As I await delivery of a Valet AutoStrop VC1 that will accept a more easily modified SE blade, I decided to attempt to make a modern blade work on one of the later Valet razors.

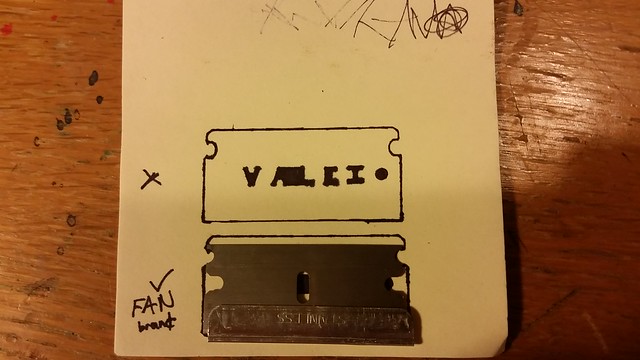

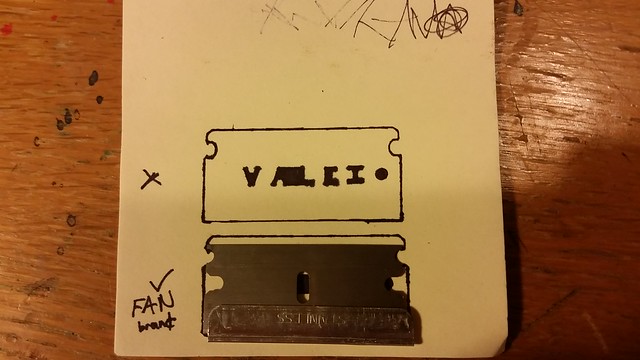

I started by tracing two different vintage blades onto paper. Note that the bottom blade is flipped over from the tracing so you can see the writing on it. In hindsight, I probably could have saved a lot of time by just tracing the cutouts directly onto new SE blades, but I guess I just wasn't in the mood for playing around with exposed edges so much.

I used a pair of pliers, squeezing directly on the folded edge and wiggling slightly, to remove the aluminum spine. Rather than immediately recycling it, I kept it around to protect myself from the exposed edge of the blade being modified. I decided to mod a used (instead of new) GEM stainless, PTFE-coated blade because, well, who knows...

I compared the new blade with the cutouts of the old blades to get a better sense of how much material I'd have to remove. Note that the de-spined GEM blade isn't quite as tall as either the Valet or Fan blades. I also noticed, fitting both old blades into each of the Valet AutoStrops that I have, that the Fan blade seemed to sit more solidly and line up better than the other blade, which I assumed to be original Valet.

Because much of the L portion was already open, I looked at my razors to see which would be easiest to work with (i.e., fewest additional holes). Clockwise from top left: VC2, VC2, VC3, VC4 (with solid bar). Because the two other cutouts on the VC4 were in line with one another, I decided to work with that razor.

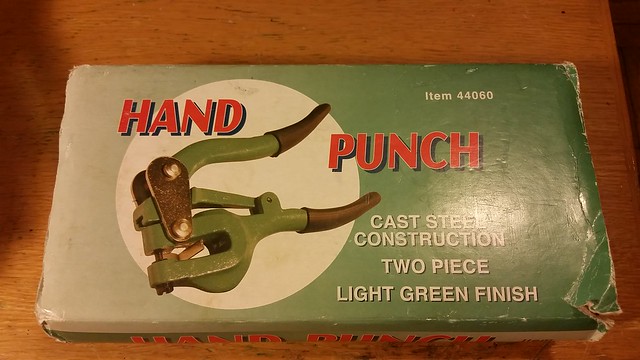

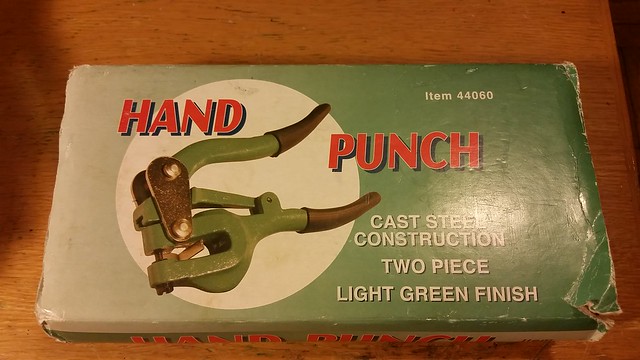

Busting out my trusty hand punch (Harbor Freight item number 44060 is not appearing on their site anymore), I fitted the smallest punch and die, 3/32".

