blade edge exposure

US 2848806 A

Abstract available in

Images(4)

Claims available in

Description (OCR text may contain errors)

Aug. 26, 1958 M. J. SHNITZLER ETAL 2,848,806

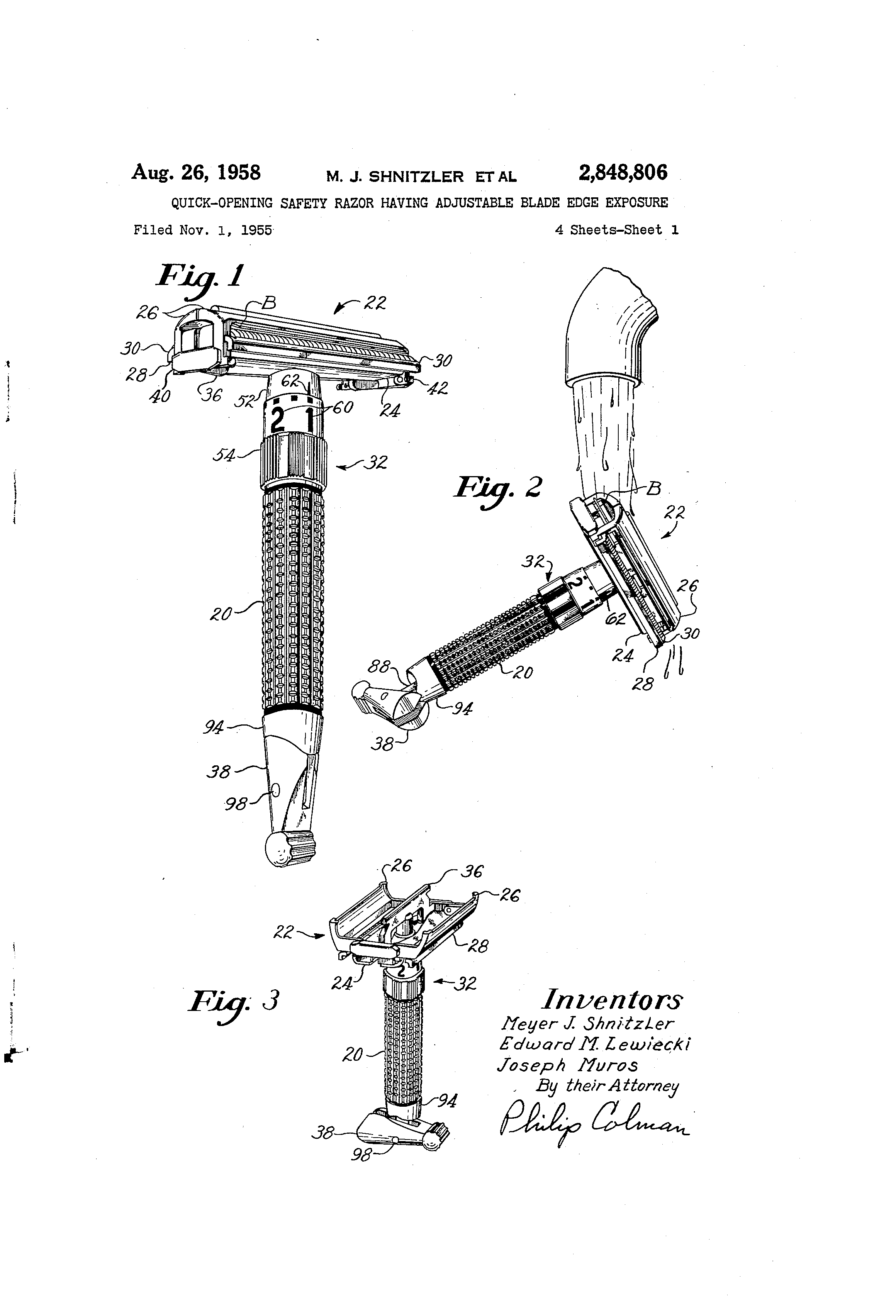

QUICK-OPENING SAFETY RAZOR HAVING ADJUSTABLE BLADE EDGE EXPOSURE Filed Nov. 1, 1955- 4 Sheets-Sheet 1 Inventors Meyer J Slmf-zzLer 'dwarofl Lewz'eqki Joseph [Yul-0s By zhez'rAztomey 6, 1958 M. J. SHNITZLER ETAL 2,348,806

