardening ingredients to purified water [9], such as distilled water, which serves as a reference with negligible hardness. There are different ingredients that can be used to increase the hardness of water, but the only readily available item that I could identify is Epsom salt. Distilled water and Epsom salt are shown below. The grain size of Epsom salt can be observed as very large compared to normal granulated sugar and salt.

(Click on image for full-resolution version)

Epsom salt is chemically known as magnesium sulfate heptahydrate (MgSO4⋅7H2O), a hydrated form of magnesium sulfate (MgSO4). With many purposes, including medicinal and agricultural, Epsom salt can be inexpensively purchased in grocery, drug, and home improvement stores. Given the desire to use Epsom salt with distilled water, another readily available and inexpensive item, I developed a formula for the fraction of Epsom salt needed to cause a desired equivalent water hardness as calcium carbonate. Such a formula seemed to be unavailable on the Internet.

Developing a formula involved the molar masses of Epsom salt (MgSO4⋅7H2O) and calcium carbonate (CaCO3), which are 246.466 g/mol [10] and 100.086 g/mol [11], respectively, based on standard atomic weights [12] and conventional atomic weights [13] for elements with standard atomic weights that are defined as intervals rather than single values. A simple ratio of molar masses is used when calculating the equivalent mass of calcium carbonate for a given mass of Epsom salt. The mass of Epsom salt is safely assumed to be negligible compared to the mass of purified water, and the volume change with the addition of Epsom salt is also assumed to be negligible. Air-saturated pure water has a density of 998.20426 g/L at 20 °C and 1 atm [14], based on the International Committee of Weights and Measures (CIPM) standard, and with the aforementioned simplifications, an approximate formula was developed for the fraction of Epsom salt needed to increase hardness by a given equivalent value in mg/L as calcium carbonate (CaCO3):

| Fraction of Epsom Salt to Purified Water as Function of Equivalent Hardness in mg/L as Calcium Carbonate (CaCO3) | ||

| Epsom Salt Fraction* | = | [(246.466 g/mol MgSO4⋅7H2O) / (100.086 g/mol CaCO3 × 998.20426 g/L H2O × 1000 mg/g)] × Hardness |

| = | 0.00000246697 × Equivalent Hardness in mg/L as CaCO3 | |

The ASTM standard [15] for making test waters with desired hardnesses is noteworthy. This standard involves a "synthetic hard water stock" that is made with 12.14 g of anhydrous calcium chloride (CaCl2) and 5.55 g of magnesium chloride hexahydrate (MgCl2⋅6H2O) in a one-liter solution with Type IV grade reagent water, such as distilled water, at 20 °C. The synthetic hard water stock is stated as having a hardness of 13,680 mg/L as calcium carbonate (CaCO3) with a compositional ratio of 4:1 calcium carbonate (CaCO3) to magnesium carbonate (MgCO3). Calculations were performed using molar masses to verify the ASTM standard and validate my formulation methodology. Examples on the Internet regarding the use of Epsom salt with coffee and brewing water were used for further validation.

Suggested Recipes for Test Waters that Cover a Wide Range of Hardness Values

The formula developed in the previous section will give the proportion of Epsom salt needed to yield any reasonable water hardness, but in the real world, using the formula can be troublesome. For smaller water hardnesses and smaller amounts of water, the mass of Epsom salt can be too small to accurately measure due to Epsom salt's relatively large grain size and/or the measuring tool's resolution that might be too large. Assuming a desired water hardness of 50 mg/L with one cup of distilled water, for example, yields 0.0291 g of Epsom salt, which is impossible to measure with any accuracy using a normal 0.01 g resolution scale. Starting with an accurately measured mass of Epsom salt significantly larger than 0.0291 g would result in a calculated amount of water significantly larger than one cup, which could require a considerable and wasteful amount of purified water.

In order to easily make smaller amounts with smaller hardnesses, an accurate hard water stock can be utilized. The synthetic hard water stock, with a relatively large hardness, can be accurately made with sufficient amounts of Epsom salt and purified water following the formula in the previous section. Then, as employed in the aforementioned ASTM standard, portions of the hard water stock can be mixed with purified water to create solutions with a wide range of hardness values. For instance, if one part of a hard water stock is added to three parts of purified water, then the solution would be one part hard water stock out of four parts total, resulting in a solution with 25 % of the hardness of the hard water stock. When correctly applied, this method avoids inaccurate measurements of very small amounts of Epsom salt while allowing for accurate test waters to be made with more efficient use of materials.