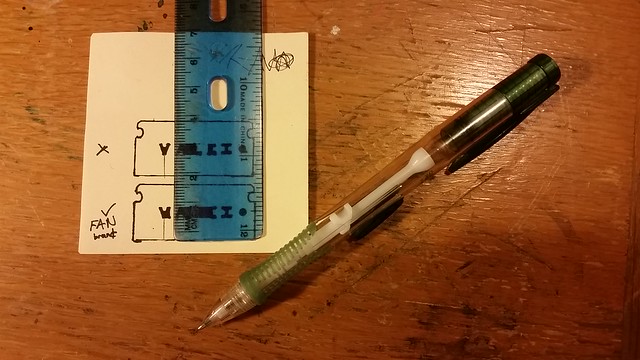

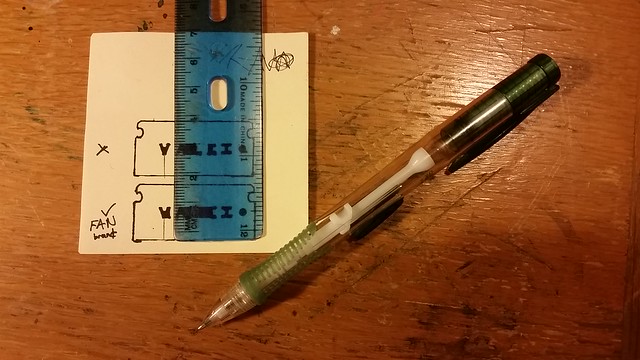

Next I used a ruler and pencil to mark lines and measure where I'd want to punch the holes in the modded blade. Again, I probably should have just traced the cutouts directly from the vintage blades, perhaps by taping the two blades together to protect myself from the sharp edges, but hindsight is 20/20.

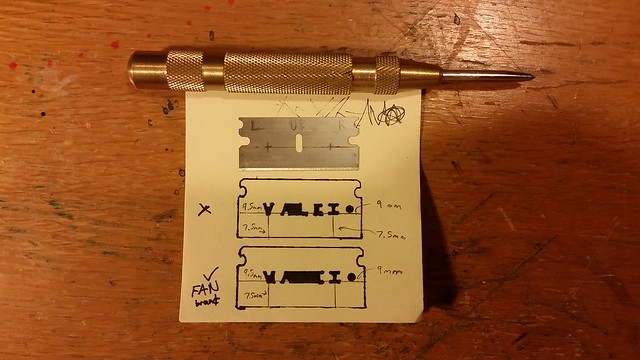

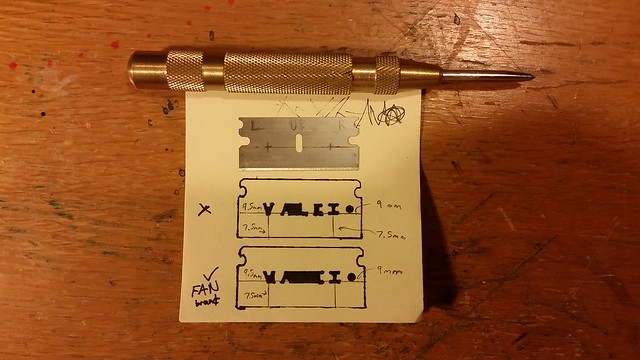

Using my automatic (spring-loaded) center punch (Harbor Freight item 621), I created marks to make it easier to align the hand punch. This is when I realized just how brittle the SE blade steel is, as seen by the cracks coming from the center-punched holes. I contemplated using just the center punch to modify the blade, but figured it wouldn't remove enough material and would more likely snap the blade in the process.

As you can see, the punched holes aren't the cleanest, but they appear to be generally lined up.

Even before closing things up, it appears that the blade is slightly off to the side. When fully installed and engaged, the corner of the blade barely touches the blade stop on the left corner.

