Slash McCoy

I freehand dog rockets

Pretty sure I have never seen any GD with a 19.5° bevel angle. Nearly all are considerably less than 19 degrees and as I recall most 208's were just over 18°. The only thing I have personally seen being seriously sold as a razor with a bevel angle of 19.5° was the ZY430 Pro.I have measured the bevel angle at mid edge length of a few of my SR's. They are:

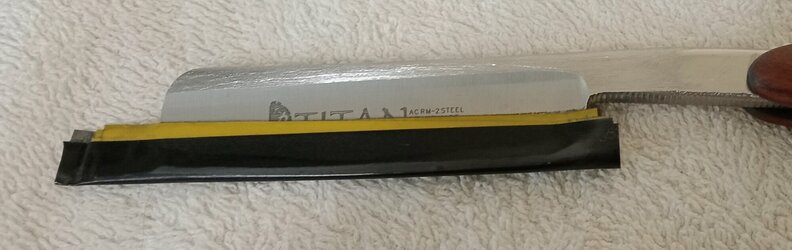

S.K. Colling Custom = 16.5°Ralf Aust 6/8 = 16.3°*Gold Dollar W59 = 15.8° & 17.5° (modified)*Gold Dollar 208 = 19.5°Revisor 6-0035 = 16.9°G. Butler Shakespeare = 17.4°Puma 1⅝ = 16.8°Cadman Bengall 5/8 = 16.1°, 17.1°, 17.5° & 17.4°Cadman Bengall 6/8 = 16.0°, 16.9° 15.7°*Titan T.H.60 = 18.8° & 19.6°*Titan T.H.63 = 18.8°*Titan T.H.64 = 19.1°*Titan T.H.70 = 18.6°, 19.0°, 18.0°, 19.7°, 18.4°, 19.7° & 18.6°

Obviously the Asian (*) market is preferring more obtuse bevel angles by about 2°. I'm not sure if @Slash McCoy has some figures for other Gold Dollar models.

All of my SR's have been honed up and are maintained to my high standard of shave-ready. I have found that the Asian made SR's shave just as well as the European made SR's. The Asian made require just a little more pressure tangential to the skin to slice through the whiskers. This is noticed particularly in the fool's pass, my standard edge test that is performed daily. They all shave comfortably and just as closely. I would say that bevel angle is more important if the edge is not as keen as it should be.