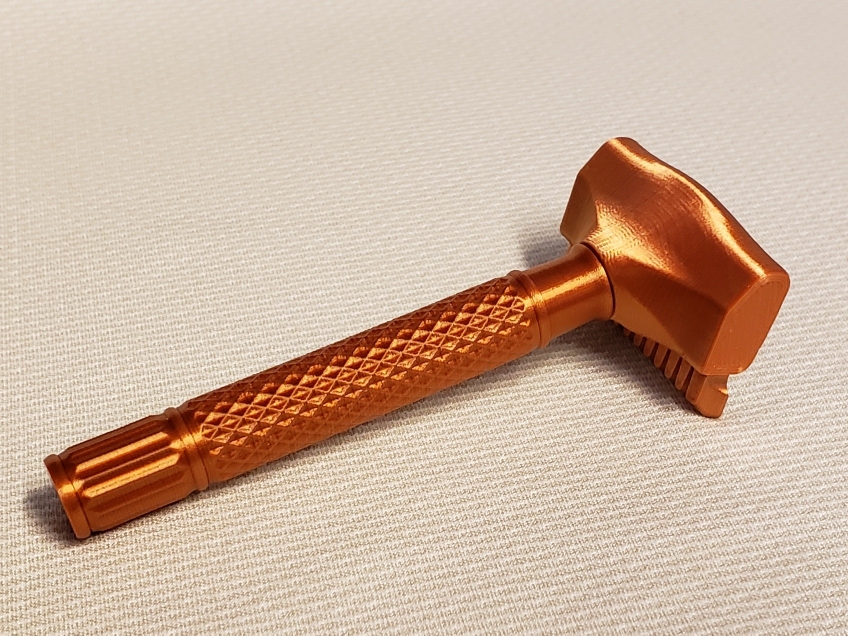

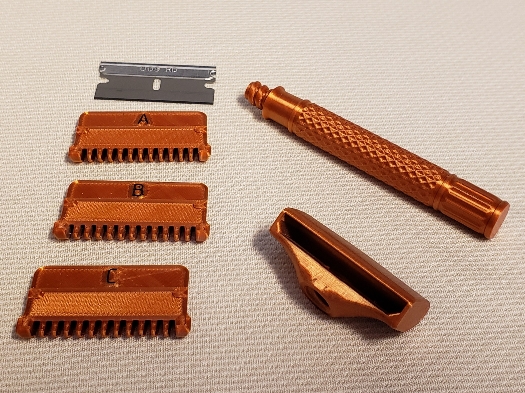

FDM 3D printers in many ways are still more of a prototyping tool. In regards to razors, if the end result is suppose to mimic traditional designs and be usable at the same time, 3D printing will have it's limitations. But then again, we're comparing plastic to metal. Great job on your project. I like the minimal approach.Anyone familiar with 3D printers and thingiverse? This is a razor on the site. I saw 2 and quit looking. Anyway, you download the file off thingiverse onto a thumb drive, stick it in the 3D printer, hit print. And there is about anything you could imagine on there. We have only been playing with 3D printing for a few years, and I believe it has printed more personal projects than work related, but hey.... its good practice LOL. Anyway, perhaps I should try printing one also???

Sent from my SM-G960U using Tapatalk