Hi guys,

Even though I’ve been here on the forum for a while now, this is my very first post.

I’m glad to join the B&B community!

I switched to wet shaving around a year ago and like many of you, got a bit geeky about it too. Over the past months I read many topics on various DE razors and got especially interested in parameters and how they influence razors’ performance and feel, as I simply find it very interesting.

Even though we can find great amount of information on the matter on the forum (e.g. fantastic Safety Razor Parameters: Illustrated and Defined thread), there are still many questions unanswered to me.

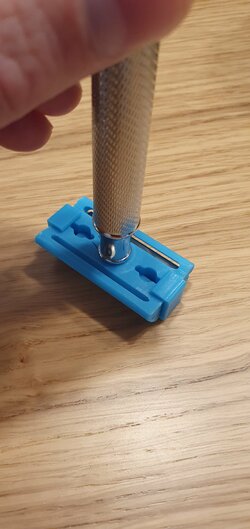

Lately I’ve been on sick leave from work for almost two months now so had a lot of spare time and one day an idea came to my mind. The idea is to test various parameters of DE razors and understand how they influence shaving experience. I’m a mechanical engineer with CAD experience, so design is not a problem for me, and on top of that I already have a 3D printer at home which I can use for printing razors.

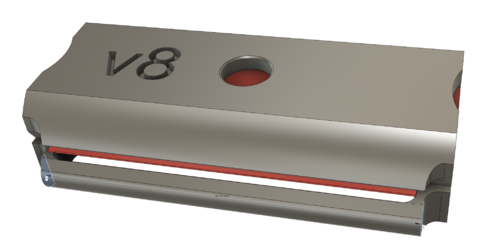

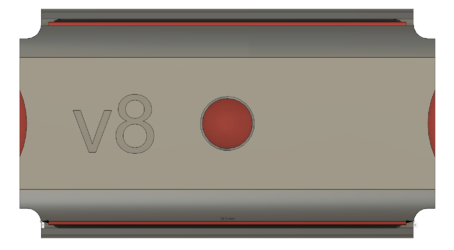

To start with, I created a design which allows me to change the following parameters independently one by one, without influencing other ones:

- Blade gap

- Blade exposure

- Neutral blade angle

- Guard span

- Cap span

- Clamp distance

- Guard/shave plane distance (I will elaborate on it in a separated thread)

After struggling with some technicalities and printing few prototypes, I finally managed to create a razor which can be used as a baseline:

- Blade gap: 0.65 mm

- Blade exposure: 0.00 mm

- Neutral blade angle: 30 deg.

- Guard span: 2.00 mm

- Cap span: 2.00 mm

- Clamp distance: 2.03 mm

- Guard/shave plane distance: 0.1 mm

I didn’t expect much from a 3D printed razor, but after shaving with it yesterday I was amazed how decent it was, even though I am a fan of high efficiency razors with strong blade feel (my daily razors are Muhle R41 and Rockwell 6C R6). If I needed to compare, I would say it was as mild as Muhle R89 but definitely more efficient.

I will be rating razors in scale of 1-5 in the following categories:

- Efficiency (higher is better)

- Blade feel (higher is better) – I enjoy blade feel, so higher is better to me

- Smoothness (higher is better)

- Aggressiveness (lower is better)

- Alum response (lower is better)

- Clogging (lower is better)

- 1 day razor bumps (lower is better)

- Overall score (higher is better)

Since I shave every 2-3 days it will take me some months to run the test, but I hope at the end of it we can get some added value and better understanding of DE razors parameters.

I would also appreciate your help along the way - it would be nice to collect questions related to parameters which then can be investigated and hopefully answered.

Thanks,

Dawid

Even though I’ve been here on the forum for a while now, this is my very first post.

I’m glad to join the B&B community!

I switched to wet shaving around a year ago and like many of you, got a bit geeky about it too. Over the past months I read many topics on various DE razors and got especially interested in parameters and how they influence razors’ performance and feel, as I simply find it very interesting.

Even though we can find great amount of information on the matter on the forum (e.g. fantastic Safety Razor Parameters: Illustrated and Defined thread), there are still many questions unanswered to me.

Lately I’ve been on sick leave from work for almost two months now so had a lot of spare time and one day an idea came to my mind. The idea is to test various parameters of DE razors and understand how they influence shaving experience. I’m a mechanical engineer with CAD experience, so design is not a problem for me, and on top of that I already have a 3D printer at home which I can use for printing razors.

To start with, I created a design which allows me to change the following parameters independently one by one, without influencing other ones:

- Blade gap

- Blade exposure

- Neutral blade angle

- Guard span

- Cap span

- Clamp distance

- Guard/shave plane distance (I will elaborate on it in a separated thread)

After struggling with some technicalities and printing few prototypes, I finally managed to create a razor which can be used as a baseline:

- Blade gap: 0.65 mm

- Blade exposure: 0.00 mm

- Neutral blade angle: 30 deg.

- Guard span: 2.00 mm

- Cap span: 2.00 mm

- Clamp distance: 2.03 mm

- Guard/shave plane distance: 0.1 mm

I didn’t expect much from a 3D printed razor, but after shaving with it yesterday I was amazed how decent it was, even though I am a fan of high efficiency razors with strong blade feel (my daily razors are Muhle R41 and Rockwell 6C R6). If I needed to compare, I would say it was as mild as Muhle R89 but definitely more efficient.

I will be rating razors in scale of 1-5 in the following categories:

- Efficiency (higher is better)

- Blade feel (higher is better) – I enjoy blade feel, so higher is better to me

- Smoothness (higher is better)

- Aggressiveness (lower is better)

- Alum response (lower is better)

- Clogging (lower is better)

- 1 day razor bumps (lower is better)

- Overall score (higher is better)

Since I shave every 2-3 days it will take me some months to run the test, but I hope at the end of it we can get some added value and better understanding of DE razors parameters.

I would also appreciate your help along the way - it would be nice to collect questions related to parameters which then can be investigated and hopefully answered.

Thanks,

Dawid