For clarity, are you talking about a shave test here? And with regard to torque, on the latter stages you don't want much. Just enough that the edge is making good contact. Maybe post a pic of the whole blade so we can see what you're up against.It is the gentlest edge I think I could imagine and it does remove hairs. It doesn't tug, but it is not grabbing the hairs fully. I know this is the keenness, the apex is not narrow enough. Maybe it is micro beveled too much beyond the visible. What I am afraid is that the razor itself isn't guiding the bevel set due to the amount of torquing I am having to do.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

To go back to the 1.5k or not, that is the question

- Thread starter APBinNCA

- Start date

- Thread starter

- #22

The entire edge does not have to undercut at the same time, just sequentially as you roll through the stroke. The whole reason that you're rolling is because the whole edge does not contact the hone at the same time.

I honestly didn't know that. However the twist this thing has, the spine has air under it from about two thirds from the tip to just before the stabiliser. If it merely lifted, I could see rolling into it. But because of the unusual shape to the twist, I can't figure out any way to get the heel to push water without torque.

I honestly didn't know that. However the twist this thing has, the spine has air under it from about two thirds from the tip to just before the stabiliser. If it merely lifted, I could see rolling into it. But because of the unusual shape to the twist, I can't figure out any way to get the heel to push water without torque.I think that I would need to have the razor in hand to understand this.I honestly didn't know that. However the twist this thing has, the spine has air under it from about two thirds from the tip to just before the stabiliser. If it merely lifted, I could see rolling into it. But because of the unusual shape to the twist, I can't figure out any way to get the heel to push water without torque.

- Thread starter

- #24

This is also very helpful. Your first paragraph pretty much describes how things went with the 1.5k. At some point after creating an almost completely new bevel, I started noticing the abrasion happening behind the apex and did everything as you said. It took quit a bit after this point because I had already joined the bevels and thought I was done and had decided to add some more laps to make sure and that's when the abrasion started going wrong. It sounds like I have a good bevel set, thumbnail test passes easily.In addition to the very good advice above, a couple thoughts on pressure and torque. I like to think of the bevel set stage as doing two things: first, establishing a relationship between the bevel and the spine, and second, developing a bevel with a good apex. Obviously they happen simultaneously but the second can't happen until the first is established. At this stage, you may need to use fairly even pressure across the bevel and spine. As it starts to come together, you can begin to lighten up your pressure and bias it toward the edge. Also the grind of the razor will limit how much you can bear down on the edge. A thin full hollow will deflect with too much pressure and you won't hit all the way to the apex. So using a little torque instead of straight down pressure is useful there.

A Sharpie will tell you if you're honing all the way to the apex, both at the 1.5k levels and further on in your progression. Also Sharpie the spine. This will show you very quickly if you're abrading both spine and bevel evenly.

I also like circles, focusing on a third of the blade at a time, especially at the early stages on each grit. Once things start to come together I will do 10 x-strokes, followed by light circles on eqch side, then more x-strokes. If you have any rough areas it's usually pretty easy to hear and feel with circle strokes.

As far as how much time to spend on the 1.5 and 5k, there's no recipe. You're done when you're done.

I need to get the sharpie out, thank you for the advice there. And the method with the circles. I am started to feel better about all this, I was afraid I was just going to get told off. Will get a picture up of the twist I am dealing with...

Another thing I might add as far as Setting the Bevel is that I tend to look at a bevel as being set when it can cut arm hair at skin level with very little contact pressure. If I feel like I’m having to push to get the hair to cut I’m inclined to do a little more work.

- Thread starter

- #26

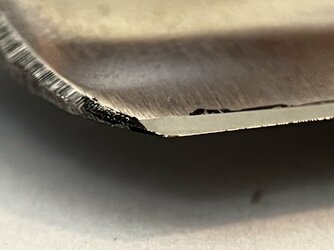

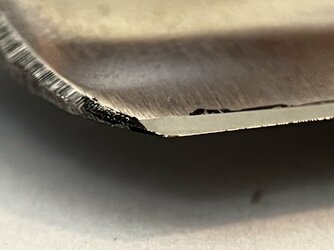

Here you can see the noodle spine. The existing bevel follows the shape of the spine, I have already straightened that out. Image before starting.

Here you can see blue under the spine where the twist is, that's light.

Here is the heel before I fixed it for context

Here is a brand new image I just took

Apologies to everybody trying to help, my internet connection was not behaving and it took me an hour to get these posted.