QUICK-OPENING SAFETY RAZOR HAVING ADJUSTABLE BLADE EDGE EXPOSURE Filed Nov. 1, 1955 4 Sheets-Sheet 2 m ww illl/lll Aug. 26, 1958 M. J. SHNITZLER ETAL 2,848,806 QUICK-OPENING SAFETY RAZOR HAVING ADJUSTABLE BLADE EDGE EXPOSURE Filed Nov. 1, 1955 4 Sheets-Sheet 3 ntors Heyerj s/mitzler lew kl' JOfieph [f 06 M. J. SHNITZLER ETAL 2,848,806

Aug. 26, 1958 QUICK-OPENING SAFETY RAZOR HAVING ADJUSTABLE BLADE EDGE EXPOSURE v 4 Sheets-Sheet 4 Inventors J05 eph 17 uros 5y {heir-A zzarney United States Patent QUICK-OPENING SAFETY RAZOR HAVING ADJUSTABLE BLADE EDGE EXPOSURE Meyer Joseph Slmitzler, Brookline, Edward Michael Lewiecki, Hingham, and Joseph Muros, Newtonville, Mass. assignors to The Gillette Company, Boston, Mass., a corporation of Delaware Application November 1, 1955, Serial No. 544,226

11 Claims. (Cl. 30-605) The present invention relates to safety razors and in certain respects represents an improvement in quickopening razors of the type disclosed in Muros Patent No. 2,644,229, granted July 7, 1953. However, in its broader aspects it will be recognized that this invention is not limited in its use to that or indeed any specific type of razor or razor construction.

The razor of our present invention may be quickly manipulated either to clamp a blade in shaving position, replace the blade, or retain it on the razor head in a loose manner While the razor head is being rinsed. Further, our construction provides an adjustment which will enable the user to control the exposure of the shaving blade to suit his individual requirements while at the same time providing a razor which will operate with utmost reliability.

It is an object of our invention to provide a quickopening razor having a rinse position incorporated in a structure providing means for adjusting the edge exposure of the razor blade, enabling the razor head to be cleaned with the blade retained thereon and then quickly returned to a pre-adjusted position with the desired exposure of the blade edge.

Another object of the present invention is to provide an improved quick-opening razor of the so-called toggletype.

Still another object of the present invention is to provide an improved razor construction having means for effecting relative adjustment between a razor guard and the razor blade to vary the edge exposure of the blade.

Still another object of the invention is to provide an improved arrangement for mounting a blade in the head portion of a razor having means for effecting relative adjustment between the guard of the razor and the blade edge.

It is likewise an object of our invention to provide a razor having means for adjusting the edge exposure of the razor blade and means for releasably maintaining incremental adjustments of that exposure, correlated to externally-visible indicia.

A further object of the invention is to provide a simplified razor construction having readily manipulable means for moving blade-clamping members to a fullyopen position for blade replacement, a partially-open position wherein a blade is loosely retained for rinsing, or a clamped position when the razor is held for use in shaving. -z one aspect of our invention includes a safety razor having a hollow handle, at one end of which is disposed 'aJheadportion wherein are found two members between which ,a blade may be clamped, one of which connects with. an axially-movable stem assembly, provided for bringing these members into and out of blade-clamping =relation. This stern assembly has two relatively movable members interconnected by a pre-stressed coil spring. A toggle or finger-piece is pivotally connected to a portion of the stem which extends beyond the other end of :the hollow handle; this finger-piece co-acts with the other end of the handle to impart axial movement to the stem to bring the mentioned members into clamping relation under a pre-loaded pressure determined by the pre-stressed spring.

In another aspect our invention comprises a safety razor having a hollow handle having a head portion disposed at one of its ends. The head portion includes a guard and two members for clamping a blade in shaving relation with respect to the guard, a manually-adjustable exten sible substantially-rigid connection is interposed between one of the members and the handle. This connection means may be adjusted to establish a desired relationship between the guard and that member. There is further provided manually-operable, motion-transmitting means for bringing the other clamping member into and out of clamping relation. These further means extend through and beyond the other end of the handle.

Yet another aspect of the invention contemplates a safety razor having improved means for supporting a blade which is to be adjusted with respect to a guard member. In this construction a platform is provided having upturned edges which preferably are formed with blade-supporting surfaces of substantial area to prevent introduction of undue stress concentration when the blade is clamped thereon.

A further aspect of the invention is found in a razor having means for adjusting a blade relative to a guard, with means being provided to releasably maintain incremental adjustments thereof. This end is accomplished by detent means which have a fixed relationship to indicia markings indicating the adjusted position of the blade.