So, after all of that work, it was the moment of truth. Being bearded, I washed my neck with Equate Deep Cleansing Skin Cream with Eucalyptus Oil (Walmart's Noxema Original Deep Cleansing Cream knock-off), loaded up my Semogue 620 boar brush with Proraso red cream, and lathered up. What came next.... was a mild but effective 3-pass DFS. The weight and shape of the AutoStrop head was a little weird to get used to at first, so I can certainly see attaining a BBS shave with a little more practice.

I may or may not go through the effort of modding more blades to work with my other later Valet razors, but it was fun to try. With NOS blades and Feathers available, it probably wouldn't be worth it for many people. I have enough other razors that I don't need to rely on the AutoStrops, so it's not like it requires a lot of repeat effort. I also contemplated flattening out the pins (or whatever you want to call them) on one of my razors so that I could simply used a de-spined SE blade, but I'd have to play with ways to align the blade otherwise. At any rate, I hope this has been educational or at least interesting!

I started by tracing two different vintage blades onto paper. Note that the bottom blade is flipped over from the tracing so you can see the writing on it. In hindsight, I probably could have saved a lot of time by just tracing the cutouts directly onto new SE blades, but I guess I just wasn't in the mood for playing around with exposed edges so much.

I used a pair of pliers, squeezing directly on the folded edge and wiggling slightly, to remove the aluminum spine. Rather than immediately recycling it, I kept it around to protect myself from the exposed edge of the blade being modified. I decided to mod a used (instead of new) GEM stainless, PTFE-coated blade because, well, who knows...

I compared the new blade with the cutouts of the old blades to get a better sense of how much material I'd have to remove. Note that the de-spined GEM blade isn't quite as tall as either the Valet or Fan blades. I also noticed, fitting both old blades into each of the Valet AutoStrops that I have, that the Fan blade seemed to sit more solidly and line up better than the other blade, which I assumed to be original Valet.

Because much of the L portion was already open, I looked at my razors to see which would be easiest to work with (i.e., fewest additional holes). Clockwise from top left: VC2, VC2, VC3, VC4 (with solid bar). Because the two other cutouts on the VC4 were in line with one another, I decided to work with that razor.

Busting out my trusty hand punch (Harbor Freight item number 44060 is not appearing on their site anymore), I fitted the smallest punch and die, 3/32".

Next I used a ruler and pencil to mark lines and measure where I'd want to punch the holes in the modded blade. Again, I probably should have just traced the cutouts directly from the vintage blades, perhaps by taping the two blades together to protect myself from the sharp edges, but hindsight is 20/20.

Using my automatic (spring-loaded) center punch (Harbor Freight item 621), I created marks to make it easier to align the hand punch. This is when I realized just how brittle the SE blade steel is, as seen by the cracks coming from the center-punched holes. I contemplated using just the center punch to modify the blade, but figured it wouldn't remove enough material and would more likely snap the blade in the process.

As you can see, the punched holes aren't the cleanest, but they appear to be generally lined up.

Even before closing things up, it appears that the blade is slightly off to the side. When fully installed and engaged, the corner of the blade barely touches the blade stop on the left corner.

So, after all of that work, it was the moment of truth. Being bearded, I washed my neck with Equate Deep Cleansing Skin Cream with Eucalyptus Oil (Walmart's Noxema Original Deep Cleansing Cream knock-off), loaded up my Semogue 620 boar brush with Proraso red cream, and lathered up. What came next.... was a mild but effective 3-pass DFS. The weight and shape of the AutoStrop head was a little weird to get used to at first, so I can certainly see attaining a BBS shave with a little more practice.

I may or may not go through the effort of modding more blades to work with my other later Valet razors, but it was fun to try. With NOS blades and Feathers available, it probably wouldn't be worth it for many people. I have enough other razors that I don't need to rely on the AutoStrops, so it's not like it requires a lot of repeat effort. I also contemplated flattening out the pins (or whatever you want to call them) on one of my razors so that I could simply used a de-spined SE blade, but I'd have to play with ways to align the blade otherwise. At any rate, I hope this has been educational or at least interesting!

Last edited: