I've got some Gillette Techs and always get smooth, comfortable shaves with them. Two have ball end handles and rectangular baseplate reliefs; the third has a fat handle and triangular reliefs and was my grandfather's.

Among my other razors I have a red tip Super Speed which always gives me great shaves. I appreciate the slightly more aggressive shave I get from the red tip and have decided to experiment with shimming my fat handled Tech to adjust its blade gap upward slightly.

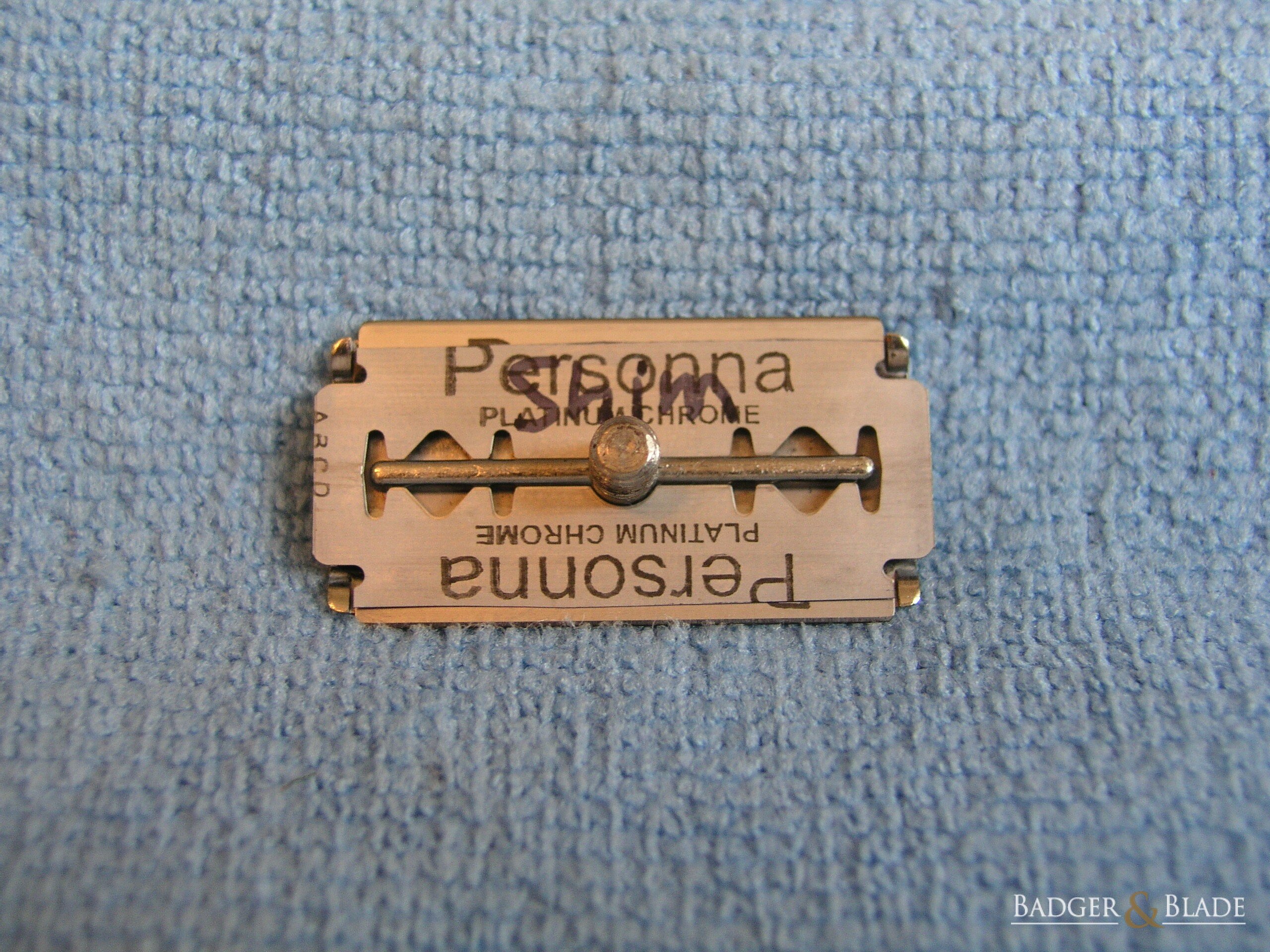

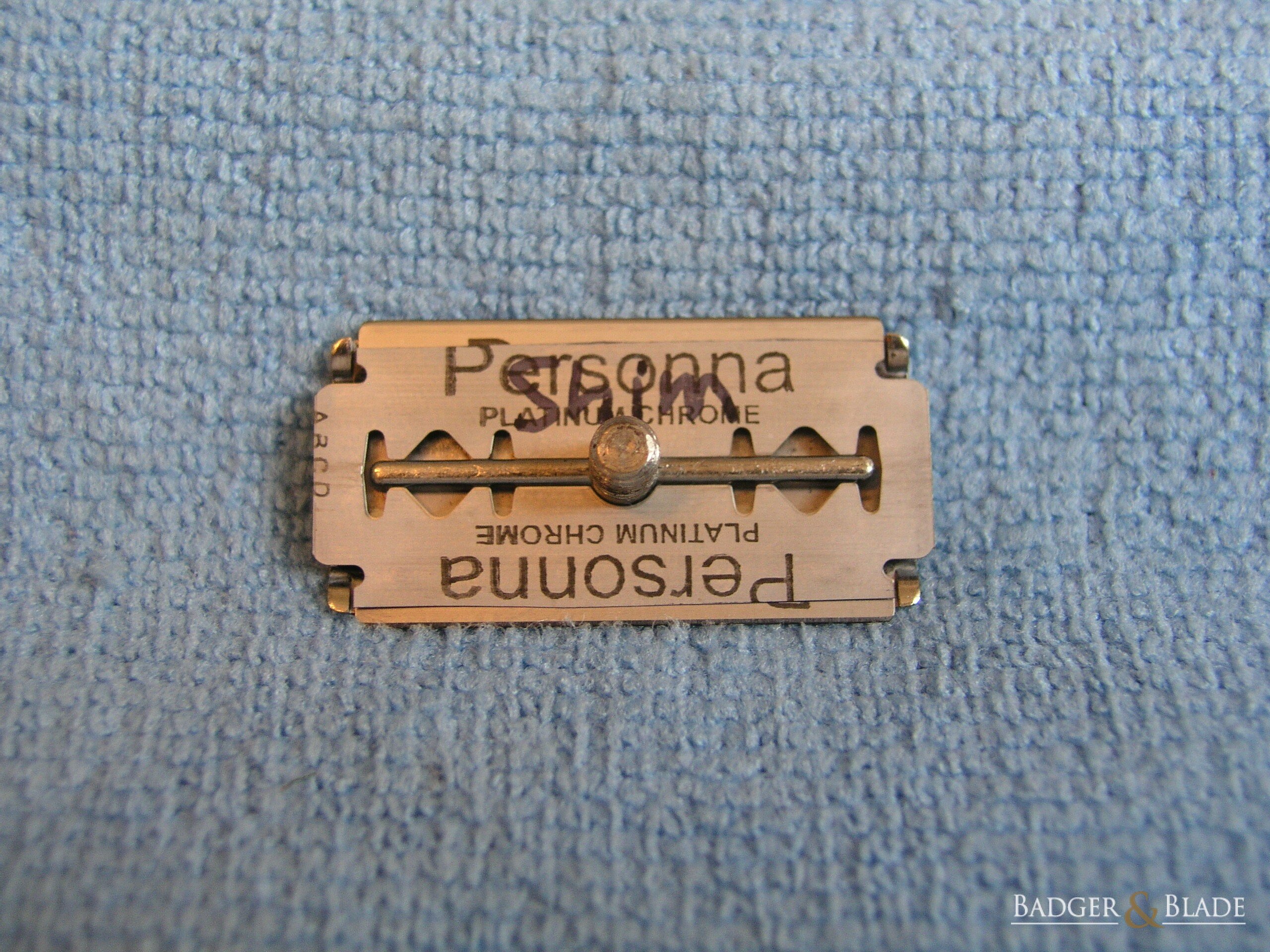

For my shim I decided to trim the cutting edges off of a used DE blade. First I marked it with a Sharpy:

I then used some old scissors and trimmed to the inside of each marked line. This picture shows the blade setting on the inverted razor cap:

A few things to note at this point:

- You probably don't want to use your best scissors for this.

- The resulting shim will probably end up a little warped.

- You'll end up with two twisted very sharp slivers of metal for offal. Be very careful how you handle these. Be sure to dispose of them in a proper blade bank or similar sharps container.

Here's how the ship looks laying on top of a new blade:

You'll note that my trim job was far from perfect. The shim's mission is merely to space the blade up from the baseplate a little to increase the gap to the safety bar. Note well that this is the order in which the shim and blade should be stacked. The blade should be immediately under the cap with the shim between it and the base plate.

I'll shave with it tomorrow morning and see how it does. Assuming all goes well I'll probably branch out to try it in some of my other DE razors.

