Hi all,

The genesis of this thread can be found here.

I am documenting my attempt at honing a T.I. Super Gnome to Feather like sharpness. My current honing equipment consists of a complete set of Spyderco hones, a Hand American base, one leather plate for it loaded with CrO, one glass plate for it with nothing on it yet(I was planning on trying some of the 3M micro abrasive papers on it) and a nice hanging strop from Tony.

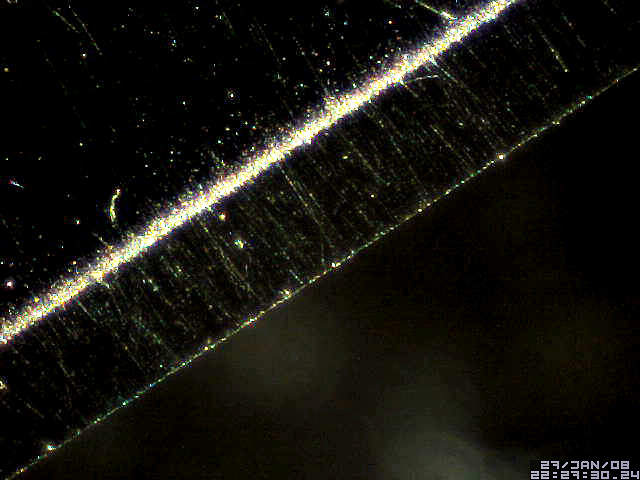

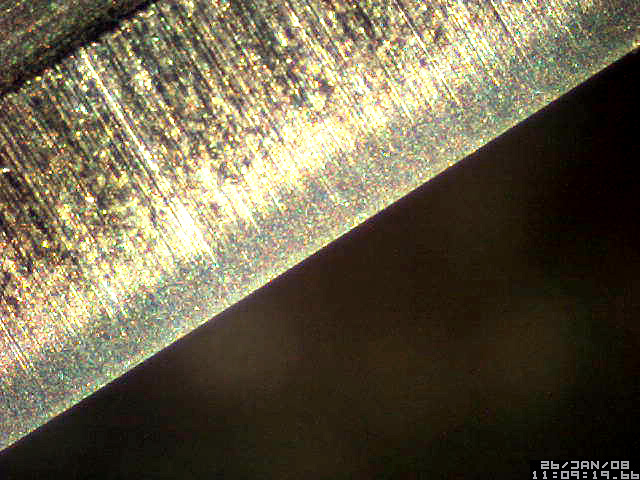

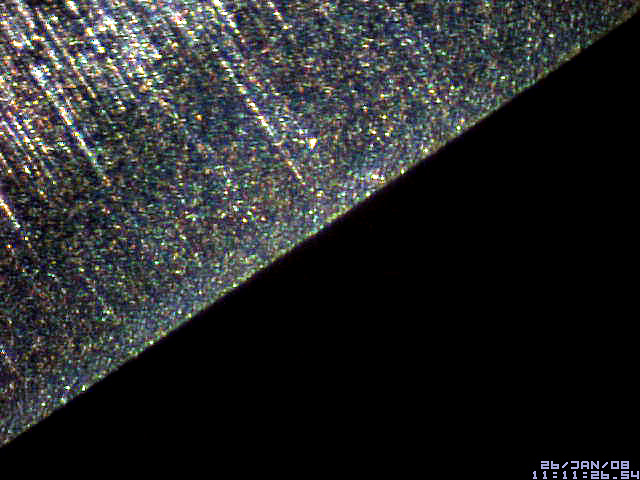

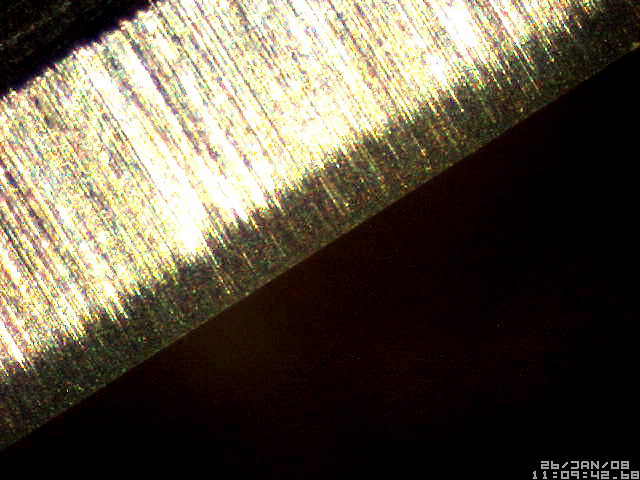

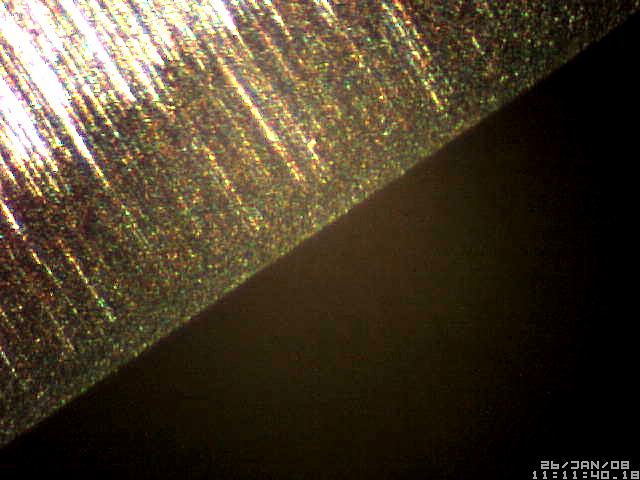

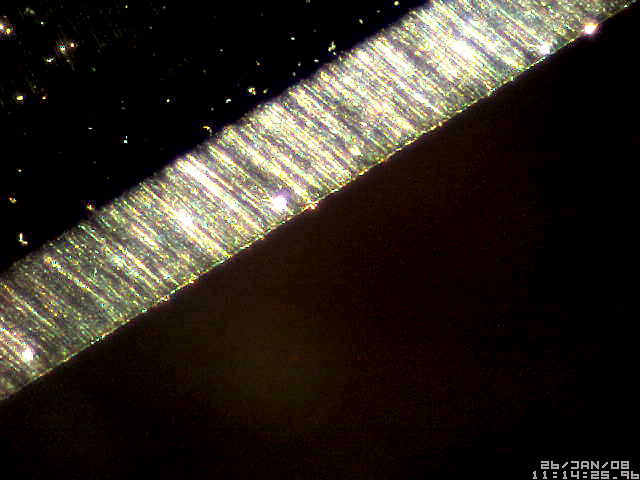

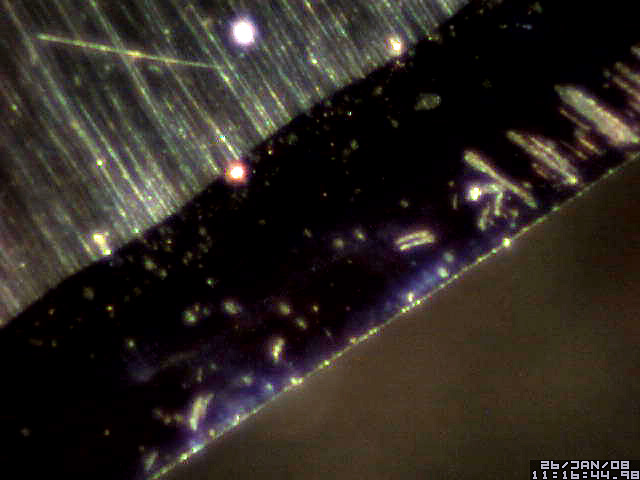

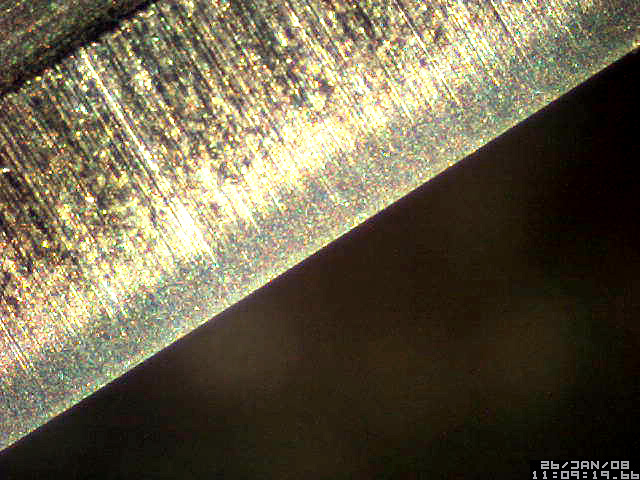

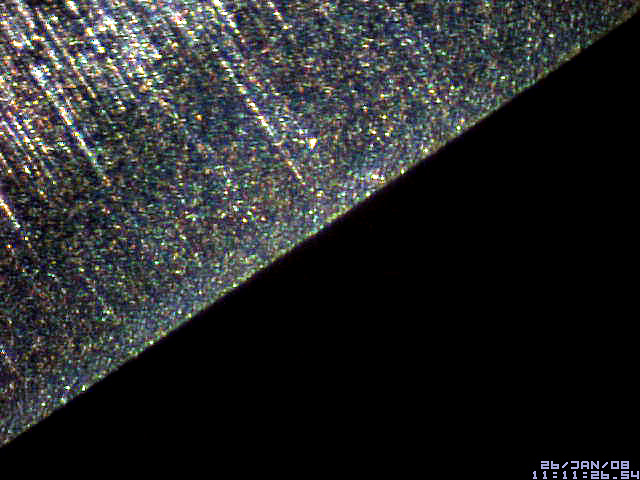

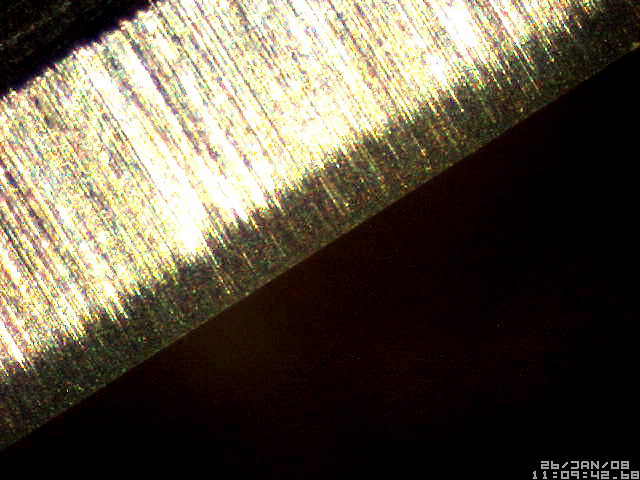

