I'd be happy to send you the stl but I just discovered that when I sized the tube and lid I was using a stick that that had worn down from use. Consequently a new full size stick won't allow the cap to go on. I wish I'd used parametric parameters in the design so that it would be easy to change but alas, I didn't. Also in a reply below "luvmysuper" asked if I thought all the open space would dry the soap out too much. That was not something I thought about but may be a real issue.^that's clever, useful too. Is thare a place where I can get the .stl file?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The great 3D Printing thread

- Thread starter luvmysuper

- Start date

- Thread starter

- #162

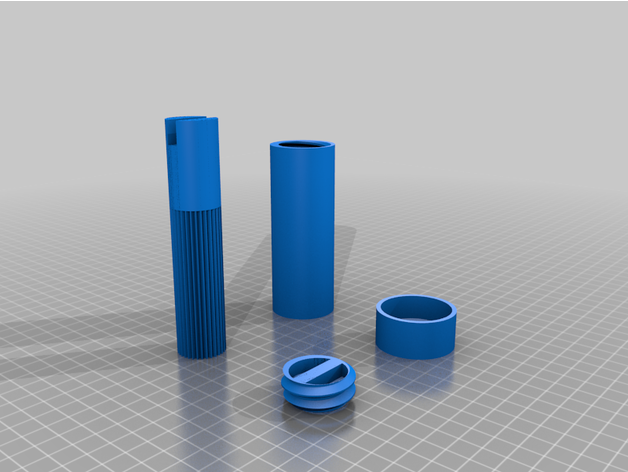

Resizing the tube lengthwise is a piece of cake.I'd be happy to send you the stl but I just discovered that when I sized the tube and lid I was using a stick that that had worn down from use. Consequently a new full size stick won't allow the cap to go on. I wish I'd used parametric parameters in the design so that it would be easy to change but alas, I didn't. Also in a reply below "luvmysuper" asked if I thought all the open space would dry the soap out too much. That was not something I thought about but may be a real issue.

If you upload to thingiverse, they can host the file, and you can just drop a link here.

I like the design, looks like it should work pretty well.I like using the Speick Soap Stick for travel lathering but have always hated the mess. I built this prototype stick holder and printed one. I did not want to use a screw mechanism to move the soap up as it requires you to drill into the soap. So I came up with this slot-tab as a way to advance the soap. I am wondering if anyone has suggestions for a more elegant method of advancing the soap? Keep in mind that my Fussion 360 skill set consists of point, click, cuss, and undo.

I am not sure this suggestion is an improvement or not, but rather than having straight horizontal lines to hold the bottom plate which in turn supports the shave stick, I might add a small indentations or step down so that the plate is less likely to move around after being adjusted. Like how in the current drawing when the stick is new or at maximum length the bottom plate can sit in the lower indentation and be more or less locked into place. But there is no similar indentation for when the stick becomes shorter and shorter. A mod something like the blue line:

I like that screw up design! Going to try it out. I'm wondering about making a slotted fitting or something for the screw head so that I could just use a knife or screwdriver and not have to carry the special wrench.You're design is actually quite good. Do you think due to exposure to air that the stick might dry out too much?

It's tough to come up with a design that doesn't require a hole in the stick, or isn't extremely messy.

Earlier in this thread I made 3 stick holders, one a traditional push up type, one a rod push up type, and the other is a screw up type that uses a fitted "handle" to reach in and screw the tube up.

I did not test print the traditional or the handle screw up type, so some twealing might be necessary.

Again, with this one, the inner screw base raises the stick up in the tube, and you use the slotted handle to reach in, engage and turn the screw up base.

Screw Tube shave stick holder by Squid3958

Another shaving stick holder for shaving soap sticks that eliminates the need to poke a hole in the center of your shave stick for it to fit in commercially available tubes. This utilizes an included tool to screw a plug up from the bottom to push the shave stick up. This is uploaded to allow...www.thingiverse.com

View attachment 1366832

I was able to put it up on Thingiverse. It may need some tweaking but by and large ok. https://www.thingiverse.com/thing:5144701^that's clever, useful too. Is thare a place where I can get the .stl file?

Thank you!I like that screw up design! Going to try it out. I'm wondering about making a slotted fitting or something for the screw head so that I could just use a knife or screwdriver and not have to carry the special wrench.

I was able to put it up on Thingiverse. It may need some tweaking but by and large ok. https://www.thingiverse.com/thing:5144701

edit: For some reason the thingiverse link isn't working.

Just testing another 3d printed razor. I've been meaning to finalize this design for quite some time now. This one's just a test print. I still need to fine-tune the geometry quite a bit more, but the first test shave was absolutely fantastic.

