Thanks. Will check them out.I've had really good service from Voyageur Soap & Candle. Quality product and sizes from "I just want to try some" to "I need a boxcar full."

O.H.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Soap Makers And Users Group (SMAUG)

- Thread starter Old Hippie

- Start date

Soapcalc is good but to do dual lye soaps you have to have it calculate it twice one for each lye type. Lyecalc on the other hand will calculate it for you ask at onceThat would be really nice.

I can imagine myself giving a bunch of shaving soap away for Christmas this year. Maybe we can start with a smaller quantity just to experiment. I don't know how all these measurements scale. I have seen Soapcalc being used on some websites.

It acts as a transport agent for water (and fats) to bring it into your skin. And to hold more water in your lather. The leftover from saponification is not enough.Wondering why you need to add extra glycerin, isn't that produced already as a by-product during saponification?

GlideWhat benefit does the Bentonite Clay provide?

Definitely. That’s how it works. In the end only the fatty acid deviation matters.acid content like shea butter in place of some of the stearic acid? I already have some shea butter here.

I did that too on my second batch. I substituted some stearic acid by mango and cacao butter. Worked fine

Yes glycerin is produced during the process. I add some extra for goodness sake. It is certainly not a must, but adds a bit extra post shave feeling.Wondering why you need to add extra glycerin, isn't that produced already as a by-product during saponification?

What benefit does the Bentonite Clay provide?

Can I use a natural fat with a lot of stearic acid content like shea butter in place of some of the stearic acid? I already have some shea butter here.

Bentonite Clay in shave soap is a bit of a controversial ingredient. Some think that is dulls the blades, but I have not found that to be true. I do think that it does add a bit of slickness to the soap though. I usually put some sort of clay in almost all my soaps, bath and shave soap. Now there are also many soap makers that thinks that bentonite clay is what makes a shave soap so they just add that to their normal bath soap recipe and call it good. This will not work.

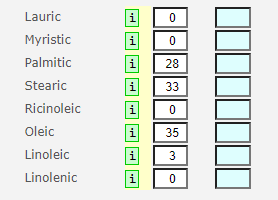

As far as using butters in shave soap. Absolutely they will do great. they contain a fair amount of stearic acid in themselves and are used extensively in shave soap. If you look below. This is an example of shea butter's fatty acids and you can see that it contains a good bit of stearic acid. Stearic acid and palmitic acid are the two acids most KEY to a good shave soap. You want a high percentage of these. They will generate nice stable lather. You can look at soapcalc or any other calculator and just add one oil/fat and see what the fatty acid composition for that fat/oil is.

Attachments

You can use Lard in smaller amounts, but not in large. It does not have that great of a stearic/palmitic acid balance. Tallow is better for this.I dug out the recipe I use. It was developed by Lee Bussey (Silver Fox).

204.1 g stearic acid

113.4 g coconut oil

90.7 g beef tallow

49.9 g glycerin

22.7 g lanolin

22.7 g shea butter

17 g fragrance oil

201.8 g distilled water

99.4 g potassium hydroxide (KOH)

I generally apply a little rounding to the amounts. While for some things micrograms matter, in this case a couple tenths one way or another to make things simple doesn't seem to matter much.

I've used different scents; red cedar and peppermint mostly. Enough of each that I'm branching out a bit. I have some grapefruit, also rose, lavender, eucalyptus, lemon, orange...that we use for other things as well. Probably I won't be using rose as I'm really not a huge rose fan but lately I've been grooving on lavender. I tend to figure that if it'd smell good in cookies it'd make some cool soap. Bacon, coffee and fresh toasty biscuits? Maybe there are some limits.

As I've said I tend to like to stick with what works, but at the same time I'm all about learning things so that occasionally takes me out of my box. I've been looking at Carrie Seibert's formulas (she was a founder of Soap Commander) and there are a couple that look interesting. Probably once I've got the next batch "in the can" I'll crank up one of hers just to see how it goes.

Coconut oil, glycerin, fragrance and distilled water I buy in town. Beef tallow we render ourselves (also lard but probably that would make skanky soap). That leaves stearic, lanolin, shea, and KOH that have to come from Voyageur.

This formula works OK in moderately hard water. It also has good residual slickness.

O.H.

There is actually another source for stearic acid that can be an alternative that I have not used yet, but have seen been used and that is fully hydrogenated soybean oil. This is pretty much all stearic acid and makes for a good shave soap. This can be bought from candle making places as candle wax. You have to make sure though that it is not a blend and just pure fully hydrogenated soybean wax. It might be easier to get hold of and I so see that some of the soap calculators have fully hydrogenated soybean wax listed so you can formulate your soap.