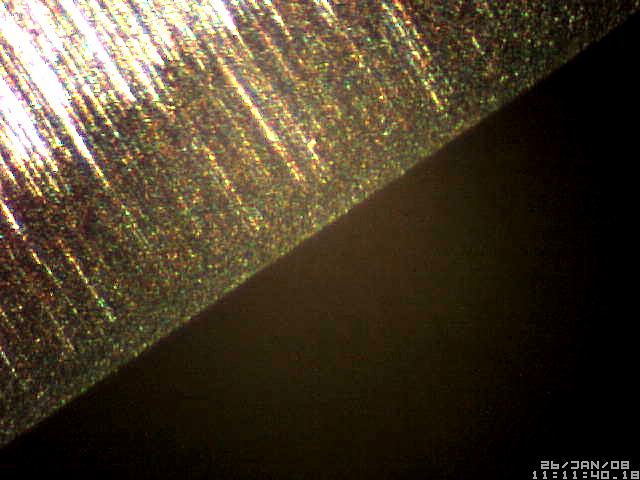

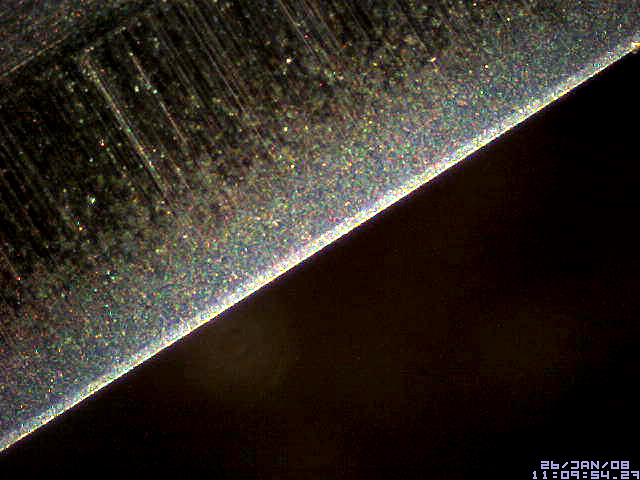

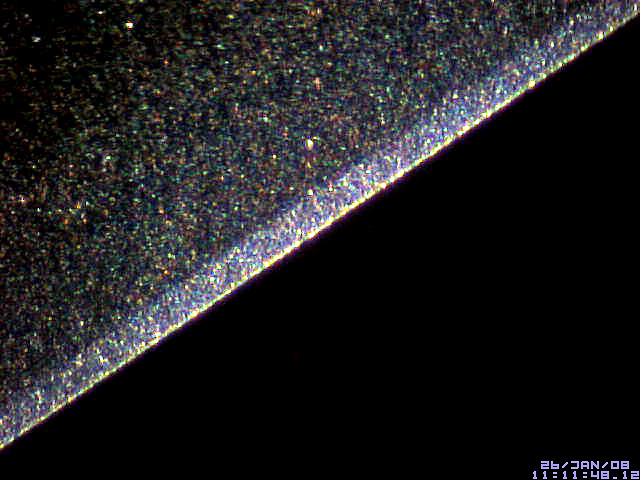

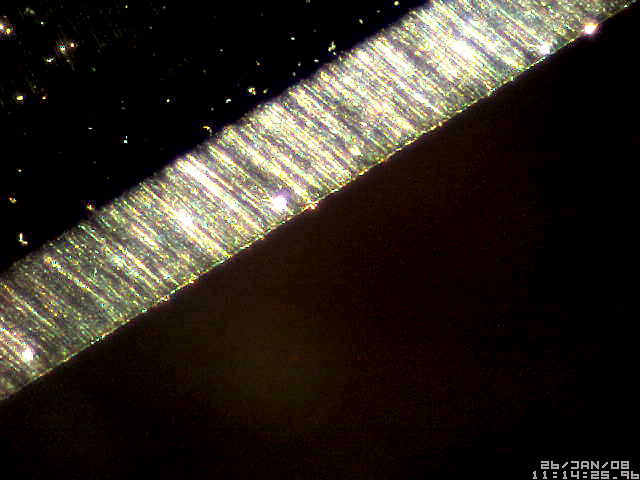

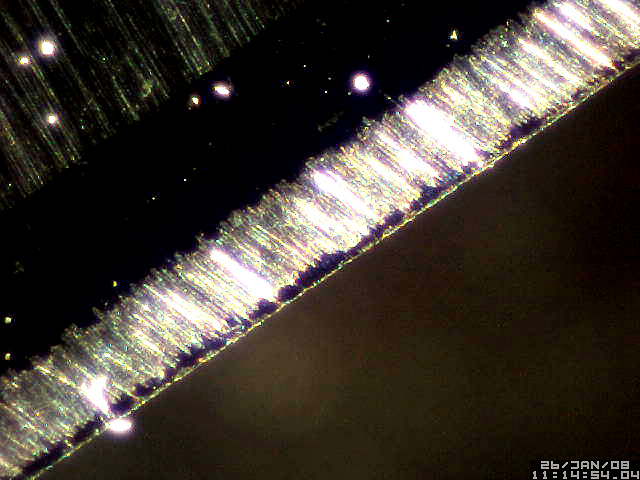

The first step is to identify a goal and see what the edge of a fresh Feather Professional Super blade looks like. Here is just such a blade under various magnifications and lighting conditions:

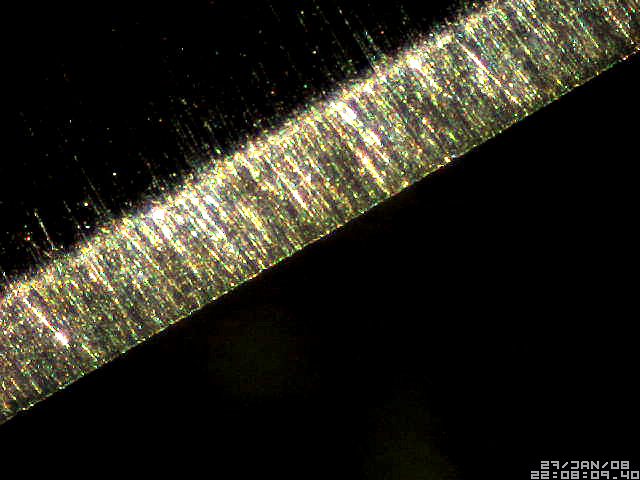

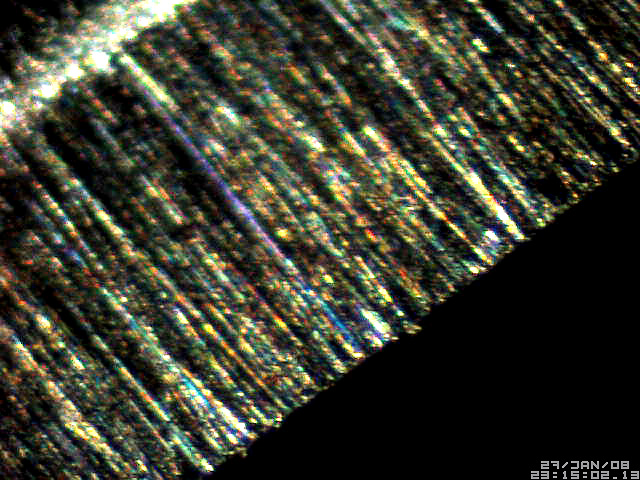

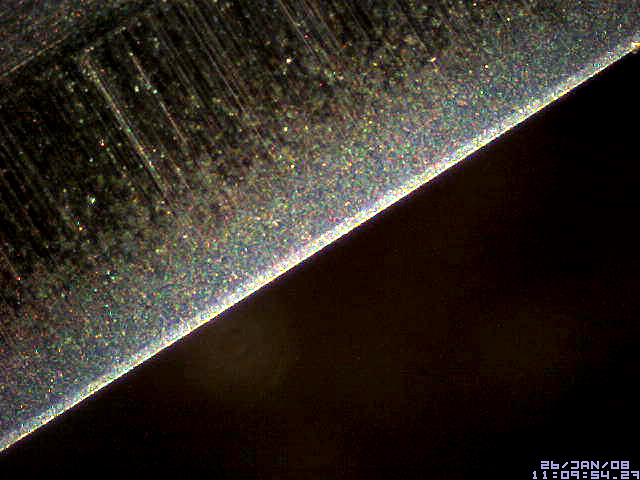

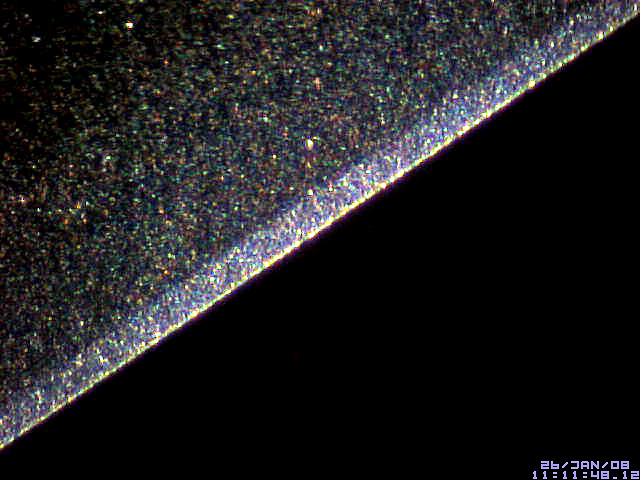

Feather Pro Super at 60x, Front Lighting

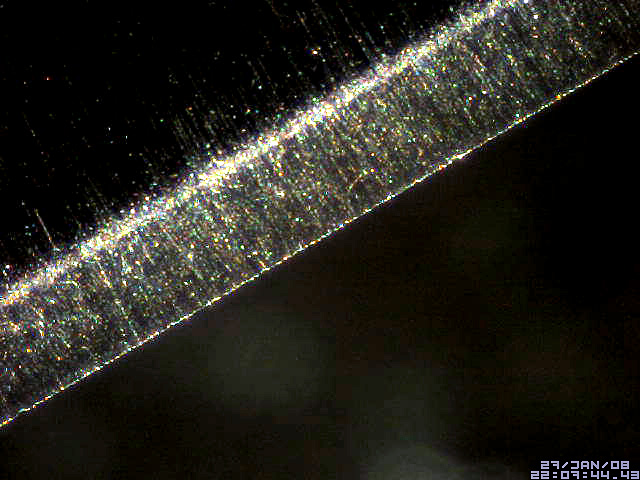

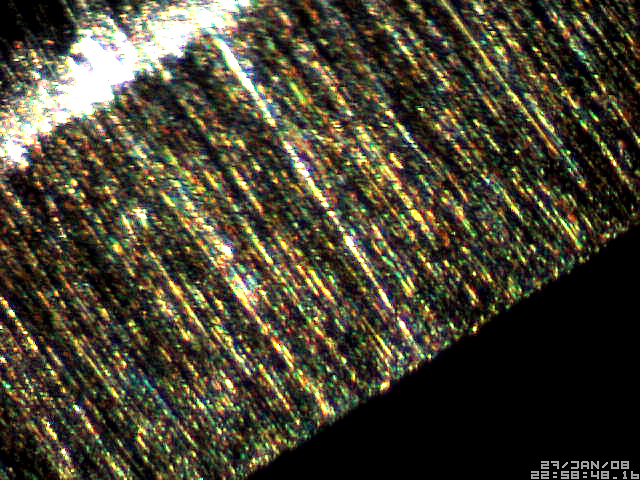

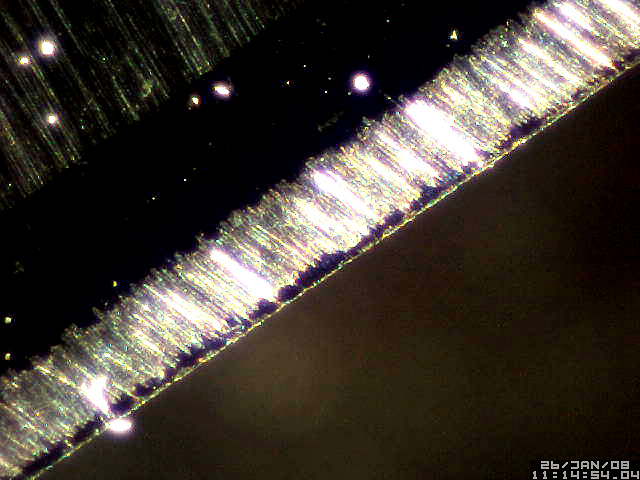

Feather Pro Super at 200x, Front Lighting

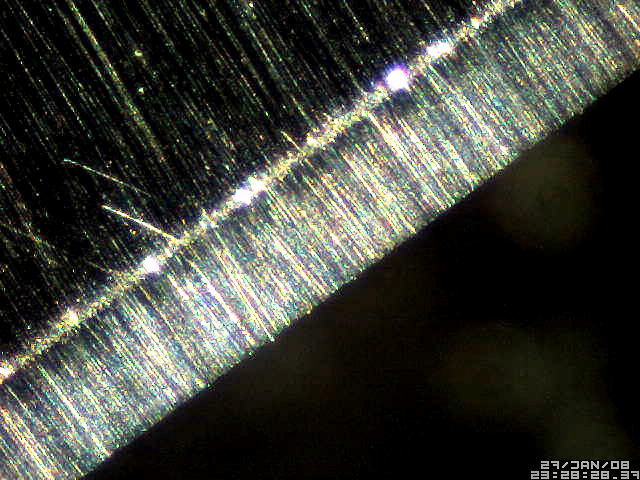

Feather Pro Super at 60x, Side Lighting

Feather Pro Super at 200x, Side Lighting

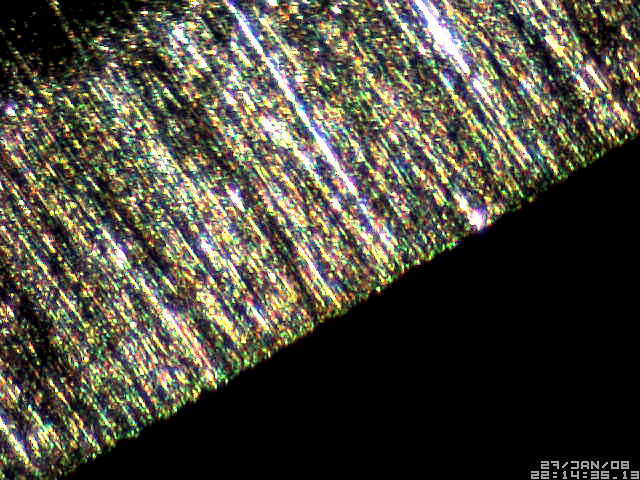

Feather Pro Super at 60x, Edge Lighting

Feather Pro Super at 200x, Edge Lighting

We can observe a few things. We can see that the honing scratches have been completely polished away leaving a very smooth edge. They are using a very fine grit in the final honing & polishing stages. This appears to be a VERY sharp edge! We can also see that Feather uses three bevels on their edges. This in undoubtedly for efficiency. The tiny size of the third bevel, clearly seen in the edge lighting micrographs, also explains why these edge don't last long. We can also see how uniform and completely smooth the third bevel is.

Now we know what we are aiming for.