I'm not sure why that is. Let's try that again - GEM Single Edge Safety Razor "ENDGEM SPEED" enders style by rogerquin - https://www.thingiverse.com/thing:4689575Thank you!

edit: For some reason the thingiverse link isn't working.

This is not a shaving item. But it does get used in the bathroom. I am sharing this one because it was quite an educational exercise on the configuration of supports. It is a toothpaste wringer. And it works spectacularly well. As you can see, it has wringed every last droplet of toothpaste out of that tube in the pic. Anyways, note the integrated spring on the left side of the device. The spring holds a cam lock against the main body, which in turn provides the ratchet action that prevents the toothpaste from unwinding. Its a very effective system. But that spring is printed in place on the unit that contains the shaft and the knob. There are only three pieces. The main body, the shaft/knob/spring unit, and the end clip. Thats it. The first time I printed it with standard support settings, it was a bear to get them out. Almost impossible. But I did it anyway. So i did my research and did some testing. I was able to learn about how to configure supports, and now I can easily pull out the supports with a tweezers. Also, I have had to enlarge this model by several percents to fit the larger tubes of toothpaste. This one is about 110% if i remember correctly. This model is available on thingiverse. It is not mine. But i thought it worthy of sharing. Enjoy.

www.thingiverse.com

www.thingiverse.com

Toothpaste Wringer by kainezq

A ratcheting toothpaste/tube wringer that has a durable and easy unwinding coil spring based ratchet. You can lift up the outer ring of the turnkey to release the ratchet and remove whatever you have in there.

3D SOTD

Just testing a DE version of my previous post. This one uses halved DE blades and also has multiple plates with different efficiency. The next version will be for injector blades. At some point, I'll have all three complete and if they're not too much of a hassle to print, I'll add them to my Thingiverse page.

Just testing a DE version of my previous post. This one uses halved DE blades and also has multiple plates with different efficiency. The next version will be for injector blades. At some point, I'll have all three complete and if they're not too much of a hassle to print, I'll add them to my Thingiverse page.

Are you sure? There are shaving creams like the Palmolive one, comes in the same, toothpaste-like tube... should this work well with thoseThis is not a shaving item.

the mug is clearly FDM but the razor? SLA?3D SOTD

Just testing a DE version of my previous post. This one uses halved DE blades and also has multiple plates with different efficiency. The next version will be for injector blades. At some point, I'll have all three complete and if they're not too much of a hassle to print, I'll add them to my Thingiverse page.

View attachment 1395739

Are you sure? There are shaving creams like the Palmolive one, comes in the same, toothpaste-like tube... should this work well with those

You are right. I stand corrected. Great point. Proraso and Godrej creams too.

- Thread starter

- #173

In fairness, you don't warrant correction.You are right. I stand corrected. Great point. Proraso and Godrej creams too.

You made it for toothpaste, so it wasn't a shaving item.

One could use it for a shaving item, but that's not why you built it.

Technically I didn’t build it. I downloaded it.In fairness, you don't warrant correction.

You made it for toothpaste, so it wasn't a shaving item.

One could use it for a shaving item, but that's not why you built it.

Anyways the point was that it could indeed be a shaving item. And I agree. I just don’t enjoy shaving creams at all. But I have a bunch from over the years. This could be very useful as a shaving cream tube squeezer.

- Thread starter

- #175

Same here. It's a rare thing to find me using a cream (since they killed the old Nivea), but I could see that working with a tube of Godrej or Old Spice cream.Technically I didn’t build it. I downloaded it..

Anyways the point was that it could indeed be a shaving item. And I agree. I just don’t enjoy shaving creams at all. But I have a bunch from over the years. This could be very useful as a shaving cream tube squeezer.

The lather bowl and razor are printed with PLA. SLA would be nice for sure.the mug is clearly FDM but the razor? SLA?

but, but, did you print the razor on an FDM machine? seems like a resin thing. or did you do some form of post-processing?

or maybe it's just the picture now showing the layer lines?

or maybe it's just the picture now showing the layer lines?

It was printed on an FDM machine at a high resolution. It's hard to see the layers in the picture. PLA was my intended material since the shaft needs to flex thru the head and handle and out the bottom for the knob to screw on.but, but, did you print the razor on an FDM machine? seems like a resin thing. or did you do some form of post-processing?

or maybe it's just the picture now showing the layer lines?

Half DE and AC versions pictured below are near final. The injector version is going to take some time.

Would you upload them to thingiverse please?

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 5

- Views

- 938