That works pretty good. May you‘ll find it as soywax.fully hydrogenated soybean oil

Yep and GW 415 is a pure soy wax. Also if you do not want to use stearic acid, which is mostly refined from palm oil, you can use soy wax.That works pretty good. May you‘ll find it as soywax.

DIY Cooking Shaving soap for beginners

Dear wet shavers,

We have a holistic hobby and soap making can be a funny part of it (for some, soap making is a full hobby). But how to cook a good shaving soap. Some said, that cooking shaving soap is the Olympus in soap cooking. I don’t think so. I found it to be very easy (actually, I mucked my first bath soap attempt )

)

But for the beginning we should jump into some theory (sorry, I know you want to play with chemicals, but you should know what you’re doing and why)

What is soap?

Simply said, it’s a salt. Yes, a salt. Made from an acid (fatty acid) and a metal ion (sodium and/or potassium in our case. (We recall from 9 th grade chemistry )

)

The sodium salts of fatty acids are called “curd soap” (solid)

And the potassium salts are called “soft soap” (liquid)

Fatty acids are long hydrocarbon chains (from 6-22 carbon atoms) with a carboxyl group (COOH) at the end. E.g., a well-known carboxylic acid is vinegar (acetic acid) (with two carbon atoms in its chain).

Fat

Fat is the triple esther of glycerol (alcohol) and fatty acids. (there are more types of fat and lipids, but we’re looking for the triglycerides)

The differences in fats are the distribution of the bounded fatty acid. Every plant or animal fat have their own distribution.

This distribution of fatty acids makes later the lather properties.

Here is a little overview of typical fats/oils and their fatty acids

Table Fatty acid composition of selected oils and fats.xls (fediol.eu)

Deutsche Gesellschaft für Fettwissenschaft (dgfett.de)

Saponification

Saponification is a process of converting esters (fat) into soaps (salt of the fatty acid) and alcohols (glycerol) by the action of aqueous alkali (for example, aqueous sodium/potassium hydroxide solutions).

If you are interested in this topics (you should, a little bit, because soap making is organic chemistry (ester hydrolysis). Read some of the linked articles, pls.

Now the fun part, splash about chemicals.

The Soapmaking

Before we start:

We want to work with chemicals. So occupational safety is an issue. Lye is extremely corrosive for your skin and even worth for your eyes!

WEAR SAFTYGOGGLES AND GLOVES WHILE HANDLING LYE (and solid NaOH or KOH)!!

Keep Food and beverage away from your working space, don’t put chemicals (Lye) in beverage containers.

If lye gets into your eyes, wash with plenty of water (15 min !!!) and seek medical advice.

What do we need.

As a starting point I’ll begin with my last recipe for explanation. (This is a larger batch [+/- 3kg], just adjust the amounts, if it’s to much)

As we are into science, I use the metric system (grams, °C)

Saponified with 5 % superfat (overfat) and dual lye (55 % KOH : 45% NaOH)

That’s how it’s calculated. Every percentage figures in soap recipes are related to the amount of total fat weight. So if I refer to 10 % glycerol for example, that means I add 10 % glycerol of the fat weight (excluding water, lye, etc.)

Superfat (or overfat) is unsaponified fat. You normally use less lye to convert all fatty acids into soap. First, because you don’t want to have unreacted lye in your soap (and on your skin ) and second the remaining fats are good for your skin.

) and second the remaining fats are good for your skin.

Due to the fact that every sort of fat needs a different amount of lye, we help ourself with a soap calculator.

I used this (in expert mode): Handmade by Kathrin - Seifenrechner (handmade-by-kathrin.de)

This works too: Lye Calculator - Soapee

Choose your fats/oil and the amount, decide for a lye (or in our case both and the ratio) and water content (around 20-30 %). Let the calculator does its magic happen and pick your recipe

To explain my recipe:

Stearic acid and palmitic acid are THE most important fatty acids. They stabilise the lather. That makes a soap to a shaving soap. Or you can shave in less than 2 minutes before your lather breaks in.

(some calculator also gives you a fatty acid distribution, in my recipe 50 % are stearic and palmitic acid)

Coconut gives your lather volume (and now you already have the final recipe of a famous expensive France soap ) You should not exceed 25 % coconut oil, it can try your skin in high amounts

) You should not exceed 25 % coconut oil, it can try your skin in high amounts

Castor act as a lather booster.

Mango and cacao give more stearic acid and due to its boiling points a more compact (non-bubbly) lather.

