You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first Gold Dollar 66 honing - critic please !

- Thread starter luv2shave

- Start date

Slash McCoy

I freehand dog rockets

Agreed. Unless you would like it to be even better than it is. Remember, you aren't risking much. These are the cheapest shave capable razors you can get. Better to go nuts on a chimp change GD than a potentially very nice Dubl Duck or Genco or Wosty.If you like how it is shaving now......keep it as is.....

- Thread starter

- #23

I had ordered Four GD66, Two GD208 razors from Aliexpress along with Two of Titan ACRM-2.

From my recent experience dealing with the 2 GD66 and what i read on this thread I think I may have to order a 10 pack to get my honing act together. The cheapest gold dollar 10 razor lot I see on Aliexpress is $43 with free shipping to NY, which drops down to around $40 for multiple lots of 10. I do not think I will ever buy a 100 GD66's for $2 from the factory. Is this the best price for around 20 razors and free shipping ?

From my recent experience dealing with the 2 GD66 and what i read on this thread I think I may have to order a 10 pack to get my honing act together. The cheapest gold dollar 10 razor lot I see on Aliexpress is $43 with free shipping to NY, which drops down to around $40 for multiple lots of 10. I do not think I will ever buy a 100 GD66's for $2 from the factory. Is this the best price for around 20 razors and free shipping ?

rbscebu

Girls call me Makaluod

Have you looked at Alibaba (not AliExpress)?

I don't think that you'll get much better than that..... The cheapest gold dollar 10 razor lot I see on Aliexpress is $43 with free shipping to NY, which drops down to around $40 for multiple lots of 10. I do not think I will ever buy a 100 GD66's for $2 from the factory. Is this the best price for around 20 razors and free shipping

First of all, great job. Biggest issue with a GD is to get the geometry right, and the best way to do that is to keep going, until you have good bevel set. It's not precious metal. Doesn't matter if the spine wear looks wonky, as long as it sits flat on the hone, with no wobble.

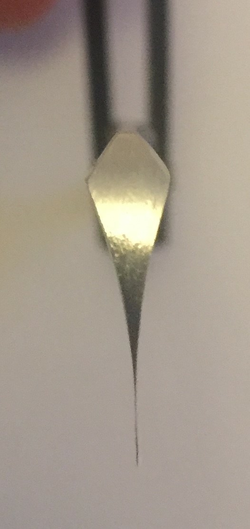

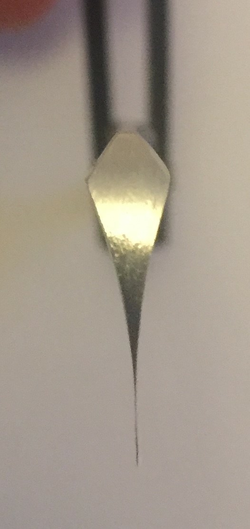

Here is a GD66 that I tried a few things on:

Changed the side profile to get rid of the shoulder altogether, and create a thumb notch. There are more subtle ways of doing it, if you don't want to change the profile, but I prefer to get rid of it altogether.

Thinned the spine, going for a diamond shaped profile instead of trying to thin it flat and moving the grid up to meet it.

I also tried a bit of hollow grinding, but that is difficult to get right. Must be why it was considered a specialised craft in it's day

It may be an ugly duckling, but it shaves great!

Here is a GD66 that I tried a few things on:

Changed the side profile to get rid of the shoulder altogether, and create a thumb notch. There are more subtle ways of doing it, if you don't want to change the profile, but I prefer to get rid of it altogether.

Thinned the spine, going for a diamond shaped profile instead of trying to thin it flat and moving the grid up to meet it.

I also tried a bit of hollow grinding, but that is difficult to get right. Must be why it was considered a specialised craft in it's day

It may be an ugly duckling, but it shaves great!

Last edited:

- Thread starter

- #26

Have you looked at Alibaba (not AliExpress)?

I don't think that you'll get much better than that.

They are cheaper on Alibaba, from the original maker of the razors I think - at around $2.50 when you buy a minimum of 100 plus shipping - comes to around the same for lesser numbers n Aliexpress with free shipping. Who needs a 100 - right ?

