You see it on the tang maker's mark a lot. Why can I hit that with 100 passes of 180 grit with minimal impact, yet the stamping is often obliterated. By the much smoother, softer scales that are lightly touching it??? Seems like it would take about 1.5 eons for that to happen!

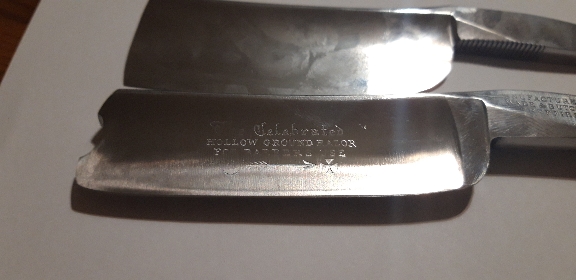

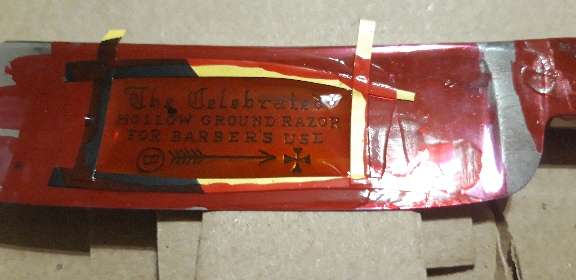

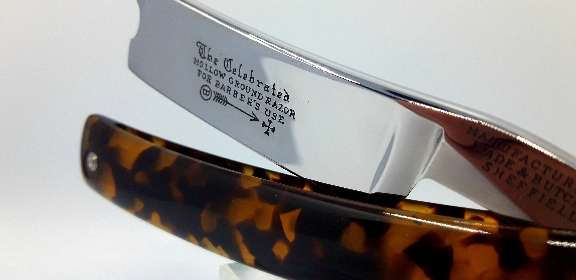

Here's a blade (under LED and fluorescent lighting)that looks to me to be remarkably unhoned. Like, there is no visible bevel and the wear on the spine is not even polished. Yet, the blade etching? It has left the building! What am I missing here? Am I completely misreading the level of honing? Hell, why should honing ever wear the etching in the hollow of the blade? Maybe the blade has been resurfaced, but I think I see some pretty visible grind marks. Help an ignorant brother out!

Here's a blade (under LED and fluorescent lighting)that looks to me to be remarkably unhoned. Like, there is no visible bevel and the wear on the spine is not even polished. Yet, the blade etching? It has left the building! What am I missing here? Am I completely misreading the level of honing? Hell, why should honing ever wear the etching in the hollow of the blade? Maybe the blade has been resurfaced, but I think I see some pretty visible grind marks. Help an ignorant brother out!