Every fat has its properties.

Back to topic.

For my recipe you need

We have balanced fats and oils, lye is mixed, so finally, we can cook soap.

We use the so-called “hot-process”.

Here we go. Your first shaving soap is ready to use. No need for waiting (reaction time) as we have to do with the cold process.

Dear wet shavers,

We have a holistic hobby and soap making can be a funny part of it (for some, soap making is a full hobby). But how to cook a good shaving soap. Some said, that cooking shaving soap is the Olympus in soap cooking. I don’t think so. I found it to be very easy (actually, I mucked my first bath soap attempt

But for the beginning we should jump into some theory (sorry, I know you want to play with chemicals, but you should know what you’re doing and why)

What is soap?

Simply said, it’s a salt. Yes, a salt. Made from an acid (fatty acid) and a metal ion (sodium and/or potassium in our case. (We recall from 9 th grade chemistry

The sodium salts of fatty acids are called “curd soap” (solid)

And the potassium salts are called “soft soap” (liquid)

Fatty acids are long hydrocarbon chains (from 6-22 carbon atoms) with a carboxyl group (COOH) at the end. E.g., a well-known carboxylic acid is vinegar (acetic acid) (with two carbon atoms in its chain).

Fat

Fat is the triple esther of glycerol (alcohol) and fatty acids. (there are more types of fat and lipids, but we’re looking for the triglycerides)

The differences in fats are the distribution of the bounded fatty acid. Every plant or animal fat have their own distribution.

This distribution of fatty acids makes later the lather properties.

Here is a little overview of typical fats/oils and their fatty acids

Table Fatty acid composition of selected oils and fats.xls (fediol.eu)

Deutsche Gesellschaft für Fettwissenschaft (dgfett.de)

Saponification

Saponification is a process of converting esters (fat) into soaps (salt of the fatty acid) and alcohols (glycerol) by the action of aqueous alkali (for example, aqueous sodium/potassium hydroxide solutions).

If you are interested in this topics (you should, a little bit, because soap making is organic chemistry (ester hydrolysis). Read some of the linked articles, pls.

Now the fun part, splash about chemicals.

The Soapmaking

Before we start:

We want to work with chemicals. So occupational safety is an issue. Lye is extremely corrosive for your skin and even worth for your eyes!

WEAR SAFTYGOGGLES AND GLOVES WHILE HANDLING LYE (and solid NaOH or KOH)!!

Keep Food and beverage away from your working space, don’t put chemicals (Lye) in beverage containers.

If lye gets into your eyes, wash with plenty of water (15 min !!!) and seek medical advice.

What do we need.

- Fats/oils

- Lye (NaOH and KOH)

- Water

- Cooking pot

- Extras (skincare, glycerol etc.)

As a starting point I’ll begin with my last recipe for explanation. (This is a larger batch [+/- 3kg], just adjust the amounts, if it’s to much)

As we are into science, I use the metric system (grams, °C)

- 600 g steric acid (33.3 %) (stearic acid is defined as a mixture of stearic and palmitic acid in various percentages, don’t get confused. In calculators, just handle it as pure stearic acid

- 350 g Coconut oil (19.4 %)

- 200 g Castor oil (11.1 %)

- 200 g Cocoa butter (11.1 %)

- 200 g Sweet almond oil (11.1 %)

- 200 g Mango butter (11.1 %)

- 50 g Beeswax (2.8 %)

Saponified with 5 % superfat (overfat) and dual lye (55 % KOH : 45% NaOH)

That’s how it’s calculated. Every percentage figures in soap recipes are related to the amount of total fat weight. So if I refer to 10 % glycerol for example, that means I add 10 % glycerol of the fat weight (excluding water, lye, etc.)

Superfat (or overfat) is unsaponified fat. You normally use less lye to convert all fatty acids into soap. First, because you don’t want to have unreacted lye in your soap (and on your skin

Due to the fact that every sort of fat needs a different amount of lye, we help ourself with a soap calculator.

I used this (in expert mode): Handmade by Kathrin - Seifenrechner (handmade-by-kathrin.de)

This works too: Lye Calculator - Soapee

Choose your fats/oil and the amount, decide for a lye (or in our case both and the ratio) and water content (around 20-30 %). Let the calculator does its magic happen and pick your recipe

To explain my recipe:

Stearic acid and palmitic acid are THE most important fatty acids. They stabilise the lather. That makes a soap to a shaving soap. Or you can shave in less than 2 minutes before your lather breaks in.

