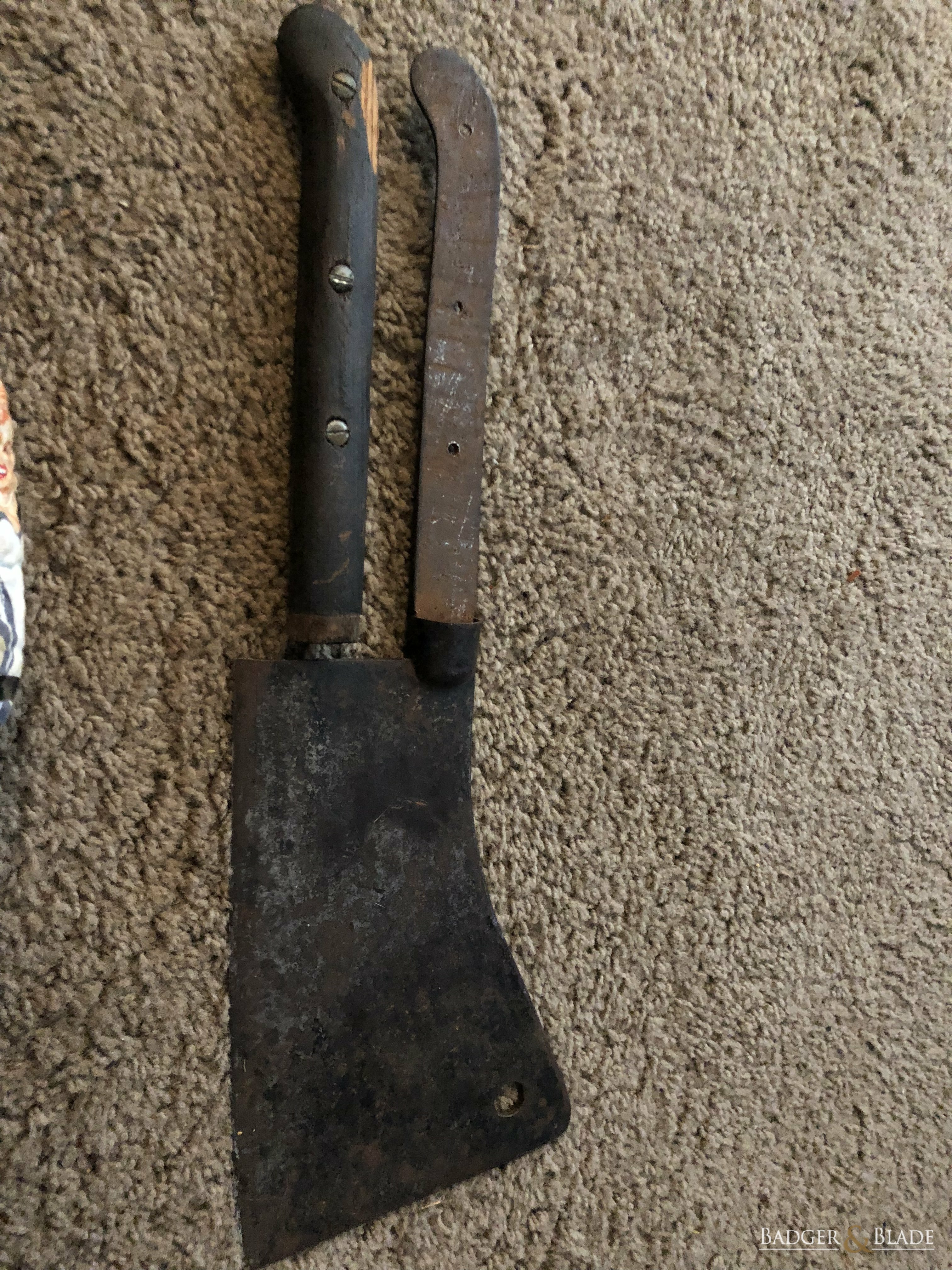

I have spent an incredible amount of time on youtube researching how to restore rusty old tools, such as axes and knives. This christmas I was gifted a massive Cleaver that has a little surface rust and what looks like "old" pitting. I removed the handles, are they still called scales if the implement is like 5 pounds? These pieces of wood are incredibly light, and were bolted into place. I'm guessing this was not original.

I have two main concerns, the biggest is this being a cleaver that may be used for meat how aggressive does a person need to be to get the pitting out? I read peoples comments saying that these pits can harbor bacteria and KILL you. I imagine this is a worst case scenario, though i tend to have a bit of a laissez-faire attitude so give me your thoughts? My plans are to soak the blade in vinegar and see what condition the blade will be in once that's done and decide from there.

Upon removing it from vinegar does anyone have suggestions as to how to minimize the flash rust that happens?

The second concern that i have is the handles themselves, being that they're likely not original is there merit in trying to repair them (even though they have bolts in them, and the nuts look epoxied into place?) I've read if you soak them in mineral oil it would be a great job restoring old wood...maybe i read it about horn? most of the stuff that i've read over the years has been on straight razors, sorry! My plan is to use a different kind of wood, possibly Maple. It seems that a large percentage of Youtubers i have watched prefer using oak though, i'm not sure if there is a specific reason for this. I would choose Maple because of the heft which can help balance a 10" cleaver, and that the wood has less porosity for the aforementioned bacteria to grow.

If anyone has feedback, advice, recommendations, or anything to add please let me know. For anyone who may be curious, it's a Samuel Lee Knives and steels LF&C size 10. *edit* i'm not sure why i wrote butcher knife in the title, but i'm not sure how to change it. I guess i got excited to hear everyones advice

I have two main concerns, the biggest is this being a cleaver that may be used for meat how aggressive does a person need to be to get the pitting out? I read peoples comments saying that these pits can harbor bacteria and KILL you. I imagine this is a worst case scenario, though i tend to have a bit of a laissez-faire attitude so give me your thoughts? My plans are to soak the blade in vinegar and see what condition the blade will be in once that's done and decide from there.

Upon removing it from vinegar does anyone have suggestions as to how to minimize the flash rust that happens?

The second concern that i have is the handles themselves, being that they're likely not original is there merit in trying to repair them (even though they have bolts in them, and the nuts look epoxied into place?) I've read if you soak them in mineral oil it would be a great job restoring old wood...maybe i read it about horn? most of the stuff that i've read over the years has been on straight razors, sorry! My plan is to use a different kind of wood, possibly Maple. It seems that a large percentage of Youtubers i have watched prefer using oak though, i'm not sure if there is a specific reason for this. I would choose Maple because of the heft which can help balance a 10" cleaver, and that the wood has less porosity for the aforementioned bacteria to grow.

If anyone has feedback, advice, recommendations, or anything to add please let me know. For anyone who may be curious, it's a Samuel Lee Knives and steels LF&C size 10. *edit* i'm not sure why i wrote butcher knife in the title, but i'm not sure how to change it. I guess i got excited to hear everyones advice