Additionally another aspect of our invention contemplates a safety razor comprising a hollow handle having a head portion disposed at one end thereof. This head portion includes two clamping members which are relatively movable into three different positions, a clamping position wherein a blade is operatively clamped therebetween for use in shaving, a partially open position in which the razor blade is loosely confined in the razor head for rinsing, and a fully open position for blade replacement. Manually operable, motion transmitting means connect with one of the members for controlling its position. These motion-imparting means are then provided with three separate and distinct selectable settings corresponding to the three relative positions of the clamping members.

The invention further embraces various combinations of the structures referred to in the various aspects described above.

The above and other aspects of the invention will now be more fully described by reference to the accompanying drawings and the particular novelty thereof pointed out in the claims.

In the drawings:

Fig. 1 is a perspective view of an illustrative embodiment of our improved razor construction shown in readiness for use in shaving;

Fig. 2 is another perspective view of our razor showing the head portion in a partially open or a rinse position;

' Fig. 3 is a further perspective view of our razor showing it in a fully open position for blade replacement;

Fig. 4 is an exploded view of the various elements comprising our razor;

Fig. 5 is an elevation of the razor seen in Fig. 1 with certain portions in longitudinal section;

Fig. 6 is a section taken along the line 6-6 in Fig. 5 With the razor adjusted to provide minimum exposure of the blade edge;

Fig. 7 is a section similar to that shown in Fig. 6 with the razor adjusted to give a greater exposure of the blade edge;

Fig. 8 is a section taken along the line 8-8 in Fig. with certain motion-transmitting portions shown in a position corresponding to Fig. 2 and other portions indicated in phantom, in a position corresponding to that shown in Fig. 3;

