- Thread starter

- #181

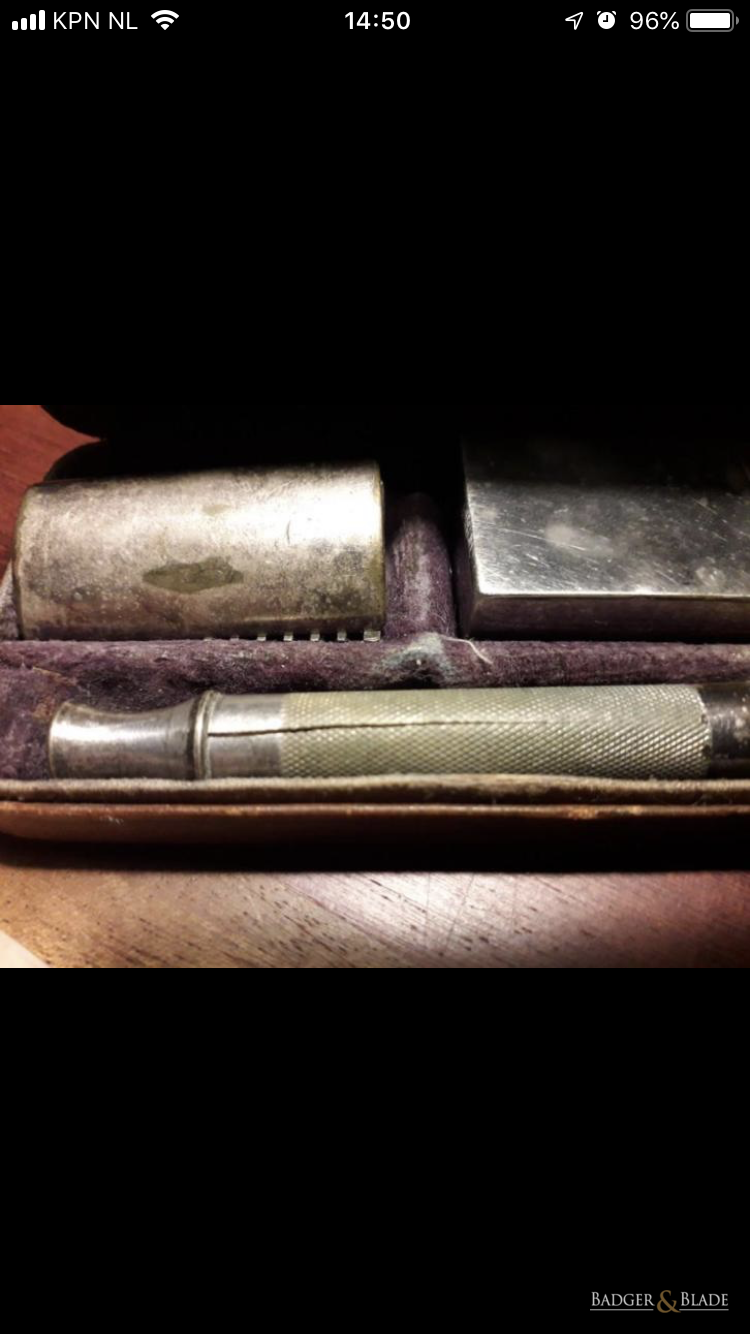

I've done it several times (if they were already loose). No problem.I was wondering if anyone has done that? I'd like to leave it in original condition but it's going to crack one day. I'd like to save it from happening.

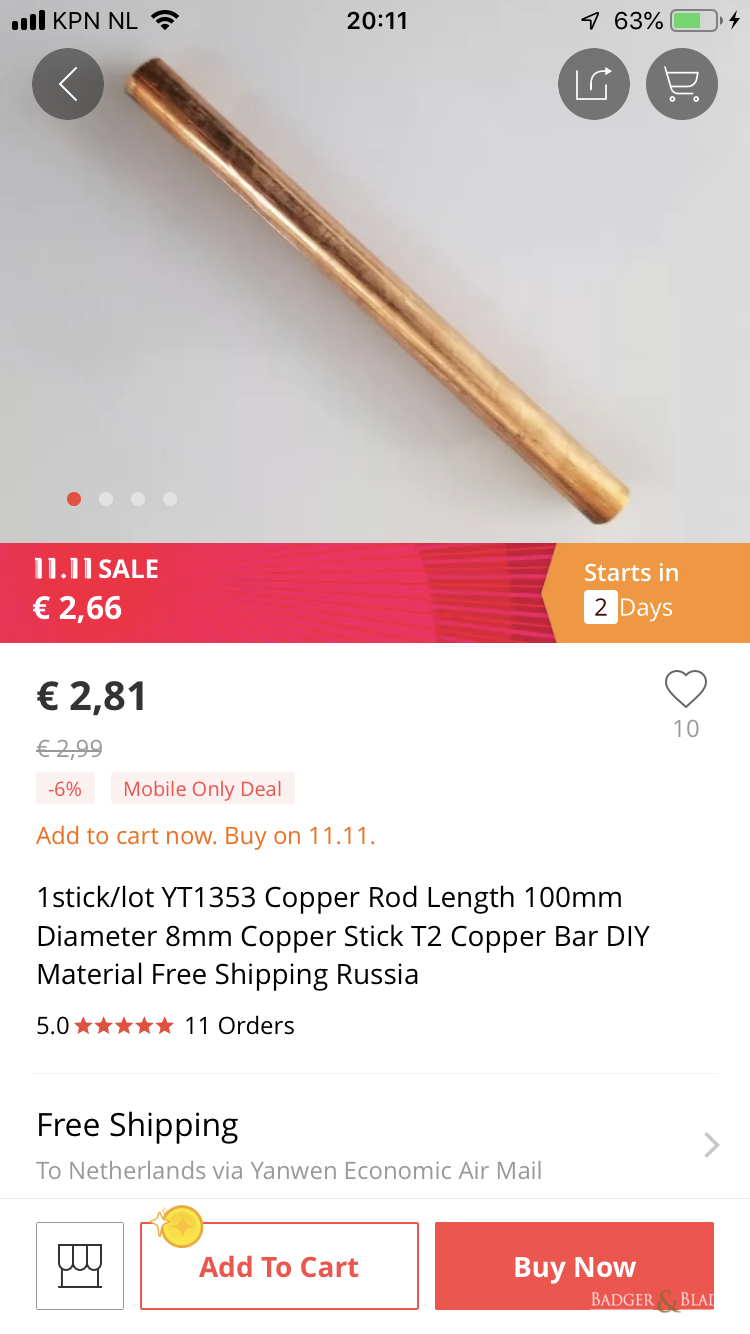

View attachment 860410

As to the marine epoxy residue; did you follow up with Q-Tips and alcohol before it dried? I always do and never have residue worth mentioning.....and I'm very picky.

Great job btw.