well with the wife laid off and the shop deadly slow I have less than zero hobby funds. Selling off all of my stock and keeping what i use daily. Really want to give a straight a go but with no funds it makes it hard. I have an old razor I got a bit ago so I figured instead of hoping a usable one would fall from the sky I would at least make the one I cant use look displayable. I love restoring DE's and find satisfaction in bringing to live what others thought was dead. Truly my AD. It has a hairline crack right at the heel that gives some flex to point of not being able to become shave ready. anyway here is my start. This is my first shot at a restore on a straight.

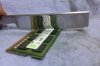

The first pic's are how she was this morning when I started on it. It had only been cleaned and not much more. the second pic's are after about an hour or so with 240 the rust is gone and other than that killing blow crack it looks good.

The first pic's are how she was this morning when I started on it. It had only been cleaned and not much more. the second pic's are after about an hour or so with 240 the rust is gone and other than that killing blow crack it looks good.