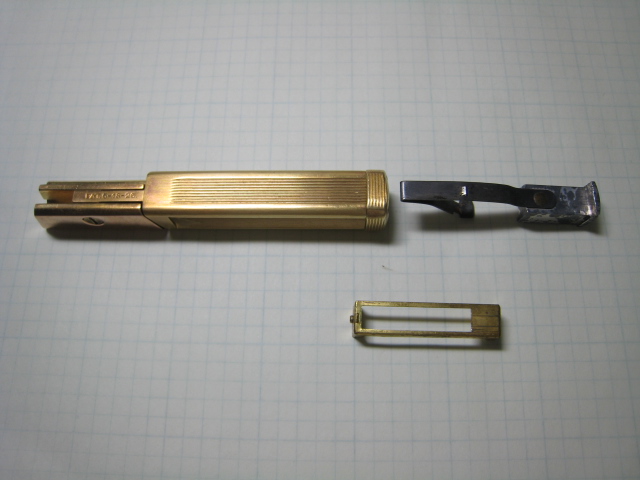

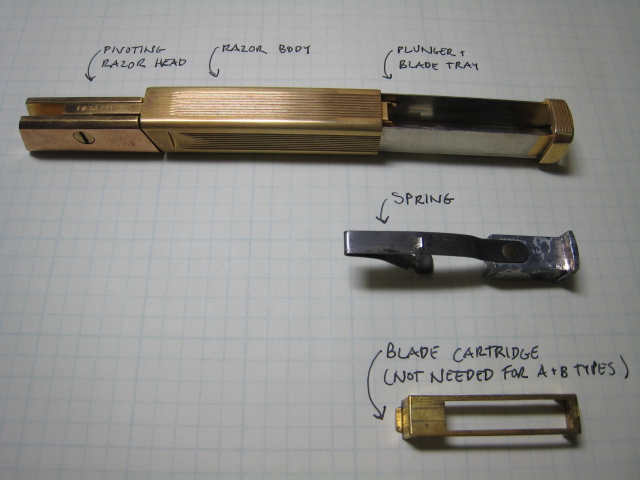

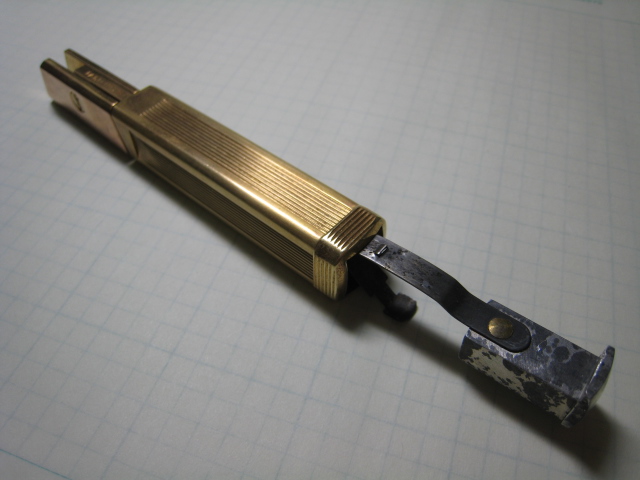

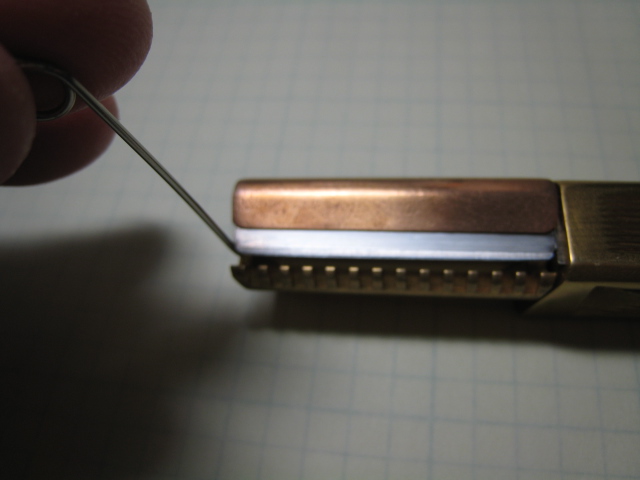

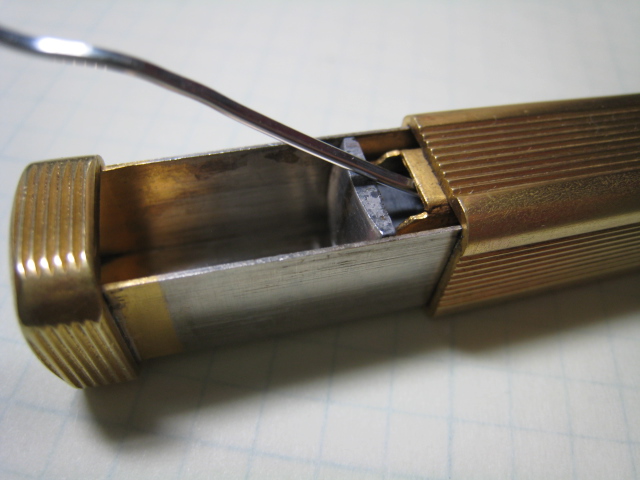

I recently bought a Schick B2 off eBay and, unfortunately, I think it is out of commission. I am unsure how you load a blade into it, but my presumption is that you (somehow) load blades into the handle, then push the square button on the bottom of the handle to load blades while it is in the folded position. Can anyone confirm that? Sadly, there is a blade stuck in the "chamber" - see second photo - and I have been unable to get it out. If anyone has any experience with this model and can offer any advice I would appreciate it. Otherwise, it may make a nice paperweight.

Thanks.

View attachment 91119

View attachment 91120

View attachment 91121

Thanks.

View attachment 91119

View attachment 91120

View attachment 91121

.

.