A simultaneous goodmorning, good day and good evening forumites. And good night I guess. Why not.

I wanted to know what the fuzz about superstone was all about so I got some of those smaller pieces you sometimes see at the stone hustlers, and instead of buying the 8 x 3 x whatever, maybe there's something to experiment with in the awfully tiny ones.

The teeth of the blade was down to half of its original size. Sawed it under running water.

Flatted the down side of the pieces and marked the joining ends or whatever. Important thing because the ends weren't exactly at 90° so flipping them around for a while seemed to make sense, since more lapping needed to be done, more or less stone needed to come off depending on how the pieces where combined, hence the markings. Just to remember.

Correcting the end surface on some w/d paper glued to squared wood. Totally unnecessary when I discovered that you can just put a diamond plate and put it against the (aw man I run out of English woodworking terms... "Anhållet" if your Swedish)90 degree surface and flatten kinda upright. Leads to more play and uncertainties perhaps but pretty fast and pretty mobile.

OK so sorry if I rant about details here but perhaps that's what you're here for.

The w/d gleud to wood-thingy left a Un joined surface at the bottom of the stones. I didn't want to touch the joining ends again but a tiny chamfer solved the problem. Still further flattening was needed, so thanks naniwa for supersoft superstone 1000. Like that 3 stone flattening thing but with a twist. Going slo was key.

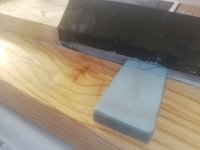

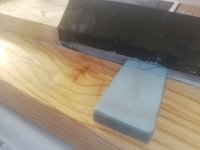

So the stones needed some substrate, and I happened to have quartersawn teak at home so why not. If you wonder what that might be, look at the rings in these pieces. The brown teak to the right is quartered, and the thicker ash to the left, is not.

Having the rings in a certain direction leaves you with wood that moves less.(read boat decks) Don't want to do end up with a banana in the end you know...

Some nasty isocyanate glue. But it works both with the stone AND the teak, that can be problematic to glue to it self due to being rich in oil and gunk and such.

Some length adjustment was needed, some chamfering, some sanding of the sides and scraping off glue residue. Masked the stone with tape and gave the handle a coat of Danish oil, som more lapping was done to the topside, and that's that. Getto superstones.

If you "can't feel the glue joint" in secondhand dropped coticules I'd say it's nearly non existent on these. So far any way!

I wanted to know what the fuzz about superstone was all about so I got some of those smaller pieces you sometimes see at the stone hustlers, and instead of buying the 8 x 3 x whatever, maybe there's something to experiment with in the awfully tiny ones.

The teeth of the blade was down to half of its original size. Sawed it under running water.

Flatted the down side of the pieces and marked the joining ends or whatever. Important thing because the ends weren't exactly at 90° so flipping them around for a while seemed to make sense, since more lapping needed to be done, more or less stone needed to come off depending on how the pieces where combined, hence the markings. Just to remember.

Correcting the end surface on some w/d paper glued to squared wood. Totally unnecessary when I discovered that you can just put a diamond plate and put it against the (aw man I run out of English woodworking terms... "Anhållet" if your Swedish)90 degree surface and flatten kinda upright. Leads to more play and uncertainties perhaps but pretty fast and pretty mobile.

OK so sorry if I rant about details here but perhaps that's what you're here for.

The w/d gleud to wood-thingy left a Un joined surface at the bottom of the stones. I didn't want to touch the joining ends again but a tiny chamfer solved the problem. Still further flattening was needed, so thanks naniwa for supersoft superstone 1000. Like that 3 stone flattening thing but with a twist. Going slo was key.

So the stones needed some substrate, and I happened to have quartersawn teak at home so why not. If you wonder what that might be, look at the rings in these pieces. The brown teak to the right is quartered, and the thicker ash to the left, is not.

Having the rings in a certain direction leaves you with wood that moves less.(read boat decks) Don't want to do end up with a banana in the end you know...

Some nasty isocyanate glue. But it works both with the stone AND the teak, that can be problematic to glue to it self due to being rich in oil and gunk and such.

Some length adjustment was needed, some chamfering, some sanding of the sides and scraping off glue residue. Masked the stone with tape and gave the handle a coat of Danish oil, som more lapping was done to the topside, and that's that. Getto superstones.

If you "can't feel the glue joint" in secondhand dropped coticules I'd say it's nearly non existent on these. So far any way!