Measuring mass with a scale is generally more accurate than measuring volume, but a scale might be unavailable. In homes throughout the United States, measuring volume with measuring spoons and cups is commonplace. Both measurement methods should be addressed so that users that wish to test the effect of water hardness on lather quality can do so with ease. To this end, easy-to-use recipes have been created for making test waters with either volume or mass measurements. The suggested recipes involve first making a 4000 mg/L synthetic hard water stock with Epsom salt and purified water, following the first table below, and then the second table can be followed for making different test waters with desired hardnesses by combining prescribed amounts of the hard water stock and purified water.

| Synthetic Hard Water Stock with Equivalent Hardness of 4000 mg/L as Calcium Carbonate (CaCO3), Made with Epsom Salt and Distilled Water | |||

| Volume* | Mass† | ||

| Epsom Salt | Distilled Water | Epsom Salt | Distilled Water |

| 1 t | 2 C + 2 T + 1 1/2 t | 5.02 g | 508.68 g |

| 2 t | 4 1/4 C + 2 3/4 t | 10.04 g | 1017.36 g |

†Mass measurements, especially with higher-resolution scales, are often more accurate than volume measurements.

| Test Waters with Different Equivalent Hardnesses in mg/L as Calcium Carbonate (CaCO3), Made with 4000 mg/L Stock and Distilled Water | ||||

| Hardness | Volume* | Mass† | ||

| 4000 mg/L Stock | Distilled Water | 4000 mg/L Stock | Distilled Water | |

| 0 mg/L | 0 C | >0 C | 0 g | >0 g |

| 50 mg/L‡ | 1/2 t | 3/4 C + 1 T + 1/2 t | 2.46 g | 194.34 g |

| 60 mg/L§ | 3/4 t | 1 C + 1 1/4 t | 3.69 g | 242.31 g |

| 100 mg/L‡ | 1 t | 3/4 C + 1 T | 4.92 g | 191.88 g |

| 120 mg/L§ | 1 1/2 t | 1 C + 1/2 t | 7.38 g | 238.62 g |

| 150 mg/L‡ | 1 1/2 t | 3/4 C + 2 1/2 t | 7.38 g | 189.42 g |

| 180 mg/L§ | 2 1/4 t | 3/4 C + 3 T + 2 3/4 t | 11.07 g | 234.93 g |

| 200 mg/L‡ | 2 t | 3/4 C + 2 t | 9.84 g | 186.96 g |

| 250 mg/L | 1 T | 3/4 C + 3 T | 14.76 g | 221.40 g |

| 300 mg/L‡ | 1 T | 3/4 C + 1 t | 14.76 g | 182.04 g |

| 500 mg/L | 2 T | 3/4 C + 2 T | 29.52 g | 206.64 g |

| 750 mg/L | 3 T | 3/4 C + 1 T | 44.28 g | 191.88 g |

| 1000 mg/L | 1/4 C | 3/4 C | 59.04 g | 177.12 g |

| 1500 mg/L | 1/4 C + 2 T | 1/2 C + 2 T | 88.56 g | 147.60 g |

| 2000 mg/L | 1/2 C | 1/2 C | 118.08 g | 118.08 g |

| 3000 mg/L | 3/4 C | 1/4 C | 177.12 g | 59.04 g |

| 4000 mg/L | >0 C | 0 C | >0 g | 0 g |

†Mass measurements, especially with higher-resolution scales, are often more accurate than volume measurements.

‡In England, water with hardness of ≤50 mg/L is classified as "soft", >50 mg/L and ≤100 mg/L as "moderately soft", >100 mg/L and ≤150 mg/L as "slightly hard", >150 mg/L and ≤200 mg/L as "moderately hard", >200 mg/L and ≤300 mg/L as "hard", and >300 mg/L as "very hard". This classification corresponds with an approximate median value of 200 mg/L.

§In the United States, water with hardness of ≤60 mg/L is generally classified as "soft", >60 mg/L and ≤120 mg/L as "moderately hard", >120 mg/L and ≤180 mg/L as "hard", and >180 mg/L as "very hard". This classification corresponds with an approximate median value of 120 mg/L.

The first table employs a minimum volume measurement of one teaspoon (1 t) for Epsom salt because of its relatively large grain size. Typical Epsom salt is reported as having a magnesium content of 495 mg per teaspoon, which corresponds, using molar masses, to a density of (246.466/24.305) × 495 mg per teaspoon = 5.02 g/t = 241 g/C, where one cup (1 C) is equal to 48 teaspoons. The author experimented with repeated mass measurements of Epsom salt using measuring spoons and cups ranging from 1/8 t to 1/2 C, such that Epsom salt amounts were leveled with the tops of the volume measurement tools using a straight edge. As expected, the measured density was generally found to become less consistent and more inaccurate as the volume increment decreased. For 1/2 C and 1 t measurements, the average measured density was only about 1 % and 3 % off, respectively, from the reported density, and the standard deviation in repeated measurements was 2.5 % and 3.3 %, respectively, of the average measurement. Measuring spoons smaller than 1 t resulted in more inconsistency and considerable inaccuracy. Measurements in 1/2 t increments, for example, resulted in an average measured density that was about 19 % larger than the reported density, and the standard deviation in repeated measurements was 4.5 % of the average measurement. Thus, volume measurements of Epsom salt in 1 t or larger increments were deemed as acceptable, although generally not as accurate as mass measurements.