Here you can see blue under the spine where the twist is, that's light.

Here is the heel before I fixed it for context

Here is a brand new image I just took

Apologies to everybody trying to help, my internet connection was not behaving and it took me an hour to get these posted.

That's how I was taught to check the sharpness of a knife by the older guys when I worked in a meat processing plant. the nail test, they called it. They were a great group of guys. I was 21... and a complete novice. They taught me how to use stones effectively... taught me to file off all the roughness on a steel to make it work for the job at hand.Not sure how you did this but take the razor and try to glide it on your thumb nail. Don’t cut the nail off, do it with the nail attached. Just Google it and there are videos out there.

I had some little hollow ground knife sharpeners made up... steel handles with a piece of hollow ground carbide welded in. I'll have to take some photos. They are the same principle of those V shaped sharpeners you see out there. I have two of those. They have the carbide Vs and the ceramic finishing Vs. Well, with mine, you can set your own angle... use a bit of force in the beginning if the knife is visibly dull... and end up with just a light touch at the end at a compound angle. You can get knives razor sharp..... it really is amazing. It won't take out nicks, of course But for touch-ups, I've never found anything better or easier to use. I used to use them on my chisels, plane irons... even utility knife blades, when I did construction. I use them all the time on my kitchen knives. They even work on serrated blades because you can follow the little scallops.

Not sure how they'd do on a straight razor. The edge might not be smooth enough.

- Thread starter

- #28

Updates:

Just one round of circles and x strokes on the 5k. The ink clearly shows where the bow is in the spine, that isn't going to touch the stone. The pressure on the trouble side here is almost correct, just a little too much on the heel

The middle looks good so far

The other side, I thought I used less pressure. Nope, going to have to work on that. I think I will be able to get this corrected on the 5k by the look of it.

I was able to see this dual bevel happening previously on the 1.5k without ink. I eliminated it before moving on. I am pretty sure this tells me that I messed up on the 5k yesterday and was basically shaving with a smoothed over double bevel.

Just one round of circles and x strokes on the 5k. The ink clearly shows where the bow is in the spine, that isn't going to touch the stone. The pressure on the trouble side here is almost correct, just a little too much on the heel

The middle looks good so far

The other side, I thought I used less pressure. Nope, going to have to work on that. I think I will be able to get this corrected on the 5k by the look of it.

I was able to see this dual bevel happening previously on the 1.5k without ink. I eliminated it before moving on. I am pretty sure this tells me that I messed up on the 5k yesterday and was basically shaving with a smoothed over double bevel.

- Thread starter

- #29

I figured out where I went wrong yesterday and it's popping hairs now! I thought the problem was on the side with the bow in it, but it was the opposite side. The side that project out instead of in, where I kept banging the side of the stone. It turns out that the bevel lines up with the spine on this side so long as the spine area above the stabiliser is on the stone. It's almost impossible to ramp up onto it, that's why it kept crashing. I did grind it down it down with my lapping plate, but it is still too much material and everything works if I stay on top of it. I have mostly stopped torquing it too, opting to roll instead. So I devised some different stroke and finally like what I am seeing in the microscope. I probably did 50 more light laps than I needed to, but I wanted to make sure it's smoothed out. Onto the next stage...

Ok, a lot going on with the razor and technique. Bottom line, the bevel is/was not fully set.

Some better photos of the whole razor on both sides as clear as you can get them, will help advise you. The razor had heel issues, clearly it has been honed on the stabilizer which kept half of the razor off the stone.

You rounded the heel, but the heel corner could still be moved farther away from the stabilizer at least a ¼ inch, or you may be honing on the stabilizer again, compounding the damage to the razor. Clearly the heel is not on the stone, and you must find out why.

Use a coin, Quarter or Nickle to trace an arc that will do than and remove steel to the line, a diamond plate will make quick work of that.

Now ink the bevels fully and the spine all the way to the tang and ink the stabilizers. Do one lite lap on your slate and now you will see exactly where you are making contact. Just one lap. Take another set of photos. WD40 will remove all the ink easily when you are through.

Set the bevel fully, from heel to toe, on the 1.5k with a rolling X stroke. Look straight down on the edge, when all shiny reflections are removed from the edge, the bevel is fully set. Do not move up in grits until the bevels are meeting from heel to toe. Your heel is not honed, appears to not be touching the stone.