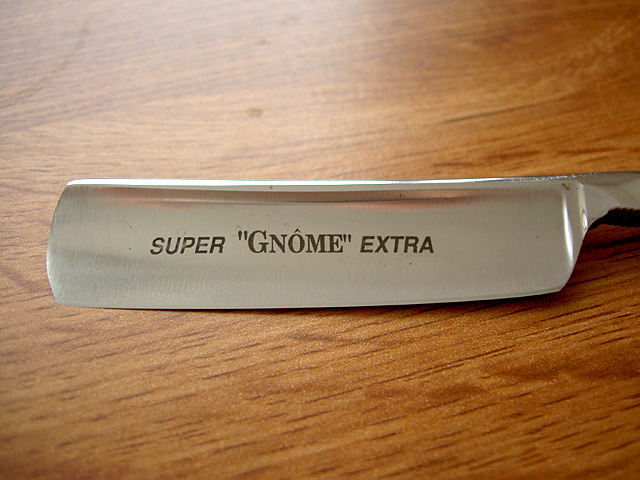

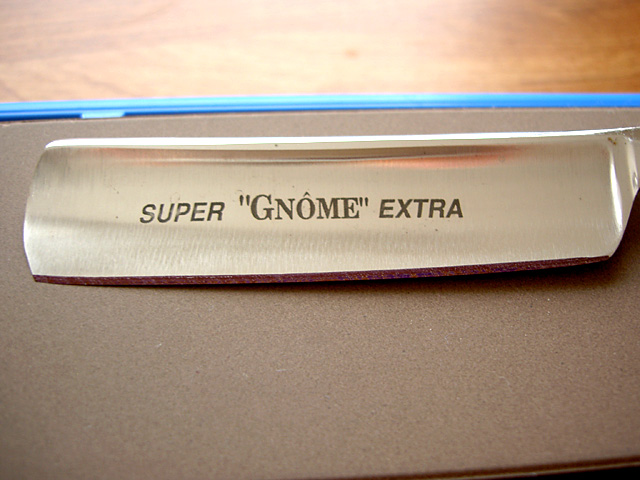

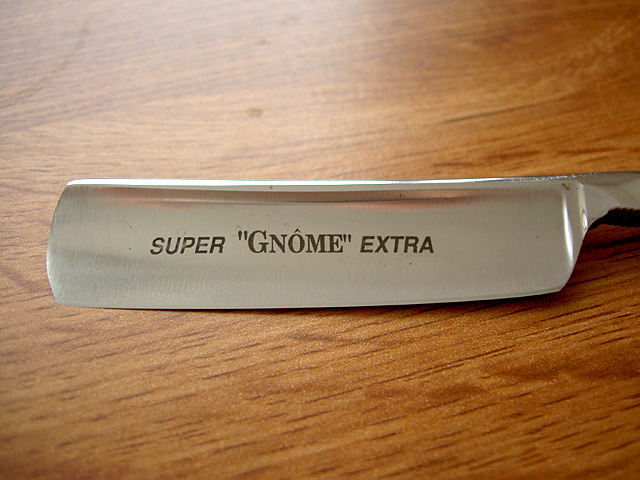

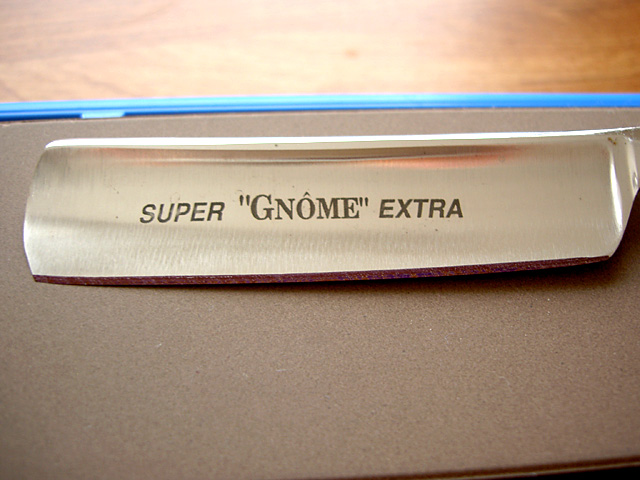

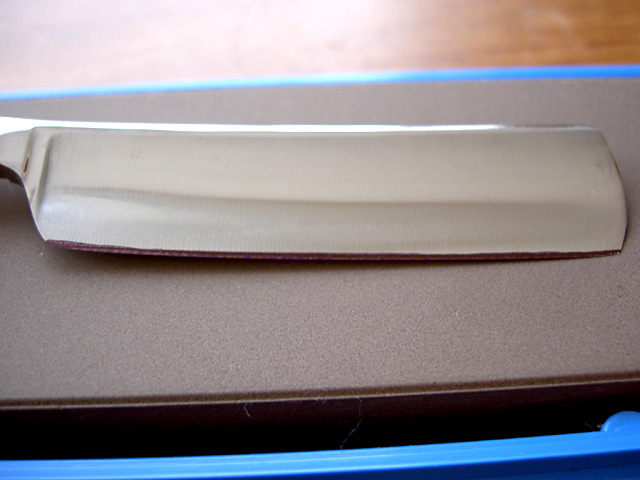

The next step is to begin to hone my T.I. Super Gnome, hereafter referred to as the SG. I just purchased this razor from classic.

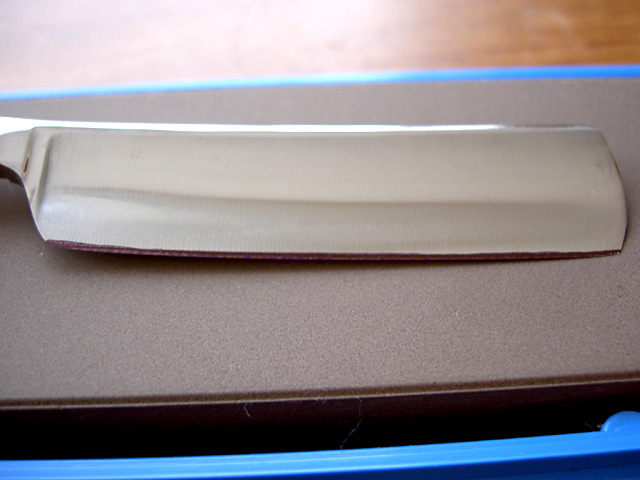

Here is the blade before we begin:

I decided to use the old trick of marking the blade edge with a permanent marker in order to see where the hone is removing metal from and gauge progress towards a uniform bevel.

Here is the blade as marked on both sides:

I then proceed to give the blade 10 round trip strokes on the Spyderco Medium grit hone. I was very careful to keep the blade flat on the stone, not raising the edge or spine and used very light pressure.

Here is the result:

Right away I have encountered a problem. The hone is clearly not removing metal evenly across the length of the blade. The bevel is not uniform. While it appears the most of the bevel is in contact with the hone, the heel and toe are not. In fact about 1/3 of the blade from the toe down is not being honed and the last 1/2 centimeter near the heel has the same issue.