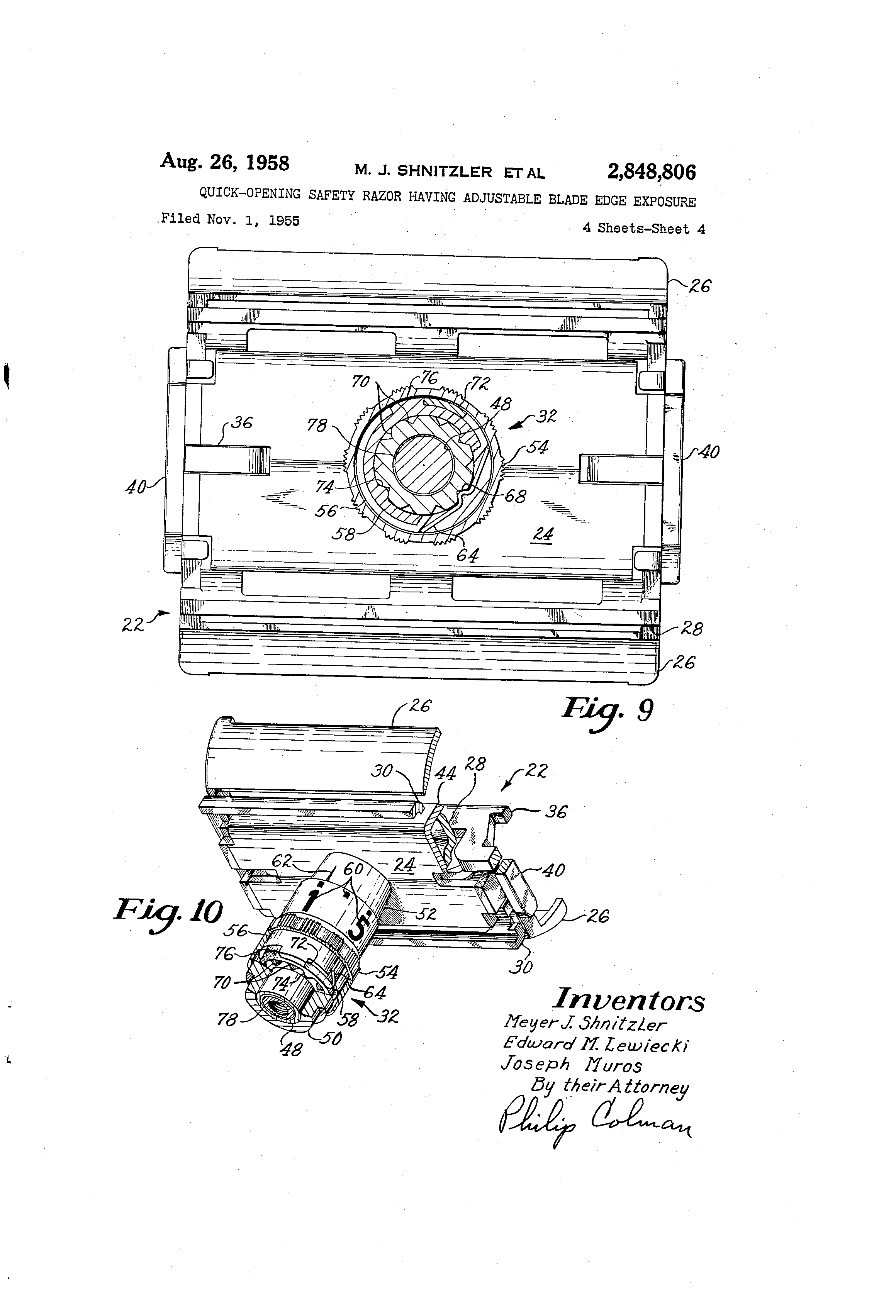

Fig. 9 is a section taken along the line 99 in Fig. 5 on an enlarged scale and with the blade-clamping cap sections shown in the position seen in Fig. 3; and

Fig-.10 is a perspective view of the razors head portion showing the cap sections in their fully open position and certain portions of the blade exposure adjusting means, portions of which are broken away and others are in section.

The three operative positions of our improved razor arebest seen on the first sheet of the accompanying drawings. In Fig. l. the razor is as it would be when used for shaving. In Fig. 2, the razor is shown in its rinse position beneath a stream of water indicating how simply it may be cleaned'after it has been used; In Fig. 3 the razor is shown in a fully open position for replacement of the shaving blade.

This razor, in accordance with the various aspects of the invention, may include a hollow handle 2% at one end of which, conveniently referred to as the upper end, is disposed a head portion 22 whereon a blade B may be mounted for use in shaving. The head portion includes blade-clamping members, which are herein illustrated as a platform 24 and cap sections 2-6 which serve as a composite clamping member to clamp the blade 3- against the platform 24 for use in shaving.

Conventionally, a guard is provided in safety razors in shaving relation relative to the blade. In accordance with our-invention, it may take the form of a separate element, as the guard member 28 having guard surfaces 36 in shaving relation with respect to the blade B. This shaving-relation between the blade and the guard may be varied by establishing the guard member 28 in a fixed position relative to the handle 20. Then a manuallyadjustable extensible substantially-rigid connection, indicated generally by the reference character 32, between the handle 26 and the platform 24 may be manipulated to effect relative adjustment between the edges of the blade B and the guard surfaces 36 (Figs. 6 and 7). Thus theshaving relation of the blade B with respect to the guard surfaces 36 may be adjusted to suit the needs of the individual using the razor.

An axially-movable stem, indicated generally by the reference character 34 in Fig. 5, may connect with the cap sections 26 through a spider 36 to control the relative position between the two blade-clamping members in the manner described in the lduros Patent No. 2,009,272, dated July 23, 1935. Axial movement of this stem may be controlled by a finger-piece or toggle 38 which has three separate and distinct positions corresponding to the three positions of our razor seen in Figs. l3.

The construction of the head portion 22 of our improved razor is particularly brought forth in Figs. 4, 6 and 9. pivotally mounted on cross arms 4% extending transversely of the spider 36. Adjacent these pivotal connections the cap sections are provided with projections 42 which engage the undersurface of the guard 28 when the spider 36 moves upwardly thereby causing the cap sections to pivot outwardly and move toward their open positon. The means for moving the spider 36 will be described in detail below. The spider 36 has the shape of an elongated bar for locating slotted blades, such as the blade B, on the head portion of the razor.

The platform 24 has upturned edges 44 which provide a plurality of lands preferably having a substantial area against which a blade may be clamped without introducing undue stress concentration therein. Also it will It will be seen that the cap sections 26 are V 4 be noted that the edges 44 are beveled to provide the correct angle of the blade B with respect to the guard surfaces 38. This platform arrangement provides a highly desirable means for mounting a blade in the head portion of a razor, particularly where relative adjustment is to be effected between the blade edge and a guard surface such as the guard surfaces 39.

In our illustrated embodiment we have found, it desirable to provide openings 4-6 in the guard member 28 through which the upturned edges 44 may pass (Fig. 4). It will be noted that the upturned edges thus are disposed adjacent the guard surfaces 3tl to provide a firm support for the blade B as it is maintained above the surface of the guard member 28 at all times. This particular arrangement is found desirable for use with our illustrated means for adjusting the shaving relation between the blade B and the guard surfaces 30.

