- Thread starter

- #1,121

Tool & Die makers use a product called Prussian Blue to coat the mating surfaces. When the parts are separated the Prussian Blue sticks to the surfaces that did not mate, the mating surfaces are left shiny revealing the actual contact point. Luthiers use carbon paper to check the fit of guitar necks.Its also difficult to tell because of reflections. If you want to try something Doug, you might lay a piece of tape on the inside half of each bearing surface of the cap.

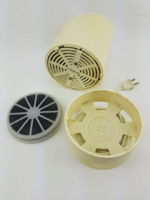

I just found the phone # of the guy that certified our Optical Comparators at work. I'm gonna check with him to see if he has an old one laying around for a cheap price.