The second table shows volumes and corresponding masses for a 4000 mg/L stock and purified water in order to make waters of various hardness, particularly associated with water classification scales in the United States and England. Approximate median hardness values for those areas are included among the various options for extremely soft to extremely hard water, such that the largest water hardness is beyond what can be reasonably encountered for drinking water. The total volume in each recipe is generally around one cup and involves at least 1/2 t of hard water stock for reasonable accuracy when measuring volume, but at least doubling a recipe and using larger volume measurement tools and/or larger measurements would be expected to increase accuracy of the resulting water hardness. Density of the hard water stock is approximately the same as for purified water, since the amount of Epsom salt is relatively negligible, as previously discussed. Water density is taken as 998.20426 g/L × 0.2365882365 L/C [16] = 236 g/C.

Experimental Setup with Exact Lathers Built Using Test Waters of Different Hardness

Following the principles established above, test waters with different hardnesses were created with Epsom salt and distilled water for studying the effects of water hardness on lather building and shaving. One gallon of distilled water and one pound of Epsom salt were purchased for approximately $1 and $2, respectively. Epsom salt and distilled water masses were measured to precision with the appropriate calibrated scales and mixed together to produce a set of five test waters with approximate equivalent hardnesses of 0 mg/L, 100 mg/L, 250 mg/L, 500 mg/L, and 1000 mg/L as CaCO3, with 1000 mg/L being extreme and significantly greater than median values in the United States and England. As pictured below, the test waters were contained in plastic bottles with flip top caps for fairly precise dispensing when making lathers.

(Click on image for full-resolution version)

Experiments were conducted with two very different shaving soaps in the opinion of the author: L&L Grooming (unscented) and Mitchell's Wool Fat. Each soap was tested with each test water. Following optimization results in the opinion of the author, each lather with L&L Grooming was made with 1.0 g of soap and 8.5 g of test water [17], while each lather with Mitchell's Wool Fat was made with 0.27 g of soap and 6.75 g of test water [18], meaning that the only variable in each set of tests was water hardness.

Lathers were consistently built in each set following my exact lathering method, such that masses of soap and water were measured into a lathering bowl and lathers were built in the bowl with an initially dry synthetic-hair brush to avoid water transfer with natural bristles [19], but lathers could be built in any consistent manner for controlled experiments. Lather building times were consistent within each experimental set. After each lather was built, it was used in a shave with the same razor and blade, with the exception that new blade samples were used at the start of each set. The Kai blade that was new at the start of each set was kept in the razor during each set, becoming more used with each shave while maintaining fairly consistent quality. A Bevel safety razor, modified with two layers of tape strips under the cap edges and one shim under the blade to decrease the blade exposure to effectively neutral, make the guard span smaller, and increase the blade rigidity [20], was used for testing. Test waters were used in different orders when building the lathers for each set and pictures were taken right after building the lathers, as shown in the next section. This methodology was not perfect, but it was fair for studying the variable of water hardness.

Experimental Results

The first experimental set was with L&L Grooming (now Declaration Grooming) unscented shaving soap from November 11, 2017, to November 16, 2017. Lathers built with L&L Grooming and the five test waters are shown below. The author did not notice any differences in person, and upon comparing the photographs, differences between the lathers were still not seen. However, differences were felt during the shaves. Test waters were used in the following order: 0 mg/L, 100 mg/L, 250 mg/L, 500 mg/L, 1000 mg/L, 0 mg/L. In general, when increasing water hardness from 0 mg/L to 1000 mg/L, friction was noticed as increasing and post-shave was noticed as becoming drier to the point that there was even a little irritation with 1000 mg/L, which was surprising given all prior experience with L&L Grooming shaving soap. The decline in lather quality with increasing water hardness was made clear when jumping from 1000 mg/L to 0 mg/L in sequential shaves. The lather with 0 mg/L water produced slickness and post-shave quality that were definitely better than with 1000 mg/L water. Differences were significant enough to notice, but not incredibly so.