As noted above, the guard member 28 is fixed relative to the handle 29; This may be achieved by spinning or otherwise securing a tubular guard extension 48 to said guard member (Figs. 4 and 6).

or otherwise secured an insert 56. Between the insert 56 and the collar 59 there is provided a washer 58 the function of which will be brought out below. The above construction thus provides a connection between the blade-clampingmember or platform 24 and the handle 20 in which'the finger knob 54 may be rotated to vary theheight of the blade B clamped thereon by the cap sections 26 with respect to the guard surfaces 39. Thus the shaving relation of the blade B may be varied between the illustrative extremes seen in Figs. 6 and 7. It

will be appreciated that this connection is substantiallyv rigid'due to the solid metal-to-metal contact of the ole ments between the platform 24 and the handle 26. it is well to note that this connection provides adjustment of the platform 24 with respect to a relatively fixed handle 20 and guard 28.

Other aspects of the invention are found in further constructional features of the extensible connection 32.

'Ashas been noted, this connection enables adjustment of the shaving relation of the blade B relative to the guard 28. It is preferable that the user of the razor be able to note a desiredsettingv of this connection at a favored shaving relation. It is also desirable that such setting be maintainable from blade to blade without being reset each time a new blade is put to use. Thus it will be noted that externally-visible indicia. 69 are spaced around theouter. surface of the finger knob 54 (Figs. 1 and 10). These indicia may be matchedagainst a further mark 62 found on the platform extension 52 to denote the favored setting of the connection 32. A leaf spring 64 rides within a slot 66 formed in the finger knob insert 56 (Fig. 4). This spring is thus carried with the finger knob 54 as it is rotated to adjust the connection 37.. A protruding portion 68 of the spring 64 enters longitudinally finger knob 54- is releasably maintained in an adjusted position only when one of the indicia 69 is matched against the mark 62. Preferably the indicia 60 are equally spaced around the finger knob 54. It can be seen that The lower end of this. guard extension is pressed into a collar 50 whichin turn' this construction permits the cap sections 26 to be brought into and out of clamping relation without affecting the shaving relation of the clamped blade relative to the guard 28. Furthermore, the established shaving relation cannot be readily changed through inadvertence.

Referring again to Figs. 4, 9 and 10, an integral finger 72 will be seen projecting below the main portion of the finger knob insert 56 beside the washer 58. It will now be noted that the washer 58 has integral dogs 74 which enter flutes 76 on the guard extension to prevent relative rotation therebetween. Also formed on the washer 58 is a projection 76 which extends into the path of IO- tational movement of the finger 72. In this manner rotation of the finger knob 54 is limited to slightly less than one revolution as the finger 72 encounters the projection 76 in both directions of movement. Thus the shaving relation of the blade B relative to the guard 28 may be varied only through a fixed range as illustrated in Figs. 6 and 7 and each distinctive indicia 6t) always indicates a given adjustment or setting of the shaving relation.

As indicated above, the position of the composite blade-clamping member or cap sections 26 is controlled by axial movement of the stem 34, which also may be a composite assembly. This stem assembly (Figs. 4, 5 and 8) comprises a shaft 78 fast upon the spider 36, with a stem collar member 80 threadably connected to its lower end. Threads 82 may be formed on the stem collar member 80 to provide attaching means for a coil spring 84. This spring in turn is attached by being screwed upon similar threads 86 formed on a lower stem member 88. It will be noted that the stem collar member 80 and lower member 88 respectively which are brought into abutting relation by the spring 84 when the stem assembly 34 is in a position which brings the cap sections 26 to a partially or fully open position (Fig. 8). This arrangement permits the spring 84 to be maintained under tension for reasons which will be more fully brought forth below. The lower portion of the lower stem member 88 is roughly rectangular in cross section and passes through and beyond a matching hole in a plug 94 pressed into the lower end of the handle and which in certain respects may be considered an integral part thereof. This arrangement prevents relative rotation between any of the components of the stem assembly 34 once it is assembled within the handle 20. A second coil spring 96 is provided within the handle 20 between the plug 94 and the collar member 80 urging it and the entire stem assembly 34 at all times toward a position wherein the cap sections 26 will be in their fully open position.

Axial movement of the stem assembly 34 may be controlled by manipulation of the finger-piece 38 which is pivotally connected to the lower stem member 38 by a pin 98. More precisely the lower portion of the lower stem member rides within a bifurcation 95 formed in the finger-piece 38 (Fig. 5). When the finger-piece 38 is brought into axial alignment with the handle 20 (Fig. 5) its convex upper end cooperates with a matching surface on the plug 94 to maintain this aligned position. It can readily be seen that when the stem assembly 34 is in a lower-most position, the cap sections 26 have been brought to their blade-clamping position and the blade B is securely clamped against the upturned edges of the platform 24. It Will also be noted that the clamping pressure exerted by the cap sections 26 is imparted thereto through the coil spring 84 and further that this pressure is not due to merely elongating the spring 84 the slight distance illustrated in Figs. 5 and 8, but is substantially higher due to the fact that the spring 84 is maintained under tension. 7

