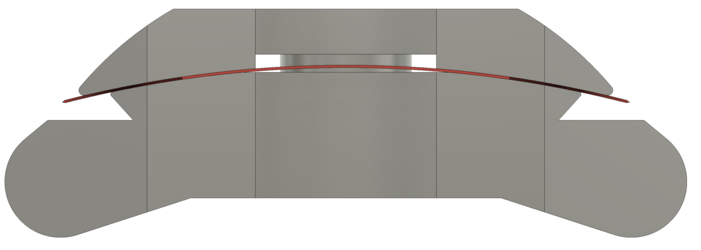

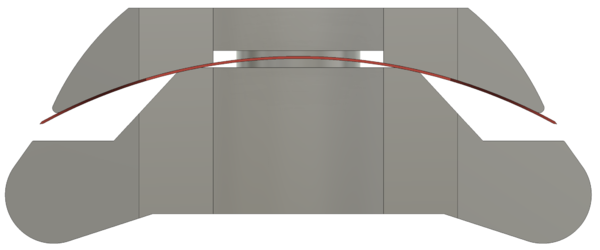

The point was that the razor has a unique head design that allows for different rigidity depending on the direction you flex the blade.I don't understand how there is a claim that the Blackbird is rigid at all. There are a lot of people who like the razor so you don't need a razor to be rigid to be good... But that razor seems the antithesis of rigid.

There is no claim that this is a rigid blade clamping at all.

You can design a razor with a floating blade, like the OREN SE.

Double thumbs up for a such a brilliant project.

Double thumbs up for a such a brilliant project.