Here are my attempts at gap pictures before

View attachment 96689

and after

View attachment 96690

- Chris

Among my other razors I have a red tip Super Speed which always gives me great shaves. I appreciate the slightly more aggressive shave I get from the red tip and have decided to experiment with shimming my fat handled Tech to adjust its blade gap upward slightly.

For my shim I decided to trim the cutting edges off of a used DE blade. First I marked it with a Sharpy:

I then used some old scissors and trimmed to the inside of each marked line. This picture shows the blade setting on the inverted razor cap:

A few things to note at this point:

- You probably don't want to use your best scissors for this.

- The resulting shim will probably end up a little warped.

- You'll end up with two twisted very sharp slivers of metal for offal. Be very careful how you handle these. Be sure to dispose of them in a proper blade bank or similar sharps container.

Here's how the ship looks laying on top of a new blade:

You'll note that my trim job was far from perfect. The shim's mission is merely to space the blade up from the baseplate a little to increase the gap to the safety bar. Note well that this is the order in which the shim and blade should be stacked. The blade should be immediately under the cap with the shim between it and the base plate.

I'll shave with it tomorrow morning and see how it does. Assuming all goes well I'll probably branch out to try it in some of my other DE razors.

Here are my attempts at gap pictures before

View attachment 96689

and after

View attachment 96690

- Chris

Last edited by a moderator:

) will cause any clogging

) will cause any clogging