When it is desired to rinse the present razor, the fingerpiece 38 is pivoted in a clockwise direction (Fig. 8), the the lower stem member 88 will move upwardly under the influence of the spring 84 while the entire stem assembly preferably have stems 9t), 92

moves upwardly under the influence of the compression spring 96. This upward axial movement of the stem assembly causes the cap sections to move toward their open position. However, pivotal movement of the finger-piece 38 in a clockwise direction is limited in magnitude and thus the finger-piece will engage the handle 20 in the manner shown in Fig. 8 to limit the upward movement of the stem assembly 34 to a position wherein the cap sections are in their partially open or rinsing position. This position of the finger-piece 38 thus corresponds to the rinsing position of the razor head portion seen in Fig. 2. The rinse position of the finger-piece 38 may best be provided by forming one side of the bifurcation shallower than the other so that an edge 100 limits the pivotal movement to a separate and distinct position. It will be seen that a dot 102 or other indicia may be placed on the finger-piece 38 as a visual aid to assist the user in pivoting the finger-piece to obtain a desired position of the razor head. Since the bifurcation 95 is relatively deeper than the edge 100 on its other side when the finger-piece is pivoted in the opposite direction (counter-clockwise in Fig. 8), the spring 96 may urge the stem assembly 34-upwardly to a position in which the cap sections 26 will fully open, as seen in Fig. 3. The fully open position of the cap sections is controlled by engagement of the stem collar member 80 with the underside of the handle collar 50 and this position may be adjusted by the degree to which the stem collar member 80 is threaded onto the stem shaft 78.

It will further be appreciated that the particular stem arrangement described herein has certain inherent advantages when combined with a razor structure having means for adjusting two cooperating blade-clamping members with respect to a relatively fixed guard. Thus it will be seen that when a blade is in a clamped position its shaving relation with respect to the guard may be varied as by rotating the finger knob 56. It will be further appreciated that because of the arrangement which provides the tensioned spring 84 through which a clamp ing pressure is exerted that a minimum clamping pressure may readily be obtained when the blade edge is in its lower position without causing any substantial increase in the clamping pressure as the blade is adjusted to its higher position. In other words, the clamping pressure is obtained from a spring under tension having a relatively flat scale to give the desired initial clamping pressure; further extension thereof does not substantially increase its spring force.

Having thus described our invention, what We claim as new and desire to secure by Letters Patent of the United States is:

l. A safety razor comprising a hollow handle, a head portion disposed at one end of said handle and including a platform having upturned edges, a guard member having openings through which the upturned edges of the platform pass to maintain a blade above the surface thereof and separable cap sections relatively movable with respect to said guard member into three difierent positions, comprising a blade-clamping position wherein the blade is operatively clamped against the upturned edges of said platform for use in shaving, a partially open position in which the razor blade is loosely confined in the razor head portion for rinsing, and a fully open position for blade replacement, and a spider carrying said cap sections, a tubular extension having longitudinally-extending flutes affixed to said guard member extending coaxially of and secured to said handle, an extension aflixed to said platform surrounding the guard extension and also extending co-axially of said handle, a finger knob threaded onto said platform extension and bottoming against said handle, said finger knob being adjustable to establish a desired height of the upturned platform edges with respect to the guard member, a detent spring carried by saidprojecting portion adapted to finger knob and having a v enter the flutes in the guard extension to releasably main- .finger knob when an indicia marked thereon is in alignment with the mark providedvon the platform extension,

an axially-movable stem assembly for bringing said cap sections into the three aforementioned positions, said stem assembly comprising two. relatively movable members and a coil spring interconnecting these members under tension, said stem assembly being fastened to said spider and extending through and beyond the other end of said handle, a spring urging said stem assembly towards a position wherein said cap sections are in their fully open position, a finger-piece pivotally mounted on said stem to co-act with said other end of said handle when brought in axially alignment therewith to overcome the actionto f said spring and thereby maintain said cap sections in their blade-clamping position, and means limiting the pivotal movement of said finger-piece in one direction to a definite position wherein said spring imparts axial movements to said stem assembly, limited by further engagement of said finger-piece with said other end of said handle, to bring said cap sections to their partially open position, said finger-piece being free to pivot in the other direction a greater distance suficient to allow axial movement to be imparted to said stem by said spring to cause. the cap sections to assume their fully open position; 1

