Well ok. India stones are made in a mould flat, so yes, if you have one of them convexed it would have been done manually by the owner, and it would have been a mega pain to do, i'd imagine. I can't think how they would even go about it.The stones I'm talking about which I've had like this are 110% definitely and without a doubt; intentionally convexed on one side, and they've definitely also been used on that side.

Moot have been old synths as well. And trying to flatten an India stone on loose sand would be an exercise in Sisyphean futility!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post your local/flea market stone scores. (There's none left. Tim found them all.)

- Thread starter eKretz

- Start date

Well ok. India stones are made in a mould flat, so yes, if you have one of them convexed it would have been done manually by the owner, and it would have been a mega pain to do, i'd imagine.

Here we go, I’ve just dug out an old picture of a Med India stone I got from the daughter of a guy who was apparently massively into woodworking (and then passed away).

This is one of the more extreme examples I’ve had tbf. But it’s like a banana… there must be some reason?!

Looks like a 7” was made and two different labels.Ah right, mine above is actually a bit smaller. More like a 7x2”.

I like the emu one. Make a cool T-shirt or something.

I don’t think the wear is intentional, but different tools were honed differently. While knives and plane blades were honed length wise, chisels were often honed across the short width in alternating pattern starting at the edges and worked in to the middle. As the stone wore, you might hone from one end in, then switch to the other end to keep the edge straight and bevel even. Folks were just more practical, when simple worked.

The figure 8 was also a popular honing stroke especially to camber a wide plane blade so the corners would not dig it or leave a pattern. The figure 8 would naturally put more pressure on the corners of the blade as it looped the ends of the stone.

One could add pressure on the ends or the middle of the stone depending on the type of blade being honed and it’s use, (finisher vs scrub, hogging off material) and how the blade was wearing and where correction was needed. Scrub planes take a beating.

Hand tool use required frequent honing throughout the workday, so stones got a workout.

On my Arks I generally finish each side differently and use one as a pre finisher, the other as a finisher. My stones get no where near the use and wear one would in a production shop in the day.

As long as the stones were producing good edges, they kept using and abusing them. I doubt flatness was ever an issue and folks did not bother or measure “bevel angles”.

Most hand tool woodworkers today free hand hone, to save time. Couldn’t tell you what their bevel angle is on any tool or bothered by concavity or convexity of a hone or bevel.

If it chips, hone a little steeper… much like knives.

The figure 8 was also a popular honing stroke especially to camber a wide plane blade so the corners would not dig it or leave a pattern. The figure 8 would naturally put more pressure on the corners of the blade as it looped the ends of the stone.

One could add pressure on the ends or the middle of the stone depending on the type of blade being honed and it’s use, (finisher vs scrub, hogging off material) and how the blade was wearing and where correction was needed. Scrub planes take a beating.

Hand tool use required frequent honing throughout the workday, so stones got a workout.

On my Arks I generally finish each side differently and use one as a pre finisher, the other as a finisher. My stones get no where near the use and wear one would in a production shop in the day.

As long as the stones were producing good edges, they kept using and abusing them. I doubt flatness was ever an issue and folks did not bother or measure “bevel angles”.

Most hand tool woodworkers today free hand hone, to save time. Couldn’t tell you what their bevel angle is on any tool or bothered by concavity or convexity of a hone or bevel.

If it chips, hone a little steeper… much like knives.

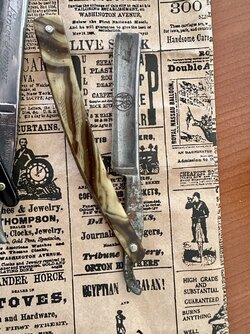

Lancet Temper? on the H B.oker? What is that? Cant find a single thing. One of many I need help identifying.

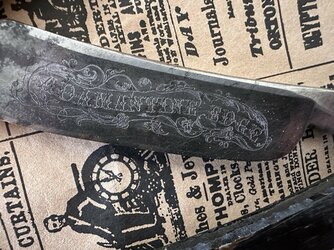

The Sheffield one is beautiful but chipped. Can't read the entire engraving on the blade.

Spent about $40 for the both of them (altogether)

The Sheffield one is beautiful but chipped. Can't read the entire engraving on the blade.

Spent about $40 for the both of them (altogether)

Attachments

Similar threads

- Replies

- 8

- Views

- 2K

- Replies

- 19

- Views

- 3K

- Replies

- 21

- Views

- 5K

- Replies

- 83

- Views

- 11K