This is apparently being touted as a replacement for the Hard Arkansas:

Anybody tried one...?

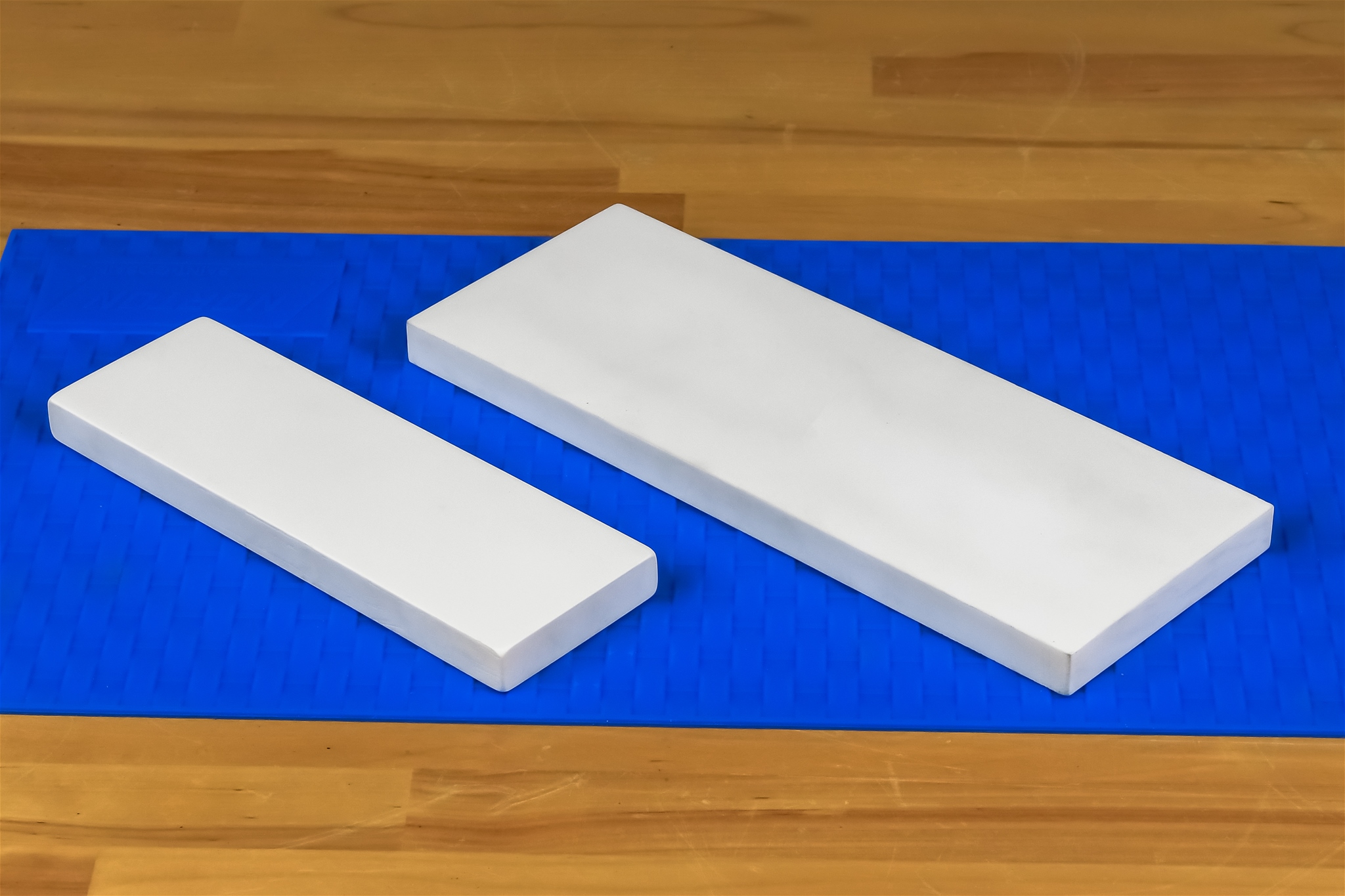

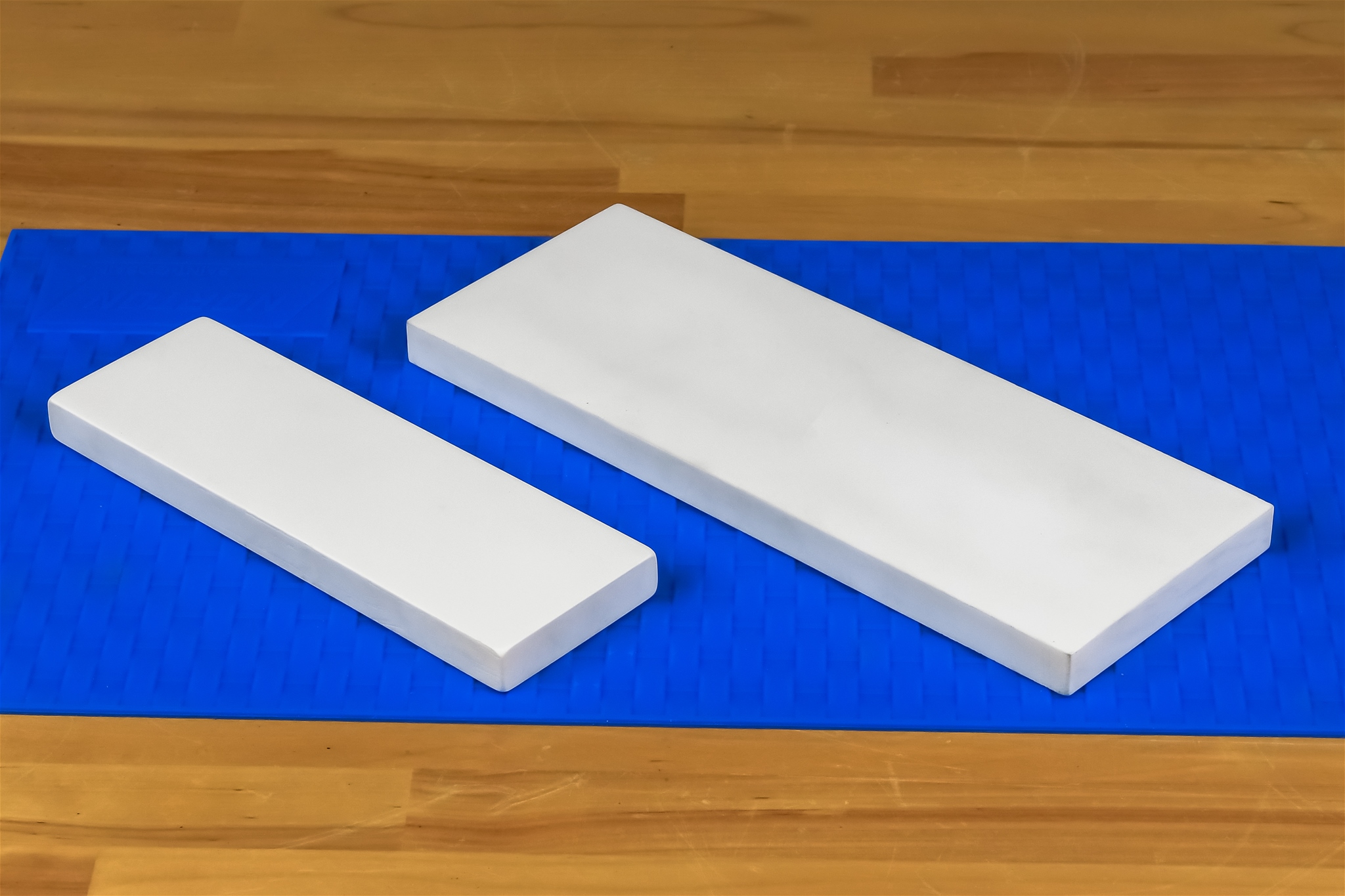

Norton Ascent Ceramic Stone - Fine

Fine grit Norton Ascent Ceramic Stones are now available. The Norton Ascent is a true ceramic stone and is machined flat. It is used dry and doesn’t require flattening, so the stone is always ready for use.

www.sharpeningsupplies.com

Anybody tried one...?