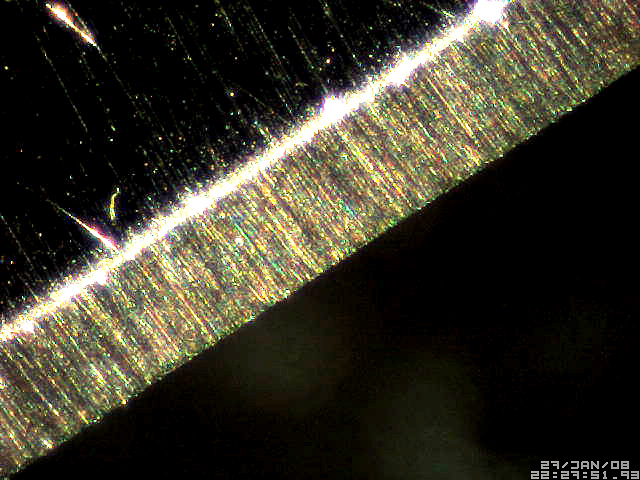

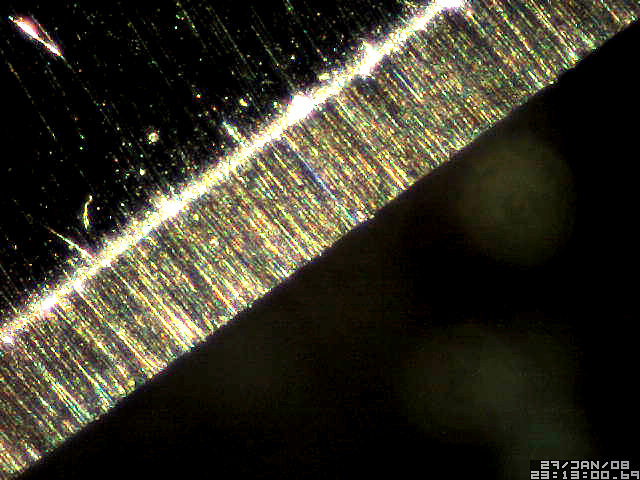

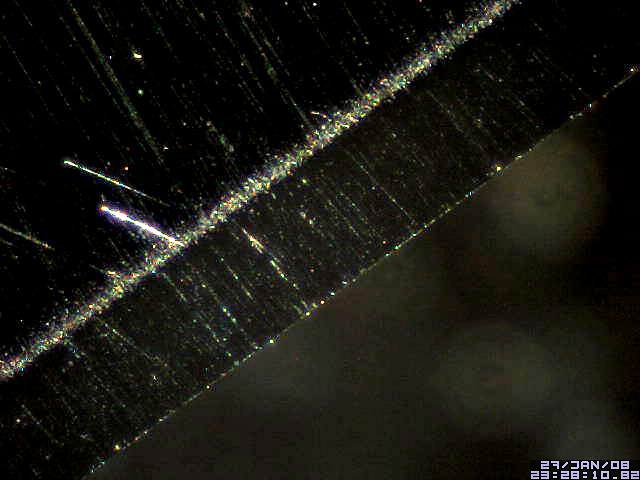

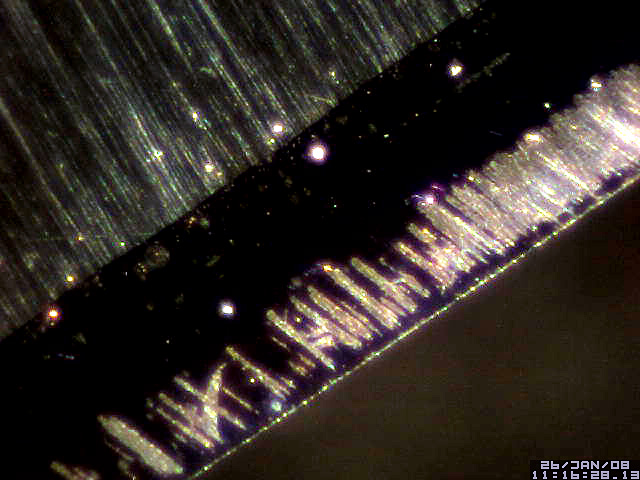

Here are some micrographs of the edge at 60x:

Mid blade

The bevel is uniform here and the marker has been removed all the way down to the edge. This is what we want to see all along the length of the blade.

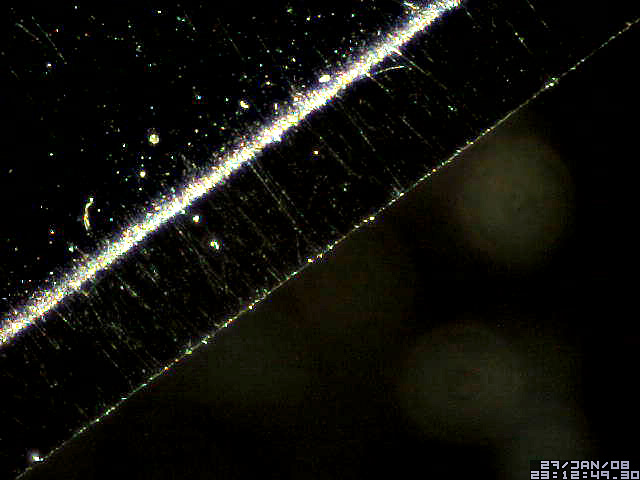

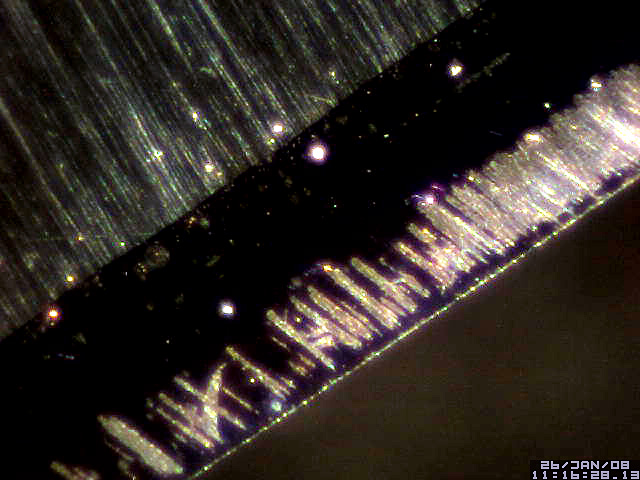

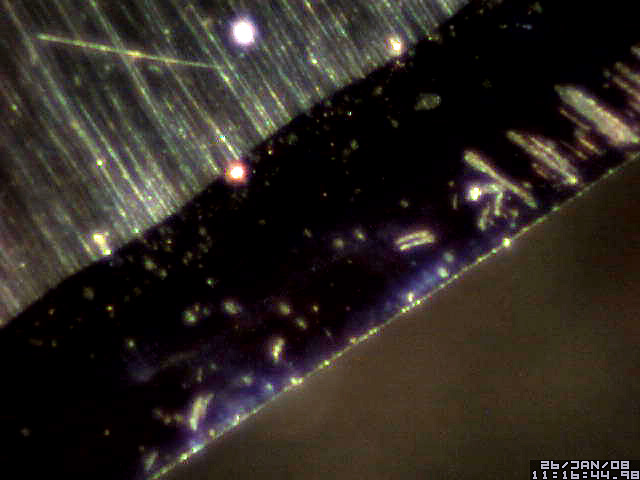

Here is the edge 2/3 of the way up towards the toe:

