New cotton and a lovely piece of steer hide in the plain vanilla configuration.

Strop Acquisition Thread

- Thread starter rbscebu

- Start date

GeronimoWSB

Multilingual Beer

My nearly 10 year old Fast Bridle with cotton next to my new Russian style with hemp and handles both Tony Millers. . Can't wait to try it. I still have my practice strop as well lol.

Restored an old strop using the wiki, so thanks to @Luc for writing that guide all those years ago.

The linen was far beyond saving, but the leather feels amazing.

The linen was far beyond saving, but the leather feels amazing.

Tony Miller Horsehide

I also made a cover for it this weekend. The flap holding it up needs some improvement but overall I’m happy with it

I also made a cover for it this weekend. The flap holding it up needs some improvement but overall I’m happy with it

Can you please send me his contact address?Just in today. Made in Poland by Dawid Saczuk. Met him on FB and he was a pleasure to deal with.View attachment 1787961View attachment 1787962View attachment 1787963View attachment 1787964

Can you please send me his contact address?

PM sent

First, I just put in an order with Tony Miller for a 3" Bridle/new cotton strop, plus a 3" cotton only strop. I love that new tight/light/fast cotton he has. He has a doldrums sale going.

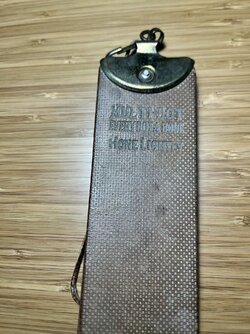

Second, I picked up this Moler 328 for the history rack:

I grew up seeing ads for Moler Barber College every time I went into the Loop. This strop is lightly worn, with no nicks, cuts or other significant damage. The grip area has the only noticeable surface wear.

It is substantial, about 3/16" thick down to the grip area where it is a full 1/4". The 'DEEP-CUT' diamond pattern greatly reduces the stiffness. I wouldn't call it extra soft.

I note that the word "RUSSIA" appears as an adjective, but not defining the origin of the "GENUINE IMPORTED LEATHER".

There are still Moler Barber Colleges out there, at least in the Bay Area and North Dakota. Apparently gone from Chicago, where they originated in 1893 according to my internet browsing.

Second, I picked up this Moler 328 for the history rack:

I grew up seeing ads for Moler Barber College every time I went into the Loop. This strop is lightly worn, with no nicks, cuts or other significant damage. The grip area has the only noticeable surface wear.

It is substantial, about 3/16" thick down to the grip area where it is a full 1/4". The 'DEEP-CUT' diamond pattern greatly reduces the stiffness. I wouldn't call it extra soft.

I note that the word "RUSSIA" appears as an adjective, but not defining the origin of the "GENUINE IMPORTED LEATHER".

There are still Moler Barber Colleges out there, at least in the Bay Area and North Dakota. Apparently gone from Chicago, where they originated in 1893 according to my internet browsing.

The term Russia is a Birch bark tanning process, though some were imported from Russia. The special process could take as long as 11 month of tanning. Many “Russia” tanned strop backs were cut in diamond or straight pattern or rib molded, likely for more flexibility of thicker strops.

I have a vintage “Certyfied” Russian tanned and Diamond cut back, about a ¼ inch thick, that I restored and re-hydrated years ago. It is my shop strop that stays well hydrated and sees every razor that comes through my shop.

I often finish strop on the diamond cut side for a great finish on a freshly honed razor.

Nice find

I have a vintage “Certyfied” Russian tanned and Diamond cut back, about a ¼ inch thick, that I restored and re-hydrated years ago. It is my shop strop that stays well hydrated and sees every razor that comes through my shop.

I often finish strop on the diamond cut side for a great finish on a freshly honed razor.

Nice find

Brad, I have noted also that many of the "Russia" / "Russian" tanned strops had the cuts or ribbed corrugations cut or pressed into the skin or grain side rather than the reverse, flesh side. On the Illinois Russian strops they seem to press in the ridges which would create flexibility due to the thin areas but also the compression would increase the hardness or temper of the surface and tame the roughness of the flesh side while staying flexible.The term Russia is a Birch bark tanning process, though some were imported from Russia. The special process could take as long as 11 month of tanning. Many “Russia” tanned strop backs were cut in diamond or straight pattern or rib molded, likely for more flexibility of thicker strops.