Keep honing simple, on synthetics only, the slate will only add variables at this stage of learning. Remove the 1.5k stria with the 5k, remove all the1.5k stria without damaging the edge. Again, look straight down on the edge to confirm no chips.

Remove each previous grit with the following grit and keep looking down on the spine to ensure you have not damaged the bevel set.

So, you have 2 issues, 1. You the razor needs repair, Ink on the spine and bevels will tell you what is needed. (Your heel is a known issue)

2. You do not have a foolproof method of determining a fully set bevel, hair tests are unreliable until calibrated. What ever your test is, ensure that the edge is FULLY set after each stage in the progression, that you are honing to the edge and the previous grits stria has been fully removed.

Do not torque the razor, you may be flexing the blade and lifting the edge off the stone. Do not count laps, you do as many laps as it takes to fully set the bevel, and as many as it takes to remove the previous grits stria with each progression, without damaging the bevel set.

Any razor can be easily honed with a rolling X stroke.

Again, photos of the complete razor from both sides will help in advising you.

Some better photos of the whole razor on both sides as clear as you can get them, will help advise you. The razor had heel issues, clearly it has been honed on the stabilizer which kept half of the razor off the stone.

You rounded the heel, but the heel corner could still be moved farther away from the stabilizer at least a ¼ inch, or you may be honing on the stabilizer again, compounding the damage to the razor. Clearly the heel is not on the stone, and you must find out why.

Use a coin, Quarter or Nickle to trace an arc that will do than and remove steel to the line, a diamond plate will make quick work of that.

Now ink the bevels fully and the spine all the way to the tang and ink the stabilizers. Do one lite lap on your slate and now you will see exactly where you are making contact. Just one lap. Take another set of photos. WD40 will remove all the ink easily when you are through.

Set the bevel fully, from heel to toe, on the 1.5k with a rolling X stroke. Look straight down on the edge, when all shiny reflections are removed from the edge, the bevel is fully set. Do not move up in grits until the bevels are meeting from heel to toe. Your heel is not honed, appears to not be touching the stone.

Keep honing simple, on synthetics only, the slate will only add variables at this stage of learning. Remove the 1.5k stria with the 5k, remove all the1.5k stria without damaging the edge. Again, look straight down on the edge to confirm no chips.

Remove each previous grit with the following grit and keep looking down on the spine to ensure you have not damaged the bevel set.

So, you have 2 issues, 1. You the razor needs repair, Ink on the spine and bevels will tell you what is needed. (Your heel is a known issue)

2. You do not have a foolproof method of determining a fully set bevel, hair tests are unreliable until calibrated. What ever your test is, ensure that the edge is FULLY set after each stage in the progression, that you are honing to the edge and the previous grits stria has been fully removed.

Do not torque the razor, you may be flexing the blade and lifting the edge off the stone. Do not count laps, you do as many laps as it takes to fully set the bevel, and as many as it takes to remove the previous grits stria with each progression, without damaging the bevel set.

Any razor can be easily honed with a rolling X stroke.

Again, photos of the complete razor from both sides will help in advising you.

Your heel is not fixed, it needs to be ground forward towards the toe in order to get the stabilizer above the heel off of the stone while the edge is fully contacting the stone surface without undue pressure. The edge at the heel now is headed towards a hook, not what you want.

There is some archived content on this site about how to correct heel-stabilizer problems.

There is some archived content on this site about how to correct heel-stabilizer problems.

- Thread starter

- #32

Light bulb, thank guys! It's a good thing this razor was a previous users project. I had been making good progress with easier razors and thought I will just figure this out somehow. I already have the razor "fixed" right now and am planning to shave with it before I have to re-do the whole thing over again. I will try to get pictures of the finished product before I work on the heel. It's really strange banging by head against the wall knowing that I am not doing something really wrong, but not understanding what the razor is telling me. Why am I banging the stabiliser, it's making honing so difficult. Obviously, it wasn't obvious. I thought it was just the twist. I won't be doing any more this bad for a while. Stay tuned for pictures...

I'm not exactly sure what you mean by "joined the bevels." Are you still doing a bunch of work on one side at a time like you described on an earlier thread?It took quit a bit after this point because I had already joined the bevels

- Thread starter

- #34

No, I decided against that. I shined a light on the edge to check for reflections and then the microscope to double check. I just meant that I had done enough laps that I was pretty sure I had an apex. I had bread knifed some of the edge prior.I'm not exactly sure what you mean by "joined the bevels." Are you still doing a bunch of work on one side at a time like you described on an earlier thread?