- Thread starter

- #27

First of all, great job. Biggest issue with a GD is to get the geometry right, and the best way to do that is to keep going, until you have good bevel set. It's not precious metal. Doesn't matter if the spine wear looks wonky, as long as it sits flat on the hone, with no wobble.

Here is a GD66 that I tried a few things on:

Changed the side profile to get rid of the shoulder altogether, and create a thumb notch. There are more subtle ways of doing it, if you don't want to change the profile, but I prefer to get rid of it altogether.

View attachment 1473038

Thinned the spine, going for a diamond shaped profile instead of trying to thin it flat and moving the grid up to meet it.

View attachment 1473041

I also tried a bit of hollow grinding, but that is difficult to get right. Must be why it was considered a specialised craft in it's day

It may be an ugly duckling, but it shaves great!

Wow ! that looks amazing. Did you use a dremel to cut the shoulder ?

No I used a bench sander similar to the pic. I removed the top guard and cut some of the support metal away to allow me to use the small top pulley as a contact wheel.Wow ! that looks amazing. Did you use a dremel to cut the shoulder ?

Dremel have their uses, but like @Slash McCoy pointed out, it is risky. First thing you learn when using them is that the rotation direction should always be from the spine towards the edge. If you go the wrong direction, it will grab the edge and either rip out a chunk of your edge, or yank it out of your hand and send it flying. They also rotate at very high speeds and its easy to overheat the thin steel around the edge, if you are not very careful.

A belt sander is much more suitable, and not much more expensive. They are also great for making scales.

Slash McCoy

I freehand dog rockets

Yes, that is a pretty good price for a 10-pack these days. Bulk orders through AliBaba (100 lots) from the factory do not ship free. I never got hit for duty, or sales tax, though. For small lots the price you see on AE is pretty close to rock bottom. At that price you could hone and sell them profitably.I had ordered Four GD66, Two GD208 razors from Aliexpress along with Two of Titan ACRM-2.

From my recent experience dealing with the 2 GD66 and what i read on this thread I think I may have to order a 10 pack to get my honing act together. The cheapest gold dollar 10 razor lot I see on Aliexpress is $43 with free shipping to NY, which drops down to around $40 for multiple lots of 10. I do not think I will ever buy a 100 GD66's for $2 from the factory. Is this the best price for around 20 razors and free shipping ?

The cheapest I ever got a box of 10 for, from a reseller, was $3.17/ea, shipped, but that was several years ago.

As for getting your honing act together, once you fix the heel, (probably half of ALL razors would benefit from that, actually.) and set the bevel, the rest is pretty easy. The fastest way to get your first laser beam edge is with Newbie Honing Compendium | Badger & Blade . There are many ways to get a razor sharp, but this way can get your razor sharper than a pro will hone it, by your second attempt, if you can follow directions precisely. A lot of guys simply can't. Mental block or something. Or else no faith in The Method.

- Thread starter

- #31

Yes, that is a pretty good price for a 10-pack these days. Bulk orders through AliBaba (100 lots) from the factory do not ship free. I never got hit for duty, or sales tax, though. For small lots the price you see on AE is pretty close to rock bottom. At that price you could hone and sell them profitably.

The cheapest I ever got a box of 10 for, from a reseller, was $3.17/ea, shipped, but that was several years ago.

As for getting your honing act together, once you fix the heel, (probably half of ALL razors would benefit from that, actually.) and set the bevel, the rest is pretty easy. The fastest way to get your first laser beam edge is with Newbie Honing Compendium | Badger & Blade . There are many ways to get a razor sharp, but this way can get your razor sharper than a pro will hone it, by your second attempt, if you can follow directions precisely. A lot of guys simply can't. Mental block or something. Or else no faith in The Method.

Truth be told I have read each and every post in this thread, and the thread where you speak about "the method". My balsa boards and acrylic and the diamond pastes are on the way. I have seen your video about using the balsa strop in great detail. (i am the guy commenting recently a lot on your videos and asking questions too

The heel correction is new to me, the burr method has been very helpful to allow me whatever little fine edge I could get and shave comfortably. Laser edge is the next step with these new learnings under my belt. Howver I realise the key to all of this is more practice with what I have than buying more stuff. I spend some time daily to put these learnings to use and attempt a shave with my edge. some days its fantastic, other days its not. But I am slowly getting there.

