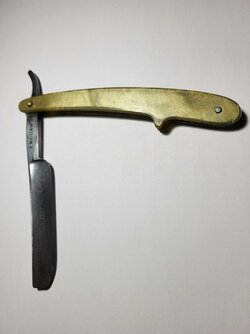

I found this straight while cleaning my Dad's house out.

I did a quick Google search and not much comes up.

I was wanting to know a little bit about it.

It has a chip in the end of the Blade. Is this something that can be fixed or made usable?

I thought about taking a bench grinder or file and trying to just curve off the pointed edges.

Has anyone did this before. Or if you have other suggestions how to make it shave ready let me know.

Thanks in Advance!

I did a quick Google search and not much comes up.

I was wanting to know a little bit about it.

It has a chip in the end of the Blade. Is this something that can be fixed or made usable?

I thought about taking a bench grinder or file and trying to just curve off the pointed edges.

Has anyone did this before. Or if you have other suggestions how to make it shave ready let me know.

Thanks in Advance!