(some calculator also gives you a fatty acid distribution, in my recipe 50 % are stearic and palmitic acid)

Coconut gives your lather volume (and now you already have the final recipe of a famous expensive France soap

) You should not exceed 25 % coconut oil, it can try your skin in high amounts

) You should not exceed 25 % coconut oil, it can try your skin in high amountsCastor act as a lather booster.

Mango and cacao give more stearic acid and due to its boiling points a more compact (non-bubbly) lather.

Every fat has its properties.

Maybe a starting point for further discussions.

Back to topic.

For my recipe you need

- 110.58 g NaOH (99 % purity)

- 210.64 g KOH (85 % purty)

- Dissolved in 360 g Water [20 %] (yes, everything is measured by weight, not volume, even water)

- Caution, this is an exothermal reaction (getting hot), best to dissolve lye outside and use heat stabile ware. Remember: safety gear!

- ALWAYS place water first, then adding lye (base) slowly. Stir until everything is dissolved. Best use a stabile plastic stirrer

We have balanced fats and oils, lye is mixed, so finally, we can cook soap.

We use the so-called “hot-process”.

- We need do melt all (solid) ingredients. Especially stearic acid has a high melting point (69 °C)

- After all solid fats and stearic acid are melted, add the liquid oils and tempering the mixture to about 80 °C

- Add the lye-mixture, Caution, exothermal reaction!

- Stir well

- The mixture become quickly cloudy and solid, like potato smash

- Keep temperature up to 90 °C for about 10 minutes, stir from time to time.

- Now the saponification should be done. But how to check? Simple by taste. Just use your tip of your tongue. If you have a prickling feeling something went wrong. Then you have to much lye, or less fat. Does it taste just like soap, it’s good.

- Cool down to about 30 – 40 °C

- Add extras, if you want to (amounts are calculated to the total fat amount, of course)

- 10 % Glycerol (act as a transport agent for water and fat to bring it into your skin)

- 2.5 % Shea butter (skincare)

- 2.5 % Mango butter (skincare)

- 5 % Sodium lactate (water-holding management in your lather plus harden the soap a bit)

- 2-5 % Vitamin E (skincare)

- 5 % Lanolin (skincare) [if your remove lanolin, your recipe is vegan

]

]- 1 % clay is good, or 1 % silk protein (optional)

- Perfume (5 % of total soap weight, 10 % is a bomb, just play around

)

- I add perfume when I need the soap, just melt the soap (100g) in a microwave for 30 second (750 W) add pefume, stir, cool down.

Here we go. Your first shaving soap is ready to use. No need for waiting (reaction time) as we have to do with the cold process.

Last edited:

Very nice job! I have a few comments.DIY Cooking Shaving soap for beginners

Dear wet shavers,

We have a holistic hobby and soap making can be a funny part of it (for some, soap making is a full hobby). But how to cook a good shaving soap. Some said, that cooking shaving soap is the Olympus in soap cooking. I don’t think so. I found it to be very easy (actually, I mucked my first bath soap attempt)

But for the beginning we should jump into some theory (sorry, I know you want to play with chemicals, but you should know what you’re doing and why)

What is soap?

Simply said, it’s a salt. Yes, a salt. Made from an acid (fatty acid) and a metal ion (sodium and/or potassium in our case. (We recall from 9 th grade chemistry)

The sodium salts of fatty acids are called “curd soap” (solid)

And the potassium salts are called “soft soap” (liquid)

Fatty acids are long hydrocarbon chains (from 6-22 carbon atoms) with a carboxyl group (COOH) at the end. E.g., a well-known carboxylic acid is vinegar (acetic acid) (with two carbon atoms in its chain).

Fat

Fat is the triple esther of glycerol (alcohol) and fatty acids. (there are more types of fat and lipids, but we’re looking for the triglycerides)

The differences in fats are the distribution of the bounded fatty acid. Every plant or animal fat have their own distribution.

This distribution of fatty acids makes later the lather properties.

Here is a little overview of typical fats/oils and their fatty acids

Table Fatty acid composition of selected oils and fats.xls (fediol.eu)

Deutsche Gesellschaft für Fettwissenschaft (dgfett.de)

Saponification

Saponification is a process of converting esters (fat) into soaps (salt of the fatty acid) and alcohols (glycerol) by the action of aqueous alkali (for example, aqueous sodium/potassium hydroxide solutions).

If you are interested in this topics (you should, a little bit, because soap making is organic chemistry (ester hydrolysis). Read some of the linked articles, pls.

Now the fun part, splash about chemicals.

The Soapmaking

Before we start:

We want to work with chemicals. So occupational safety is an issue. Lye is extremely corrosive for your skin and even worth for your eyes!