,2. A safety razor comprising a hollow handle, a head portion disposed at one end of said handle and including a guard ,and'two blade-clamping members relatively movable into three different positions comprising a bladeclamping position wherein a blade is operatively clamped therebetween for use in shaving, a partially open position in which the razor blade is loosely confined in the razor head portion for rinsing, and a fully open position for blade, replacement, a manually-adjustable extensible rigid :connection between said handle and one of said members for adjusting the setting of thelatter relative to the guard, an axially-movable stem assembly for controlling the position of the other of said members, said stem assembly comprising two relatively movable members and a coil spring'interconnecting the stern members under tension, said stem assembly connecting with one of said blade-clamping members and extending through and beyond the other end of said handle, a finger-piece pivotall'y connected to the stem assembly for imparting the aforesaid axial movement to said stem assembly to control the relation between said clamping members, and selectable means having three separate and distinct settings for limitingthe aforesaid axial movement of the stem assembly-to threepositions corresponding to the three relative positions of the blade-clamping members.

3. A safety razor comprising avhollow handle, a head portion disposed at one end of said handle and including a platform having upturned edges, a guard member having openings through which the upturned edges of the platform pass to maintain therblade above the surface thereof, and separable cap sections for clamping a razor blade against the edges of said platform in shaving relation withrespect to said guard, a tubular extension alfixed to said guard member-and secured to said handle establishing a fixed relationship therebetween, an extension afiixed to said platform concentrically of and surrounding the guard extension, a finger knob threaded onto said platform extension and bottoming against said handle, said finger knob being adjustable to establish a desired height of the platform edges with respect to the guard member, an axially-movable stem assembly for bringing said cap sections into and outof bladeeclamping relation,

said-stem assembly comprising two relatively movable members and a coil spring interconnecting the stem members under tension, said, Stem assemblyconnectingl' with said cap sections andextending through and beyond,

the other end of said handle, and a finger-piece pivotally connected torthe stem assembly for imparting the aforesaid axial movement to said stem assembly to bring'said cap sections into and out of blade-clamping relation.

4. A safety razor comprising a hollow handle, a head portion disposedat one end of said'handle and including a platform having upturnededges, a guard member having openings through which the upturned edges of the platform pass to maintain the blade above the surface of the guard member, and separable cap sections for clamping a razor blade against the edges of said platform in shaving relation with respect to said guard member, a tubular extension having longitudinally-extending flutes affixed to the guard member, extending co-axially of and secured to said handle, an extension aflixed to' said platform surrounding the guard extension and also extending co-axially of said handle, a finger knob threaded onto the platform extension and bottoming against said handle, said finger knob being adjustable to'establish a desired height of the platform edges with respect to the guard member, a detent spring carried by said finger knob and having a projecting portion adapted to enter the flutes in the guard extension to releasably maintain adjusted incremental positions of the finger knob, and manually-operable motion-transmitting means for bringing said cap sections into andtout of clamping relation with said platform, said motion-transmitting means connecting with said capsections and extending through and beyond the other end of said handle.

5. A safety razor comprising a hollow handle, a head portion disposed at one end of said handle and including a platform having upturned edges, a guard'mem-' ber having openings through which the upturned edges of the platform pass to maintain the blade above the surface of the guard member, and separablegcap sections for clamping a razor blade against the edges of said platform in shaving relation with respect to said guard member, a tubular extension afiixed to the guard member and secured to said handle establishing a fixed relationship therebetween, an extension afiixedito said platform concentrically of and surrounding said guard extension, a finger knob threaded onto said platform extension and bottoming against said handle, said finger knob being adjustable to establish adesired height of the platform edges with respect to the guard member, and manually-operable motion-transmitting means'for bringing said cap sections into and out. of blade-clamping relation with said platform, said motion-transmitting means f connectingwith said cap sections and extending through and beyond the other end of said handle.

6. A safety razor comprising a hollow handle, a head portion disposed at one end of said handle'andincluding a platform having upturned edges against which a blade mey be clamped, a guard member having openings through which the upturned edges of the platform pass to maintain the blade abovethe surfaceof the guard mem-' ber, and separable cap sections for clamping a razor blade against the edges of said platform in shaving relation with respect to said guard member, a tubular extension having longitudinally extendingflutes affixed to said guard member, extending co-axially of and secured to said handle, an extension afiixed to said platform co axially of said handle and surrounding the guard extension, a finger knob threaded onto the platform extensionand bottoming against said handle, said finger knob being adjustable to establish a desired height of the platform edges with respect to the guard member, said finger knob having indicia in spaced relationship around itsouter surface which may be matched against a mark provided on the platform extension, a detent'spring carried by said finger knob arranged to enter said flutes and thereby releasably maintain said finger knob in an adjusted position, the relationships between said indicia, mark, detent spring and flutes being such that the detent spring is effective in releasaoly maintaining said finger knob when an indicia marked thereon is in alignment with the mark provided on the platform extension, and manually-operable motion-imparting means for bringing said cap sections into and out of clamping relation with said platform, said motion-imparting means connecting with said cap sections and extending through and beyond the other end of said handle.

