So I wanted to try a gold dollar again after many years (tried a 66, 208, and 80 many years back and I believe I've only kept the 80).

Looking at prices, best deal to my eyes (if you don't plan to start selling them) was aliexpress where you could get them in quantities of 5 for ~20-25$ shipped. So I snagged five of the 66's to see if they've improved as much as I'd heard.

First things to report.

I remember my first gold dollars (8+ yrs back) having VERY flimsy scales. They were thin, weak plastic. I could open the razor, hold it by the toe end of the scales and the weight of the razor actually BENT the scales over at the middle. This was my major complaint about them. The scales were useless.

These appear to have been upgraded significantly. Plastic is much sturdier, has a middle joint (a faux "third pin"), and while I'd still consider them a bit too fat in the hand (not too much of a problem in the shave, but can make stropping feel a bit awkward)... they're definitely improved.

My package was a loose bag with the five boxed razors inside. Arrived in less than a month. Boxes were crushed, but these are pretty hearty razors. No 100 yr old ivory to break here... so I doubt I'll see any damage. Razors were heavily oiled and in plastic sleeves within their cardboard boxes.

I opened the first and it was sharp enough to open the other four, also it shaved arm hair acceptably well (seems a fairly decent bevel toe to heel).

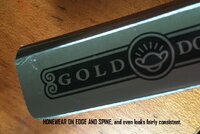

This is a MASSIVE upgrade over the past, when they were ground to ~60grit finish on a wheel and not actually beveled at the correct angle. These razors have a tiny bit of spine-wear and clearly were honed PROPERLY and beveled.

This is huge, like RIDICULOUSLY huge. Beveling the Gold dollars was the primary challenge and reason a beginner may not want to start razor honing with a gold dollar despite their price.

Can someone else confirm if this is normal for 66's now or if maybe my vendor did this work?

Have not hit the hones yet to compare if the grinding is improved, and the heel does look a bit over-fat to my eyes at first glance... but already I can tell these are massively more user-friendly to get to shave ready than they were in the past, and I'm very impressed for a $5 razor. It's looking like these can be edged even without significant grinding/geometry fixing... and if that's the case, my hats off to Gold Dollar for fixing the main drawback of these razors.

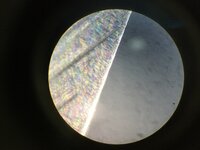

Scope shot is the edge (as received) at 400x optical magnification. Looks at least 800grit. A Decade ago these were coming @ 60grit off an abrasive WHEEL (not beveled).

Just checked all 5 edges with armhair test.

2x feel actually WELL beveled

1x beveled but a lil laggy in blade middle, probably could go right to a mid-range hone but may need a brief tuneup on a beveler.

2x have dead spots in middle so will need to hit a beveler.

Looking at prices, best deal to my eyes (if you don't plan to start selling them) was aliexpress where you could get them in quantities of 5 for ~20-25$ shipped. So I snagged five of the 66's to see if they've improved as much as I'd heard.

First things to report.

I remember my first gold dollars (8+ yrs back) having VERY flimsy scales. They were thin, weak plastic. I could open the razor, hold it by the toe end of the scales and the weight of the razor actually BENT the scales over at the middle. This was my major complaint about them. The scales were useless.

These appear to have been upgraded significantly. Plastic is much sturdier, has a middle joint (a faux "third pin"), and while I'd still consider them a bit too fat in the hand (not too much of a problem in the shave, but can make stropping feel a bit awkward)... they're definitely improved.

My package was a loose bag with the five boxed razors inside. Arrived in less than a month. Boxes were crushed, but these are pretty hearty razors. No 100 yr old ivory to break here... so I doubt I'll see any damage. Razors were heavily oiled and in plastic sleeves within their cardboard boxes.

I opened the first and it was sharp enough to open the other four, also it shaved arm hair acceptably well (seems a fairly decent bevel toe to heel).

This is a MASSIVE upgrade over the past, when they were ground to ~60grit finish on a wheel and not actually beveled at the correct angle. These razors have a tiny bit of spine-wear and clearly were honed PROPERLY and beveled.

This is huge, like RIDICULOUSLY huge. Beveling the Gold dollars was the primary challenge and reason a beginner may not want to start razor honing with a gold dollar despite their price.

Can someone else confirm if this is normal for 66's now or if maybe my vendor did this work?

Have not hit the hones yet to compare if the grinding is improved, and the heel does look a bit over-fat to my eyes at first glance... but already I can tell these are massively more user-friendly to get to shave ready than they were in the past, and I'm very impressed for a $5 razor. It's looking like these can be edged even without significant grinding/geometry fixing... and if that's the case, my hats off to Gold Dollar for fixing the main drawback of these razors.

Scope shot is the edge (as received) at 400x optical magnification. Looks at least 800grit. A Decade ago these were coming @ 60grit off an abrasive WHEEL (not beveled).

Just checked all 5 edges with armhair test.

2x feel actually WELL beveled

1x beveled but a lil laggy in blade middle, probably could go right to a mid-range hone but may need a brief tuneup on a beveler.

2x have dead spots in middle so will need to hit a beveler.

Attachments

Last edited: