Hallo ,

I am new in the forum and have a little experience with a SR.

I recently bought a vintage SR ,which need a restoration.

The razor is Erik Anton Berg made in Eskilsuna/Sweden. It is a 4/8 French point and i belive it is a 1/4 Hallow grounded.

I have cleaned it twice with a bath of Alcohol 70 % and hydrogen peroxide 3%.

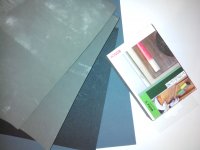

I have sanded the blade with wet sand paper 600-2000 grit and try to polish scale and blade with tooth paste.

I try to hone it on fine grade coticule but it took me 4 hour to set bevel and get it to shave arm hairs.

There is some rust in pin area because i do not have any tools to can get the pin off and remove blade from scale to sand it properly.

I do not have any rotary tool to help me polishing the blade and own only one coticule.

So i am glad to get any advice which can help me restore this razor, because i do not see any point of having a razor, which i con not use as shaver.

Thank you all for your time and answers.

Kind regards

I am new in the forum and have a little experience with a SR.

I recently bought a vintage SR ,which need a restoration.

The razor is Erik Anton Berg made in Eskilsuna/Sweden. It is a 4/8 French point and i belive it is a 1/4 Hallow grounded.

I have cleaned it twice with a bath of Alcohol 70 % and hydrogen peroxide 3%.

I have sanded the blade with wet sand paper 600-2000 grit and try to polish scale and blade with tooth paste.

I try to hone it on fine grade coticule but it took me 4 hour to set bevel and get it to shave arm hairs.

There is some rust in pin area because i do not have any tools to can get the pin off and remove blade from scale to sand it properly.

I do not have any rotary tool to help me polishing the blade and own only one coticule.

So i am glad to get any advice which can help me restore this razor, because i do not see any point of having a razor, which i con not use as shaver.

Thank you all for your time and answers.

Kind regards

Attachments

-

IMG_20190715_164518.jpg1.4 MB · Views: 57

IMG_20190715_164518.jpg1.4 MB · Views: 57 -

IMG_20190715_164552.jpg1.3 MB · Views: 57

IMG_20190715_164552.jpg1.3 MB · Views: 57 -

IMG_20190715_164611.jpg1.3 MB · Views: 53

IMG_20190715_164611.jpg1.3 MB · Views: 53 -

IMG_20190715_164632.jpg1.3 MB · Views: 54

IMG_20190715_164632.jpg1.3 MB · Views: 54 -

IMG_20190715_164713.jpg1.2 MB · Views: 56

IMG_20190715_164713.jpg1.2 MB · Views: 56 -

IMG_20190715_165216.jpg1.6 MB · Views: 51

IMG_20190715_165216.jpg1.6 MB · Views: 51 -

IMG_20190715_165119.jpg1.2 MB · Views: 52

IMG_20190715_165119.jpg1.2 MB · Views: 52 -

IMG_20190715_164959.jpg1.3 MB · Views: 53

IMG_20190715_164959.jpg1.3 MB · Views: 53