- Thread starter

- #81

I was thinking about the practicality of taping razors that clamp down on a blade very close to the edges. In pondering the possibilities, this is what I came up with for my NEW SC.

.View attachment 840862

That's 2 layers of Frogtape at the center of the baseplate and 2 at the edges of the topcap. I plan to try it out tomorrow with a fresh Feather New Hi-Stainless.

That vintage Silver Star is destined to become a shim. It's stainless steel and much thicker and stiffer than modern blades. (I did shave with that Silver Star twice, and that was quite enough for me)

Why elevate the cap in the middle with tape? Is the center tape for making a tighter fit for blade alignment?

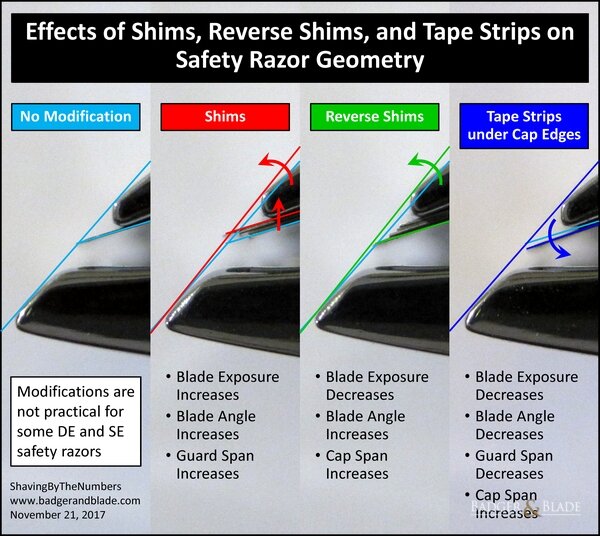

It just hit me that another reason for the drop in blade exposure is that the tape near the edge will act like a reverse shim, which shifts the shave plane and decreases the blade exposure even with the same blade curvature. If you have the cap not tightened down as much, that would also shift the shave plane even more vertically and decrease the blade exposure even more.

It just hit me that another reason for the drop in blade exposure is that the tape near the edge will act like a reverse shim, which shifts the shave plane and decreases the blade exposure even with the same blade curvature. If you have the cap not tightened down as much, that would also shift the shave plane even more vertically and decrease the blade exposure even more.