WEAR SAFTYGOGGLES AND GLOVES WHILE HANDLING LYE (and solid NaOH or KOH)!!

Keep Food and beverage away from your working space, don’t put chemicals (Lye) in beverage containers.

If lye gets into your eyes, wash with plenty of water (15 min !!!) and seek medical advice.

What do we need.

- Fats/oils

- Lye (NaOH and KOH)

- Water

- Cooking pot

- Extras (skincare, glycerol etc.)

As a starting point I’ll begin with my last recipe for explanation. (This is a larger batch [+/- 3kg], just adjust the amounts, if it’s to much)

As we are into science, I use the metric system (grams, °C)

- 600 g steric acid (33.3 %) (stearic acid is defined as a mixture of stearic and palmitic acid in various percentages, don’t get confused. In calculators, just handle it as pure stearic acid

- 350 g Coconut oil (19.4 %)

- 200 g Castor oil (11.1 %)

- 200 g Cocoa butter (11.1 %)

- 200 g Sweet almond oil (11.1 %)

- 200 g Mango butter (11.1 %)

- 50 g Beeswax (2.8 %)

Saponified with 5 % superfat (overfat) and dual lye (55 % KOH : 45% NaOH)

That’s how it’s calculated. Every percentage figures in soap recipes are related to the amount of total fat weight. So if I refer to 10 % glycerol for example, that means I add 10 % glycerol of the fat weight (excluding water, lye, etc.)

Superfat (or overfat) is unsaponified fat. You normally use less lye to convert all fatty acids into soap. First, because you don’t want to have unreacted lye in your soap (and on your skin) and second the remaining fats are good for your skin.

Due to the fact that every sort of fat needs a different amount of lye, we help ourself with a soap calculator.

I used this (in expert mode): Handmade by Kathrin - Seifenrechner (handmade-by-kathrin.de)

This works too: Lye Calculator - Soapee

Choose your fats/oil and the amount, decide for a lye (or in our case both and the ratio) and water content (around 20-30 %). Let the calculator does its magic happen and pick your recipe

To explain my recipe:

Stearic acid and palmitic acid are THE most important fatty acids. They stabilise the lather. That makes a soap to a shaving soap. Or you can shave in less than 2 minutes before your lather breaks in.

(some calculator also gives you a fatty acid distribution, in my recipe 50 % are stearic and palmitic acid)

Coconut gives your lather volume (and now you already have the final recipe of a famous expensive France soap) You should not exceed 25 % coconut oil, it can try your skin in high amounts

Castor act as a lather booster.

Mango and cacao give more stearic acid and due to its boiling points a more compact (non-bubbly) lather.

Every fat has its properties.

Maybe a starting point for further discussions.

Back to topic.

For my recipe you need

The water amount is up to you, depending on how hard you want your soap (in this case it’s going to be on a harder side, but still soft)

- 110.58 g NaOH (99 % purity)

- 210.64 g KOH (85 % purty)

- Dissolved in 360 g Water [20 %] (yes, everything is measured by weight, not volume, even water)

- Caution, this is an exothermal reaction (getting hot), best to dissolve lye outside and use heat stabile ware. Remember: safety gear!

We have balanced fats and oils, lye is mixed, so finally, we can cook soap.

We use the so-called “hot-process”.

I use a water bath to not overheat the mixture (works pretty good)

- We need do melt all (solid) ingredients. Especially stearic acid has a high melting point (69 °C)

- After all solid fats and stearic acid are melted, add the liquid oils and tempering the mixture to about 80 °C

- Add the lye-mixture, Caution, exothermal reaction!

- Stir well

- The mixture become quickly cloudy and solid, like potato smash

- Keep temperature up to 90 °C for about 10 minutes, stir from time to time.

- Now the saponification should be done. But how to check? Simple by taste. Just use your tip of your tongue. If you have a prickling feeling something went wrong. Then you have to much lye, or less fat. Does it taste just like soap, it’s good.

- Cool down to about 30 – 40 °C

- Add extras, if you want to (amounts are calculated to the total fat amount, of course)

- 5 % Lanolin (skincare) [if your remove lanolin, your recipe is vegan

]

- Perfume (5 % of total soap weight, 10 % is a bomb, just play around

)

Here we go. Your first shaving soap is ready to use. No need for waiting (reaction time) as we have to do with the cold process.

There is a minimum amount of water that can be used that is capable of dissolving the lyes. Also you may want to mention that if you use very little water it get very thick and hard to put into molds whereas a bit largest water amount can assist in this. Shaving soap paste after cooking tends to be quite thick and a bit hard to deal with. I do see you added Sodium Lactate which does help with putting the soap in the molds though.