Another question. What sort of non-power tools would I need to do modifications to a straight razor? Just a few metal files and sandpaper?A dremel is wonderful. A dremel is also horrible. You will ruin a few razors, almost certainly, with it. When you are ruining a GD66 and you have 99 more because you bought 100 from the factory for $2 each, it's all fun and games. When you are putting the final touches on your only GD, getting it ready for the annual competition with deadline only three days out, it is heartbreaking. When you are just gently touching up a slightly abused vintage Filly, it is excruciating anguish, rending of garments and gnashing of teeth. When you have a half dozen GD208 razors and you hope to get one super killer blade out of the lot, worthy of new scales and a good polish, that is being realistic. When you have already done 20 or 30 and you think you got the hang of it, famous last words. When you have a few under your belt and you are totally focused and concentrating because you know how you can send shattered splinters of steel all over the room and into any unshielded eyeball, but you are not one to waste time when the careful use of powertools has been proven to be a force multiplier and time saver for you, then maybe that is pretty smart and logical.

I honestly think no power tools is a good policy for your first few modifications. However, I have no dog in that fight. Not my eyeballs or razors at risk, after all. Anyway, I will never know unless you post about your catastrophe.

Just sayin, the big orange heavy duty knockoff sold by Harbor Freight under the Chicago brand is half the cost and lasts twice as long, and has the same size chuck so you can use the same bits and bobs. Don't waste your money on the little stones or steel burrs or diamond bits. There are two things you will use a lot of, and that is the sanding drum attachment and the little sanding drums for it, the felt polishing wheels, and less used, the cutting disks. Those disks shatter a LOT. The other two tools can grab an edge and fling a razor over the goalpost, or shatter it into shrapnel, or overheat the thin steel near the edge for a BSOD. Bad stuff happens fast, at 30,000 RPM.

If you go for it, get two things for sure. Goggles, AND a full face mask. You WILL be glad you did, maybe later but probably sooner.

Doing a heel without power tools works every bit as well as using them successfully. Just takes a little longer. Did the doctor only give you 6 more hours to live or something? Take your time. Think about what you are doing. Stop and carefully regard your progress and how much is still to do. Save your money. That's my considered suggestion.

I honed one of these years ago, still have nightmares about it, but I can shave with it and actually have a decent shave. If you are happy with the shave, you have succeeded, well done I say.

Depends on what sort of modifications.Another question. What sort of non-power tools would I need to do modifications to a straight razor? Just a few metal files and sandpaper?

Also, yes.

Slash McCoy

I freehand dog rockets

A file doesn't work on a razor once it is hardened. The razor is about the same hardness or harder than the file teeth. Sandpaper and various homemade sanding blocks and forms and jigs, and of course a few coarse stones and cheap charlie Harbor Freight diamond plates. You can carve specially shaped sanding blocks out of wood, or mold them out of polyester or epoxy resin, or aluminum, or whatever. Garden hose and other types of rubber hose can be useful. Rags and 1µ or coarser diamond paste are useful for removing deep scratches from coarse sandpaper. Mostly, the main modification that you might want to do without power tools would be a heel correction, and all you need is a Norton 220 or similar. Oh, and spine thinning. You can do that on coarse stones, sandpaper, or diamond plates. Stuff like shank thinning, nose reprofiling, etc, you probably want a dremel or a knockoff, and maybe a belt sander, too.Another question. What sort of non-power tools would I need to do modifications to a straight razor? Just a few metal files and sandpaper?

Diamond files work fine on a razor. Good ones cost $$, but you can make headway even with the crappy cheap ones, if you have patience.

What about Arkansas novaculite files like the ones you can get from Dan's?Diamond files work fine on a razor. Good ones cost $$, but you can make headway even with the crappy cheap ones, if you have patience.

- Thread starter

- #39

I have used a dmt coarse plate to mercilessly grind off the shoulder within minutes. With some gentle rounding strokes also helped to round off the toe tip

rbscebu

Girls call me Makaluod

Takes some of the fun out of SR shaving.I have used a dmt coarse plate to mercilessly grind off the shoulder within minutes. With some gentle rounding strokes also helped to round off the toe tip

Similar threads

- Replies

- 19

- Views

- 1K