:banghead: <eg>

Boo hiss... those don't work here. You have your hands full.... but you are getting there.

Boo hiss... those don't work here. You have your hands full.... but you are getting there.

- Thread starter

- #36

Okay now we are in business! This little French rock is amazing. I read everything that you all have shared multiple times, IT IS GREATLY APPRECIATED. I am hard headed at times, but I am not incompetent nor unable to learn.

I went to the La Lune and didn't count laps. I focused on staying off the stabiliser and getting good rolling X strokes. I inked the bevel and the spine. The La Lune told me before I even checked visually that I should go back to the 5k once I had consistent X strokes, but I did not. I kept at it and after about thirty minutes I had it. Things started getting faster and lighter toward the end and the bevel was pushing water without any torquing.

I did laps on denim and many laps on leather. I was going for that magnetic draw, it took time. I got there and the shave proved it. Sure the heel needs to be re-done, but I am using this razor for the next week. Hopefully I can re-profile the heel without having to fully reset everything. I am going to try to only hone as much of the edge as I have to to integrate it with my existing bevels.

What a learning experience!

I went to the La Lune and didn't count laps. I focused on staying off the stabiliser and getting good rolling X strokes. I inked the bevel and the spine. The La Lune told me before I even checked visually that I should go back to the 5k once I had consistent X strokes, but I did not. I kept at it and after about thirty minutes I had it. Things started getting faster and lighter toward the end and the bevel was pushing water without any torquing.

I did laps on denim and many laps on leather. I was going for that magnetic draw, it took time. I got there and the shave proved it. Sure the heel needs to be re-done, but I am using this razor for the next week. Hopefully I can re-profile the heel without having to fully reset everything. I am going to try to only hone as much of the edge as I have to to integrate it with my existing bevels.

What a learning experience!

I would like to clarify my use of the word torque. You need to apply pressure to the spine and the edge or you won't remove any metal. How much pressure? Enough to remove the desired amount of metal from the spine and edge - which varies by razor.

From my experience, I normally need to apply more pressure to the edge than the spine. Rightly or wrongly, I use the word torque to describe this. How much torque? Again, enough to remove the desired amount of metal. If you apply too much torque, you will bend/flex the edge around a line parallel to the edge and end up with a bevel wider than needed.

From my experience, I normally need to apply more pressure to the edge than the spine. Rightly or wrongly, I use the word torque to describe this. How much torque? Again, enough to remove the desired amount of metal. If you apply too much torque, you will bend/flex the edge around a line parallel to the edge and end up with a bevel wider than needed.

Likely you will need to reset the bevel again especially if you correct/ reshape the heel.

If the heel is wonky and needs reprofiling, it was keeping half of the edge off the stone, as one of your photos demonstrates, and putting more pressure/wear on the toe half of the blade as you tried to force the heel onto the stone.

So, half of the blade is worn excessively and the other half minimally or not at all. I doubt the whole edge is actually shaving. It is not massively wonky but enough that the whole edge is not on the stone and in the same plane.

The good news is you are probably really close. Once you can get the blade flat on the hone, the 1.5k will easily fully set the bevel, then it is just a matter of running up the grits and removing each of the previous grits stria to straighten the edge.

Your edge will not get really straight until after an 8k stone. I doubt your slate is 8k. So go to film, you should be able to get a smoking edge with 1um film and a great shaving edge with 1um and paper. Chrome Oxide or CBN will refine it even further.

Introducing an unknow grit slate with slurry is just adding more variables at this point. Get a repeatable smoking edge off of film, then introduce naturals, you may find that you are going backwards. There are no magic stones...

You are close, just slow down and keep it simple. The only way to learn how to hone is to hone, but doing the same thing and expecting a different result is not the answer. If it is not working, stop and figure out why.

If the heel is wonky and needs reprofiling, it was keeping half of the edge off the stone, as one of your photos demonstrates, and putting more pressure/wear on the toe half of the blade as you tried to force the heel onto the stone.

So, half of the blade is worn excessively and the other half minimally or not at all. I doubt the whole edge is actually shaving. It is not massively wonky but enough that the whole edge is not on the stone and in the same plane.