The bevel is not uniform here or in complete contact with the hone. There is a strip near the edge where the bevel does not extend all the way down. We are not sharpening the edge at this point, just setting a new bevel. Of course the problem gets worse the closer to the toe we get as seen in the next two micrographs:

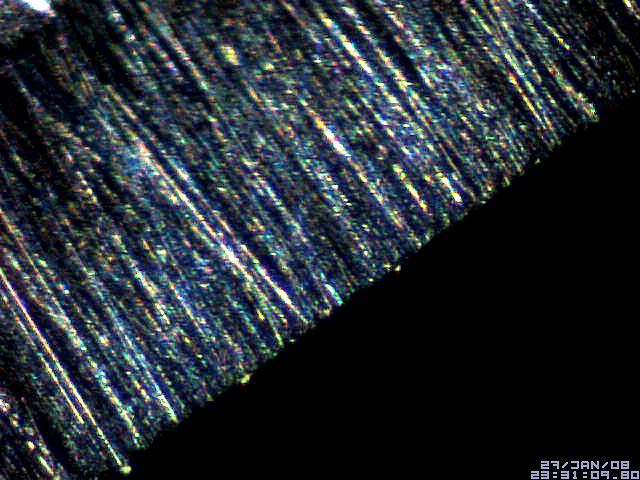

Nearer to the toe

Proceeding any farther at this point would be useless as the bevel is not uniform. So now my question is what to do? I've been sharpening knives and woodworking tools for years and normally at this point would drop down to a lower grit and keep on honing until the bevel is uniform and metal/marker is being removed along the entire length in every stroke. I'm not sure that is the right course in this case as I'm still new at razor honing. What say the honemeisters? What should I do?

Thanks,

Joe

The genesis of this thread can be found here.

I am documenting my attempt at honing a T.I. Super Gnome to Feather like sharpness. My current honing equipment consists of a complete set of Spyderco hones, a Hand American base, one leather plate for it loaded with CrO, one glass plate for it with nothing on it yet(I was planning on trying some of the 3M micro abrasive papers on it) and a nice hanging strop from Tony.

The first step is to identify a goal and see what the edge of a fresh Feather Professional Super blade looks like. Here is just such a blade under various magnifications and lighting conditions:

Feather Pro Super at 60x, Front Lighting

Feather Pro Super at 200x, Front Lighting

Feather Pro Super at 60x, Side Lighting

Feather Pro Super at 200x, Side Lighting

Feather Pro Super at 60x, Edge Lighting

Feather Pro Super at 200x, Edge Lighting

We can observe a few things. We can see that the honing scratches have been completely polished away leaving a very smooth edge. They are using a very fine grit in the final honing & polishing stages. This appears to be a VERY sharp edge! We can also see that Feather uses three bevels on their edges. This in undoubtedly for efficiency. The tiny size of the third bevel, clearly seen in the edge lighting micrographs, also explains why these edge don't last long. We can also see how uniform and completely smooth the third bevel is.

Now we know what we are aiming for.

The next step is to begin to hone my T.I. Super Gnome, hereafter referred to as the SG. I just purchased this razor from classic.

Here is the blade before we begin:

I decided to use the old trick of marking the blade edge with a permanent marker in order to see where the hone is removing metal from and gauge progress towards a uniform bevel.

Here is the blade as marked on both sides:

I then proceed to give the blade 10 round trip strokes on the Spyderco Medium grit hone. I was very careful to keep the blade flat on the stone, not raising the edge or spine and used very light pressure.

Here is the result:

Right away I have encountered a problem. The hone is clearly not removing metal evenly across the length of the blade. The bevel is not uniform. While it appears the most of the bevel is in contact with the hone, the heel and toe are not. In fact about 1/3 of the blade from the toe down is not being honed and the last 1/2 centimeter near the heel has the same issue.

Here are some micrographs of the edge at 60x:

Mid blade

The bevel is uniform here and the marker has been removed all the way down to the edge. This is what we want to see all along the length of the blade.

Here is the edge 2/3 of the way up towards the toe:

The bevel is not uniform here or in complete contact with the hone. There is a strip near the edge where the bevel does not extend all the way down. We are not sharpening the edge at this point, just setting a new bevel. Of course the problem gets worse the closer to the toe we get as seen in the next two micrographs:

Nearer to the toe

Proceeding any farther at this point would be useless as the bevel is not uniform. So now my question is what to do? I've been sharpening knives and woodworking tools for years and normally at this point would drop down to a lower grit and keep on honing until the bevel is uniform and metal/marker is being removed along the entire length in every stroke. I'm not sure that is the right course in this case as I'm still new at razor honing. What say the honemeisters? What should I do?

Thanks,

Joe

Nice pictures though too. I think these threads really help people learn to hone.

Nice pictures though too. I think these threads really help people learn to hone. This might prove to be the one hurdle I can't clear.

This might prove to be the one hurdle I can't clear.