7. A safety razor comprising a hollow handle, a head portion disposed at one end of said handle and including a guard and two bladeclamping members between which a blade may be clamped in shaving relation with respect to said guard, a manually-adjustable extensible rigid connection between said handle and one of said members for determining the setting of the latter relative to the guard, externally-visible indicia associated with said connection for indicating selected incremental positions thereof, detent means for releasably maintaining said extensible connection at the various positions shown by the indicia, and manually-operable motiontransmitting means for bringing the other of said members into and out of blade-clamping relation, said means connecting with said last-mentioned member and extending through and beyond the other end of said handle.

8. A safety razor comprising a hollow handle, a head portion disposed at one end or" said handle and including a member against which a blade may be clamped, a pair of separable cap sections cooperating therewith to clamp a flexible blade in shaving relation and a spider carrying said cap sections, an axially-movable stem assembly for bringing said cap sections into and out of blade-clamping relation, said stern assembly being connected to said spider and extending through and beyond the other end of said handle, said stem including a shaft portion fast upon said spider, a collar stem member adjustably threaded into said shaft portion, a lower stem-member which is in abutting relationship with said collar stem member when said cap sections are out of clamping relation with the clamp member, and a coil spring interconnecting said collar stem member and said lower stem-member, said coil spring being under tension when said last-mentioned members are in abutting relationship, a second coil spring within said handle surrounding said stem and acting against said collar stem member to impart movement to said stern assembly toward a position wherein said cap sections are out of clamping position, abutment means within said handle for limiting said movement as defined by the adjustment between said collar stem member and said stem shaft, and a finger-piece pivotally connected to said stem assembly for imparting the aforesaid axial movement to said stem against the action of said second spring to control the relation between said cap sections and said clamp member.

9. A safety razor comprising a hollow handle, a head portion disposed at one end of said handle and including two blade-clamping members relatively movable into three different positions comprising a blade-clamping position wherein a blade is operatively clamped therebetween for use in shaving, a partially open position in which the razor blade is loosely confined in the razor head portion for rinsing, and a fully open position for iade replacement, an axiaily-movable stem for controilin the position of one said members, said stem connecting with said member and extending through and beyond the other end of said handle, a spring urging said stern towards a position wherein said members are in their fully open position, a finger-piece pivotally mounted on said stem to coact with said other end of said handle when brought in axial alignment therewith to overcome the action of said spring and thereby maintain said mem ers in their blade-clamping position, and means limiting the pivotal movement of said finger-piece in one dir tion to a definite position when said spring imparts axial movement to said stem, limited by further engagement of said finger-piece with said other end of said handle to bring said clamping members to their partially open position, said finger-piece being free to pivot in the other direction a greater distance suificient to allow axial movement to be imparted to said stem by said spring to cause the blade-clamping members to assume their fully open position.

10. A safety razor as described in claim 9 in which the stem enters a bifurcated portion of the finger-piece and in which the bifurcation is shallower on one side than on the other to provide means for limiting the pivotal motion of the finger-piece when thrown in said direction to cause the clamping members to assume their rinse position.

11. A safety razor having a hollow handle, a head portion disposed at one end of said handle and including two blade-clamping members relatively movable into three different positions comprising a blade-clamping position wherein a blade is operatively clamped therebetween for use in shaving, a partially open position in which the razor blade is loosely confined in the razor head portion for rinsing, and a fully open position for blade replacement, and manually-operable motion-transmitting means connecting with one of said members for controlling the position thereof, said means extending through and beyond the other end of said handle and selectable stop means connecting with said motion-transmitting means and having separate and distinct settings corresponding to the three relative positions of the clamping members.

References Cited in the file of this patent UNITED STATES PATENTS 1,755,726 Conill Apr. 22, 1930 2,312,503 Testi Mar. 2, 1943 2,369,685 Nelson Feb. 20, 1945 2,561,610 Bruneau July 24, 1951 2,644,229 Muros July 7, 1953 2,754,583 Liberatore July 17, 1956 2,769,232 Leonard Nov. 6, 1956 FOREIGN PATENTS 72,424 Denmark Apr. 16, 195