Most people are not familiar with glycerol, but are more familiar with glycerin. It is also easier to get, at least here in the US.

Be careful with the fragrance amounts. They are usually measured as a percentage of the oil weight only and fragrances has a maximum amount that you can use safely in soaps and other products for that matter. This is listed on datasheets when you purchase the fragrance/essential oil. Also need to pay attention to the flash point for the fragrance so that you do not add it when the paste is too hot, because then you loose the fragrance.

Cooking takes me much longer than 10 minutes. I would say around 30-45 minutes. The tonge-sap-test is good and works well, but if it saps you it may just mean that you need to cook it a bit longer to get it to saponify fully. Even better is to use a pH strip and take a bit soap paste with some water and check the pH. If it is in the 8-10 pH range it is finished. You might want to mention how the soap paste changes state from "mashed potato" look and eventually become more translucent and vaseline like, when complete.

Some other soaping calculator that are really popular are soapcalc.com (does not do dual lye so you have to do that yourself), lyecalc.com (my favorite and will do dual lye)

Yes your're right. But I reduced the water amount in my second soap. The first one was more a cream. My current batch is not so dry. maybe a bit harder than normal US artisans (A&E, Stirling)Very nice job! I have a few comments.

There is a minimum amount of water that can be used that is capable of dissolving the lyes. Also you may want to mention that if you use very little water it get very thick and hard to put into molds whereas a bit largest water amount can assist in this. Shaving soap paste after cooking tends to be quite thick and a bit hard to deal with. I do see you added Sodium Lactate which does help with putting the soap in the molds though.

How does your recipe work out? You use 83 % water (if there is not a misspelling) is it still solid or do you dry yours?

I don't put the soap into molds, just some bigger plastic jars with lid. As mentiond, my soap is ductile/kneadable so I haven't had any problems.

It the same molecule. Just another nameMost people are not familiar with glycerol, but are more familiar with glycerin. It is also easier to get, at least here in the US.

Good point. Scents and fragrances are a complete own world. I use normally 5 % of the total soap amount (not the fat amount) and be satisfied. Thats why I make the hole batch unscented and add fragrance later. Then you can play around.Be careful with the fragrance amounts. They are usually measured as a percentage of the oil weight only and fragrances has a maximum amount that you can use safely in soaps and other products for that matter. This is listed on datasheets when you purchase the fragrance/essential oil. Also need to pay attention to the flash point for the fragrance so that you do not add it when the paste is too hot, because then you loose the fragrance.

20-30 min will not ruin the soap. Just "tonge-sap-test" every 5-10 min. pH Paper works not so well. If you change the water amount you'll have different pH values. And soap/soap-water is always in an alkaline range. pH is not really suitible here.ooking takes me much longer than 10 minutes. I would say around 30-45 minutes. The tonge-sap-test is good and works well, but if it saps you it may just mean that you need to cook it a bit longer to get it to saponify fully. Even better is to use a pH strip and take a bit soap paste with some water and check the pH. If it is in the 8-10 pH range it is finished. You might want to mention how the soap paste changes state from "mashed potato" look and eventually become more translucent and vaseline like, when complete.

with soapcal the disadvantage is really the single lye limitation.Some other soaping calculator that are really popular are soapcalc.com (does not do dual lye so you have to do that yourself), lyecalc.com (my favorite and will do dual lye)

I don't know leycal,

just tested the soapee calculator. This works pretty good (dual lye and soy wax is listed too)

I think people will find a suitable (personal) calc.

The water that is put into making soap will evaporate during the "curing" process. Having a higher water content soap will give you a more porous soap and hence feel softer more pliable. However, the ration between the lyes have a far more impact on how soft a soap will be. My first soap I made had a 5:1 water ratio to lye amount and that is a bit much I realize, but you also loose water during the cook. Therefore, in hot process higher water content seems to be used as compared to cold process. More water also mean longer "cure" time to give it more time to evaporate.Yes your're right. But I reduced the water amount in my second soap. The first one was more a cream. My current batch is not so dry. maybe a bit harder than normal US artisans (A&E, Stirling)

How does your recipe work out? You use 83 % water (if there is not a misspelling) is it still solid or do you dry yours?

I don't put the soap into molds, just some bigger plastic jars with lid. As mentiond, my soap is ductile/kneadable so I haven't had any problems.

It the same molecule. Just another name(Glycerin is the old; glycerol the official new name [since the 1990th]. As it's an alcohol, which the ending -ol indicates.

Good point. Scents and fragrances are a complete own world. I use normally 5 % of the total soap amount (not the fat amount) and be satisfied. Thats why I make the hole batch unscented and add fragrance later. Then you can play around.

20-30 min will not ruin the soap. Just "tonge-sap-test" every 5-10 min. pH Paper works not so well. If you change the water amount you'll have different pH values. And soap/soap-water is always in an alkaline range. pH is not really suitible here.

with soapcal the disadvantage is really the single lye limitation.

I don't know leycal,

just tested the soapee calculator. This works pretty good (dual lye and soy wax is listed too)

I think people will find a suitable (personal) calc.

I also put soap in plastic containers, but it is always quite think and globby. If you however want to mold it into pucks you have to be fairly quick, before it cools, to do so and compact it well so that it does not look a mess.

Glycerin and Glycerol is not quite the same. They are the compound propane-1,2,3-triol, and Glycerol is the pure variety and Glycerin is not pure, but about 95%. Glycerin is easy to obtain in any pharmacy here in the US, whereas Glycerol you have to order from chemical supply places. Both will both fine in soap, but one is easier to obtain.

Be careful of using total weight for determining fragrance levels. Remember the water evaporates and now you have a higher concentration of the fragrances. You may end up with too much after curing and that may cause irritation depending on the recommended maximum percentage. Each fragrance have it's own maximum concentration that you should not exceed.

For example here is peppermint essential oil. You can use MAX 5% of oil weight. Water evaporate

This is spearmint essential oil. For this essential oil you are supposed to keep it below 0.2% MAX of the oil weight.

Be careful so you do not cause skin issues! I know we like a strong scent, but we have to be careful.

pH has to be in the range of 8-10 pH for it is safe for skin use. The pH before saponification is quite a bit higher and it drops during the cook. The zap test works fine, but if you feel a bit weird about putting soap on your tongue you can use a pH strip. It will work just fine. The water amount only effect it marginally. The look of the cooked finished soap is also vastly different than the soap before it is cooked. Very translucent looking.

Yes soapcalc only handles single lye soaps unless you divide it up and do the calculation twice and if you are a beginner I would not recommend doing that. This is the reason I suggested lyecalc, which does handle dual lye nicely. It also handles adding things like citric acid and calculating the additional lye that needs. I use citric acid in mine to keep down the soap scum in the sink and also makes it work better with hard water. The non-german one you suggested seems to also handle dual lye. Many good ones out there. Math is not really that hard. I made my own spreadsheet once upon the time and it worked fine as well.

I used a lidThe water that is put into making soap will evaporate during the "curing" process. Having a higher water content soap will give you a more porous soap and hence feel softer more pliable. However, the ration between the lyes have a far more impact on how soft a soap will be. My first soap I made had a 5:1 water ratio to lye amount and that is a bit much I realize, but you also loose water during the cook. Therefore, in hot process higher water content seems to be used as compared to cold process. More water also mean longer "cure" time to give it more time to evaporate.

Sorry, it is the same. (IUPAC)Glycerin and Glycerol is not quite the same. They are the compound propane-1,2,3-triol,

In the second case it’s just glycerol with water (mixture). You named it Propane-1,2,3-triol will not change if you add water (it will „suck“ water from air anyway, if you leave the bottle open).

Fragrance is such a personal thing, everybody has to find out for themselves. One is sensitive (skin) other not. Some like strong scents, others not. Depending with fragrance oil/perfume you use the max amount is different.

My recipe is only a suggestion, or the way I cook my soap. And that’s the main issue. We are here to cook ourselves soap. Take it as a starter an develop an own. Luckily we are all different, otherwise we had only one soap, one razor one aftershave and so on….

...To explain my recipe:

Stearic acid and palmitic acid are THE most important fatty acids. They stabilise the lather. That makes a soap to a shaving soap...

Coconut gives your lather volume (and now you already have the final recipe of a famous expensive France soap) You should not exceed 25 % coconut oil, it can try your skin in high amounts

Castor act as a lather booster.

Mango and cacao give more stearic acid and due to its boiling points a more compact (non-bubbly) lather.

Every fat has its properties.

Maybe a starting point for further discussions.

There is a particular artisan soap I have tried and liked that uses an unusual recipe.

Ingredients: Cocoa Butter, Kokum Butter, Illepe Butter, Stearic Acid, Glycerin, Coconut Oil, Lye (KOH), Reconstituted Aloe Juice, Goat Milk, Myristic Acid, Lye (NaOH), Lanolin, Castor Oil, Bentonite Clay, Fragrance (If applicable), Tussah Silk

There's a high concentration of butters and not much coconut oil. It also has Milk, Bentonite Clay and the Silk Protein.