I have a vintage “Certyfied” Russian tanned and Diamond cut back, about a ¼ inch thick, that I restored and re-hydrated years ago. It is my shop strop that stays well hydrated and sees every razor that comes through my shop.

I often finish strop on the diamond cut side for a great finish on a freshly honed razor.

Nice find

Brad, I have noted also that many of the "Russia" / "Russian" tanned strops had the cuts or ribbed corrugations cut or pressed into the skin or grain side rather than the reverse, flesh side. On the Illinois Russian strops they seem to press in the ridges which would create flexibility due to the thin areas but also the compression would increase the hardness or temper of the surface and tame the roughness of the flesh side while staying flexible.

So, on Russian strops where they make a big deal of the imported Russian leather, I always assumed that the main selling point was thick-butted Russian horses. Russia's climate and Darwinian selection creating the thick horse butts, I presume.

I am going to go sort through my vintage strop rack and classify/categorize all the Russkies.

Thickness, backside treatment, flesh v smooth, cordovan-ness, and of course the amount and content of the often-copious advertising copy printed or embossed on the strop. Maybe there is already an appropriate thread to record my results and solicit other's.

I just received this beauty in the mail. It's a Duke City short strop (17" belt) and I'm very impressed at the quality of materials used and the high level of craftsmanship for such a low price.

It's a beautiful dark blue leather and it has a synthetic and a natural cotton belt.

It's a beautiful dark blue leather and it has a synthetic and a natural cotton belt.

My 3" Tony Miller Heirloom Old No.2 bridle leather and new cotton arrived a few days back. I also got a stand alone cotton component, for use with my vintage strops (and probably my Kanayama Llama 30000 too).

I enjoy the bridle leather's draw, a distinctly different sensation from my Tony Miller horse and steer strops. After tonight's use, I predict it will be in heavy rotation for a while.

But the new cotton? It is an unexpected love affair. I love his older linen and his new hemp, but oh you kid!

I'm infatuated with the new cotton draw (zippy!!), which is uniquely smooth and fast among my many fabric components, new and vintage.

Tony Miller 3" Bridle Leather

My new strop from @Tony Miller has just arrived. This strop was purchased as a birthday present to myself, however I just might start using it before that day. I somehow doubt that I will be able to resist the temptation to use it for the next four weeks.

This three inch Artisan European Bridle Leather With two & three quarter inch flax linen strop is a beauty to behold. Also it is somewhat larger than my Invisible Edge Strop.

I am really excited to finally own a @Tony Miller strop and cant wait to use it.

timwcic

"Look what I found"

A trio of strops that have been lying on my workbench way to long. The Illinois and Merit will be wall hangers but the Deep Cut will be put into service. Has the very fast, ice like draw that typically to vintage leather. The linen seconds aren’t to shabby either

I like the finish off a clean Diamond Cut Russian strop, a nice clean thick one is my shop strop. I strop on the diamonds for light finish laps.

Nice collection, the Russian linen looks interesting.

Nice collection, the Russian linen looks interesting.

A trio of strops that have been lying on my workbench way to long. The Illinois and Merit will be wall hangers but the Deep Cut will be put into service. Has the very fast, ice like draw that typically to vintage leather. The linen seconds aren’t to shabby either

View attachment 1906511View attachment 1906512View attachment 1906514View attachment 1906515View attachment 1906516View attachment 1906517

I was surprised and pleased to see another Deep-cut Diamond strop right after I bumped into mine (post 287). I suppose E.M. Mfg. Co. (Certifyd) was the actual maker. The 323 strop number was preserved over to the Moler promotional version I own.

Given the various seemingly random numbers on my vintage strops, I suppose that strop 'model' numbering was primarily driven by marketing ideas that are now lost in the mists.

Maybe @Tony Miller will start selling "Lucky No.7" or "Prime No.1" strops.

Also, Kanayama Llamas proved that more zeros were better zeros. I'll probably never own a strop higher than 30000.

