Gents,

Working on two restore projects for myself. One is a Joseph Allen with MOP and the other is a Henckels with MOP.

Ive unpinned them (MUCH trickier than ivory in my opinion), polished the metal liners, and re-glued the pivot side liner to MOP with some 330 epoxy.

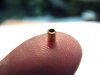

Now its time to pin em' back. The exit holes on the MOP sid measure about 5/64" and the hole in the liner is 1/16". Any tips on how how to go about this besides- "carefully"?

Whats the best way to polish these bad boys up and keep them in good shape?

MUCH appreciated!!!​

Working on two restore projects for myself. One is a Joseph Allen with MOP and the other is a Henckels with MOP.

Ive unpinned them (MUCH trickier than ivory in my opinion), polished the metal liners, and re-glued the pivot side liner to MOP with some 330 epoxy.

Now its time to pin em' back. The exit holes on the MOP sid measure about 5/64" and the hole in the liner is 1/16". Any tips on how how to go about this besides- "carefully"?

Whats the best way to polish these bad boys up and keep them in good shape?

MUCH appreciated!!!​