(Click on image for full-resolution version)

The second experimental set was with Mitchell's Wool Fat (MWF) shaving soap from December 10, 2017, to December 14, 2017. Lathers built with Mitchell's Wool Fat and the five test waters are shown below. Differences in these lathers were noticed in person and can be observed in the photographs. With increasing water hardness from 0 mg/L to 1000 mg/L, lather building took more time to get going, but the lather quickly built up to become fluffier with larger air cells and less stability, as evidenced by the cleaner look of the lathering bowl due to the collapsing of lather by picture-taking time. More importantly, lather quality differences were felt during the shaves. Test waters were used in the following order: 0 mg/L, 1000 mg/L, 100 mg/L, 500 mg/L, 250 mg/L. In general, when increasing water hardness from 0 mg/L to 1000 mg/L, friction, including stick-slip, was noticed as definitely increasing and post-shave was felt to definitely become drier. Differences in this second experimental set were more readily noticed, as intended, due to sequential shaves with greater differences in water hardness compared to the first set.

(Click on image for full-resolution version)

Advice

Given experimental results detailed here, as well as anecdotal evidence from others, distilled/purified water appears to make the best lather for any given shaving soap or cream, making lather with the best slickness, cushion, and post-shave relative to the soap or cream. Distilled water is recommended as the simplest water option when making lather, especially when distilled water is placed in a bottle with a top that can dispense individual drops of water. If distilled water is unavailable, then another inexpensive, readily available option may be a little citric acid added to one's tap water. Controlled experimentation with citric acid might be performed in the future.

For those who wish to test the effects of water hardness on lather quality, here is my advice:

- Get some inexpensive Epsom salt and distilled water if you don't already have these ingredients.

- Follow the simple recipes above with volume or mass measurements to make the 4000 mg/L hard water stock and whatever test waters with different hardnesses that you'd like to use. The hard water stock and test waters can be made and stored in a variety of short- and long-term containers.

- Experiment with the waters of different hardness with whatever soaps and creams that you'd like to use. Lathering can be done in the same way as you normally would, but with test water instead of your normal water. The key is consistency, keeping everything the same in your experimentation except for the change of water used to build your lather.

References

[1] http://www.cleaninginstitute.org/clean_living/soaps__detergents_chemistry.aspx

[2] https://en.wikipedia.org/wiki/Hard_water

[3] https://en.wikipedia.org/wiki/Water_softening

[4] https://en.wikipedia.org/wiki/Chelation

[5] https://www.badgerandblade.com/forum/threads/soaps-that-work-well-with-hard-water.435802/page-2#post-6924709

[6] https://water.usgs.gov/edu/hardness.html

[7] https://water.usgs.gov/owq/hardness-alkalinity.html

[8] http://www.dwi.gov.uk/consumers/advice-leaflets/hardness_map.pdf

[9] https://en.wikipedia.org/wiki/Purified_water

[10] https://pubchem.ncbi.nlm.nih.gov/compound/24843

[11] https://pubchem.ncbi.nlm.nih.gov/compound/10112

[12] http://www.ciaaw.org/atomic-weights.htm

[13] http://www.ciaaw.org/pubs/TSAW2013_xls.xls

[14] https://www.nist.gov/sites/default/files/documents/2017/04/28/GLP_10_20130424-2.doc

[15] https://www.astm.org/Standards/E1945.htm

[16] https://en.wikipedia.org/wiki/Cup_(unit)

[17] https://www.badgerandblade.com/forum/threads/l-l-grooming-optimization-results-review-photos-details.530210/

[18] https://www.badgerandblade.com/forum/threads/mitchells-wool-fat-mwf-optimization-results-help-solve-the-mystery.533665/

[19] https://www.badgerandblade.com/forum/threads/optimum-lather-table-with-soap-cream-and-water-masses.526020/

[20] https://www.badgerandblade.com/forum/threads/modifying-safety-razor-aggressiveness-efficiency-with-blade-shims-reverse-shims-and-tape-strips.532243/

I am convinced that the softest water is best for building lather, and I know that there are plenty of others who already know this, but as far as I know, I'm the first to document the effects of water hardness with pictures and controlled experimentation to effectively prove what others already know.

I am convinced that the softest water is best for building lather, and I know that there are plenty of others who already know this, but as far as I know, I'm the first to document the effects of water hardness with pictures and controlled experimentation to effectively prove what others already know.

You're right about this making a good classroom exercise. I didn't show the chemical reactions for soap scum, but I'm sure that you would have incorporated them, too. Now, if only we can get traditional shaving on the school curriculum...

You're right about this making a good classroom exercise. I didn't show the chemical reactions for soap scum, but I'm sure that you would have incorporated them, too. Now, if only we can get traditional shaving on the school curriculum...