Well, speaking of random. When I made my first strops 19 or so years ago all I had were simple horse and steerhead stamps (now used only on my Plain strops) and a set of numbers. The number "1" just looked so skinny on a strop I decided only my test samples were the "1" strops and started using a "2" which had some width to it and just looked more pleasing for my production strops to sell. Hence today's "Old No. 2" markings on my strops LOLGiven the various seemingly random numbers on my vintage strops, I suppose that strop 'model' numbering was primarily driven by marketing ideas that are now lost in the mists.

Maybe @Tony Miller will start selling "Lucky No.7" or "Prime No.1" strops.

Two "new" strops from @Tony Miller.

1. Tony made a firehose strop for me using new 2.5-inch-wide linen firehose I sourced on eBay. I went with black latigo leather caps to contrast the linen. The strop is 23.5 inch long from the top of the top leather cap to the bottom of the bottom cap to match the 600 mm length of my Kanayama strop. The linen firehose is tough and coarser than traditional linen flax webbing. I washed the firehose four times in the washing machine on warm and then ironed it and rolled it with a glass jar many times. The material is definitely softer than when it arrived. I hope the material continues to soften up.

2. Tony replaced the 3-inch-wide horsehide leather and cotton cloth components on the first plain vanilla strop I bought from him in October 2020 with 2.75-inch-wide premium steerhide and linen flax. The steerhide initially felt tough after mostly stropping on roughout horsehide. After spending a few days rubbing the steerhide with my clean palm, the leather is beginning to soften up and develop a comfortable, softer draw.

Really looking forward to using both strops. Tony does great work!

Both strops hanging on the bed frame for display.

The firehose after being washed a few times.

And then after being ironed.

1. Tony made a firehose strop for me using new 2.5-inch-wide linen firehose I sourced on eBay. I went with black latigo leather caps to contrast the linen. The strop is 23.5 inch long from the top of the top leather cap to the bottom of the bottom cap to match the 600 mm length of my Kanayama strop. The linen firehose is tough and coarser than traditional linen flax webbing. I washed the firehose four times in the washing machine on warm and then ironed it and rolled it with a glass jar many times. The material is definitely softer than when it arrived. I hope the material continues to soften up.

2. Tony replaced the 3-inch-wide horsehide leather and cotton cloth components on the first plain vanilla strop I bought from him in October 2020 with 2.75-inch-wide premium steerhide and linen flax. The steerhide initially felt tough after mostly stropping on roughout horsehide. After spending a few days rubbing the steerhide with my clean palm, the leather is beginning to soften up and develop a comfortable, softer draw.

Really looking forward to using both strops. Tony does great work!

Both strops hanging on the bed frame for display.

The firehose after being washed a few times.

And then after being ironed.

Last edited:

Inherited another grandpa strop recently - this one is quite thick, and the primary strop is still in pretty good shape. The surface is clearly blemished, but it's still firm, supple, uncut and not cracked. It feels a little dirty, maybe a bit oily, but not too bad at all.

The secondary strop is a 'dot' strop, and cracked on one side (the backside of the 'dot' strop looks identical to the front, but unused and uncracked).

Are there any best practices for cleaning up an older strop? I followed a BnB guide written long ago for another strop (basically just a saddle-soap cleaning). I've also seen recommendations for light, fine sanding around 600 grit. I was curious if anyone had any more recent thoughts or tips? I see @Tony Miller sometimes comments, and I wasn't sure if there were any other makers/professionals around. It would be great to either put grandpas back into use, or know what to look for if it's beyond saving. Thanks in advance the amount of knowledge and help is really wonderful!

The secondary strop is a 'dot' strop, and cracked on one side (the backside of the 'dot' strop looks identical to the front, but unused and uncracked).

Are there any best practices for cleaning up an older strop? I followed a BnB guide written long ago for another strop (basically just a saddle-soap cleaning). I've also seen recommendations for light, fine sanding around 600 grit. I was curious if anyone had any more recent thoughts or tips? I see @Tony Miller sometimes comments, and I wasn't sure if there were any other makers/professionals around. It would be great to either put grandpas back into use, or know what to look for if it's beyond saving. Thanks in advance the amount of knowledge and help is really wonderful!

Attachments

Last edited:

Made a little bench strop today. Put a strip of packing foam like the chunk shown inside and stitched the ends with waxed thread. Applied a bit of white paste from Etsy on the opposite side.

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 10

- Views

- 703

- Replies

- 2

- Views

- 986