Does using these butters really have a big impact on the soap performance? Since only the fractional fatty acids matter in the final product (other than overfat & superfat)?

I do like the recipe and might try to make something similar. I'm not sure about how cost effective it would be with the more exotic ingredients, though.

Last edited:

The question is, is the list sorted by amount?

All of the mentioned butters have a high stearic acid content. Milk and or aloe juice just substitute water (plus some benefits). You can use apple juice, if you'd like to.

But it looks like a pretty nice recipe.

Exotic butters are not the problem when it comes to cost efficiency. Perfumes are.

All of the mentioned butters have a high stearic acid content. Milk and or aloe juice just substitute water (plus some benefits). You can use apple juice, if you'd like to.

But it looks like a pretty nice recipe.

Exotic butters are not the problem when it comes to cost efficiency. Perfumes are.

The question is, is the list sorted by amount?

All of the mentioned butters have a high stearic acid content. Milk and or aloe juice just substitute water (plus some benefits). You can use apple juice, if you'd like to.

But it looks like a pretty nice recipe.

Exotic butters are not the problem when it comes to cost efficiency. Perfumes are.

Yes, the ingredient list is in order by the relative amounts. I guess I was wondering about the benefits of the butters as the primary fat source in the soap. Does it really improve the soap or is it just for marketing & glamour? I do like the idea of making something a bit out of the mainstream.

The main benefit is the source of stearic acid. And they removed tallow. If you remove something, you have to substitute that. One strategy is to add more stearic acid. But that is only a fatty acid, which does nothing for the lather, except for stability. On the other hand, if you use other fats (which includes glycerol for the saponification process and other fatty acids) you change the properties of your lather. And a higher butter content also makes the lather more dense (I found so)

I ran the ingredient list through lyecalc with a 60%KOH, 40% NaOH and this is probably close to what the recipe would be. I used 3.5:1 water ratio which is x3.5 the lye amount by weight. It will be a nice creamy soap that has good longevity. The milk will add a bit creaminess as well, but you have to be a bit careful not to scorch it. Make will try to keep it cool while you make the lye water. The other additives will not effect this calculation. I would probably do around 10% glycerin of the oil weight so about 100g in this 1000g recipe.There is a particular artisan soap I have tried and liked that uses an unusual recipe.

Ingredients: Cocoa Butter, Kokum Butter, Illepe Butter, Stearic Acid, Glycerin, Coconut Oil, Lye (KOH), Reconstituted Aloe Juice, Goat Milk, Myristic Acid, Lye (NaOH), Lanolin, Castor Oil, Bentonite Clay, Fragrance (If applicable), Tussah Silk

There's a high concentration of butters and not much coconut oil. It also has Milk, Bentonite Clay and the Silk Protein.

Does using these butters really have a big impact on the soap performance? Since only the fractional fatty acids matter in the final product (other than overfat & superfat)?

I do like the recipe and might try to make something similar. I'm not sure about how cost effective it would be with the more exotic ingredients, though.

A few more thingsYes, the ingredient list is in order by the relative amounts. I guess I was wondering about the benefits of the butters as the primary fat source in the soap. Does it really improve the soap or is it just for marketing & glamour? I do like the idea of making something a bit out of the mainstream.

I would keep the lanolin out of the cook and add it at the end to ensure that you get the full skin benefit of it. This way it does not get saponified. Also add the glycerin and the fragrance at the end. Just watch the temperature when you add it so it is not too hot. The fragrance will loose a lot of it's scent if it is too hot. The fragrance datasheet will tell you at which temperature this will happen.

If you choose to use the bentonite clay, mix that in with the melted fats/oils priors to adding the lye water. The aloe juice/goat milk is your liquid (water)

Yeah you can use many different kinds of liquids in soap making. Just be careful if it has a lot of sugar in it, because it can cause a pretty good reaction when the lye is added and you may end up with a "volcano".The question is, is the list sorted by amount?

All of the mentioned butters have a high stearic acid content. Milk and or aloe juice just substitute water (plus some benefits). You can use apple juice, if you'd like to.

But it looks like a pretty nice recipe.

Exotic butters are not the problem when it comes to cost efficiency. Perfumes are.

Yeah, why not having some extra fun.you may end up with a "volcano".

Sugar with sulfuric acid is even funnier.

But your are right. Safety first when handling chemicals.

Similar threads

- Replies

- 31

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 37

- Views

- 2K