Hi Frank!

Thanks for the suggested question, I will promptly send them an email enquiring. Also, what do you mean by “near wedges”

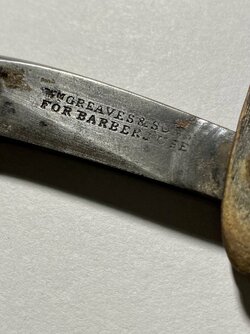

This is the photo of the grind of your razor from GSG. The ability of razor makers to grind edges has evolved over time. In the middle of the 19th century it was common to grind a razor such that it resembled a triangle with a small amount of metal ground out. This is called near wedge or quarter hollow.

As we move into the 20th century, it became common to grind away more metal. There have been numerous discussions about true wedges, near wedges/quarter hollows, half hollows and full hollows.

Here is the grind of a Filarmonica 13 Doble Temple with a full hollow grind. Different, right?

There is no better or worse, just different. All depends on what you like. I seem to have developed a preference for thicker grinds: near wedges/quarter hollows and half hollows. But I also have full hollows that I enjoy.

After you use your near wedge for while, get yourself a full hollow to experience the other side of the spectrum.

A great way to learn about different razors is to watch these two threads - just push click on the "Watch" link at the top of each:

Straight Razor Acquisition Thread

Okay, so I'm definitely not being original on this, totally taking Bigfoot's idea, but I love looking at the Safety Razor Acquisition Thread on the DE Subforum and I haven't been able to find one for straight razors. I'd love to see any Straights you've recently acquired (Pictures are a must)...

www.badgerandblade.com

www.badgerandblade.com

How straight should your straight razor be?

I'm pretty new to the straight razor game and bought my first razor recently. A question I have is how straight the blade should be compared to the scales? When I close it down, the tip is off to one side (pic below). I don't know whether this is considered acceptable and if I'm just being too...

www.badgerandblade.com

www.badgerandblade.com