The good news is you are probably really close. Once you can get the blade flat on the hone, the 1.5k will easily fully set the bevel, then it is just a matter of running up the grits and removing each of the previous grits stria to straighten the edge.

Your edge will not get really straight until after an 8k stone. I doubt your slate is 8k. So go to film, you should be able to get a smoking edge with 1um film and a great shaving edge with 1um and paper. Chrome Oxide or CBN will refine it even further.

Introducing an unknow grit slate with slurry is just adding more variables at this point. Get a repeatable smoking edge off of film, then introduce naturals, you may find that you are going backwards. There are no magic stones...

You are close, just slow down and keep it simple. The only way to learn how to hone is to hone, but doing the same thing and expecting a different result is not the answer. If it is not working, stop and figure out why.

There's nothing wrong with spending a lot of time on mid-range. I have put in more time on 3k and 5k stones than a lot of people spend on their bevel setter. Done is done, not done is not done, time and lap counts mean nothing where done-ness is concerned. I actually 'kill it' on 3k and 5k stones.

Honing past 'the point' on a 5k can bring up a burr, but you should be able to notice that and get rid of it with x-strokes.

I've not found cutting fruit to be beneficial when determining bevel-set. Tests in general are fairly limited in what they can tell you actually. Dragging the blade through a nail, assuming it grabs the nail correctly in the first place, can tell you if you have an even grind from stem to stern. But you can pass any test with a blade that won't shave how you want it to.

Bevels on wonky beat-up razors can be a difficult thing. First you have to find the bevel, then you have to make it work. If you can't manage a shave when you think bevel-set is done, then it's not done. No, it won't be a BBS world class event. But it should shave. When it does shave, try to remember how it felt when honing it on the bevel-setter - because that's the ticket to ongoing consistency.

A lot of times, with some hellish razors, good steel is elusive and grinding away is the only way to find it. If a lot of dimension has been honed away already, there can be difficulty. Honing the heck out of a full hollow can lead to excessive pressure that causes the bevel to deflect.

Checking stones for flatness can help defeat hurdles too.

Most razors have curvature to the edge, like a smile or whatever. That curve should be like something drawn with a 'French Curve', without any waves along the path. only mentioning that because I just did a bit of troubleshooting for someone and that was the culprit..photos sometimes show what looks to be that but it is just lens distortion, and or doesn't show it when it is there. Kinda gotta really have a good eye to pickup a slight deviation from the 'line', but learning to see is a good part of the landscape.

Honing past 'the point' on a 5k can bring up a burr, but you should be able to notice that and get rid of it with x-strokes.

I've not found cutting fruit to be beneficial when determining bevel-set. Tests in general are fairly limited in what they can tell you actually. Dragging the blade through a nail, assuming it grabs the nail correctly in the first place, can tell you if you have an even grind from stem to stern. But you can pass any test with a blade that won't shave how you want it to.

Bevels on wonky beat-up razors can be a difficult thing. First you have to find the bevel, then you have to make it work. If you can't manage a shave when you think bevel-set is done, then it's not done. No, it won't be a BBS world class event. But it should shave. When it does shave, try to remember how it felt when honing it on the bevel-setter - because that's the ticket to ongoing consistency.

A lot of times, with some hellish razors, good steel is elusive and grinding away is the only way to find it. If a lot of dimension has been honed away already, there can be difficulty. Honing the heck out of a full hollow can lead to excessive pressure that causes the bevel to deflect.

Checking stones for flatness can help defeat hurdles too.

Most razors have curvature to the edge, like a smile or whatever. That curve should be like something drawn with a 'French Curve', without any waves along the path. only mentioning that because I just did a bit of troubleshooting for someone and that was the culprit..photos sometimes show what looks to be that but it is just lens distortion, and or doesn't show it when it is there. Kinda gotta really have a good eye to pickup a slight deviation from the 'line', but learning to see is a good part of the landscape.

There's nothing wrong with spending a lot of time on mid-range.

Ah, good to hear an expert say that. Here I've assumed I am among people who get it perfect on the bevel setter, and everything else is a couple of superficial passes.

That's not how it works for me. I can get it really wonderful on the bevel-setter, shave-worthy (yes, I've tried that shave), but still find that I need to do significant work as I go up the grits. I like to think of it as like magnification (or higher energies in particle colliders, if that resonates). The more fine-grained your measuring, the more subtly you can examine things.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 35

- Views

- 2K

- Replies

- 19

- Views

- 1K