Flintstone65

Imagining solutions for imaginary problems

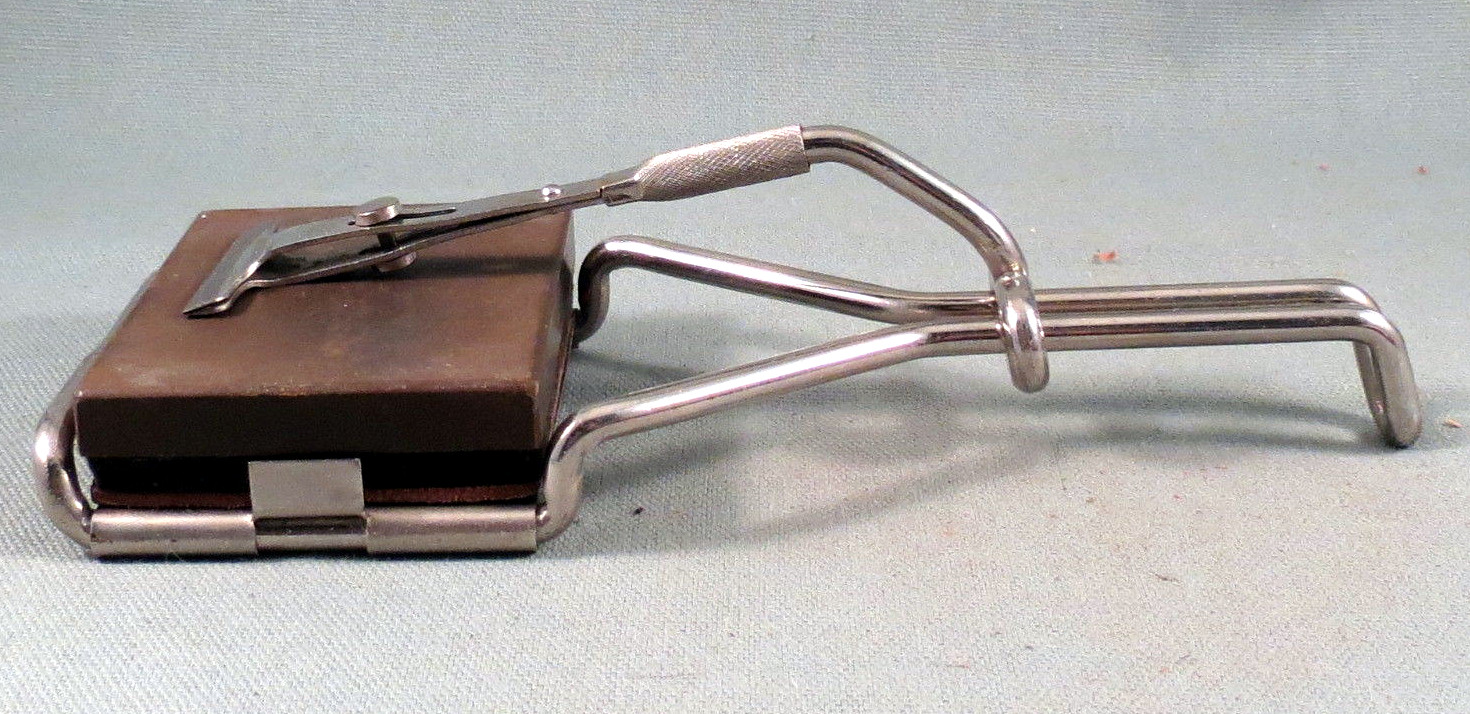

This is my Eagle Lather Catcher, and it is a stellar shaver, but it does require a proprietary blade. Luckily, it isn’t all that difficult to modify a GEM blades to fit these razors.

I modified two blades, the first one I didn’t take the following safety precautions (and paid the price); the second one went much smoother with these changes in place:

I started with a GEM SS PTFE, and my Eagle Improved came with a set of blades -- here's the before shot.

Here's the spine off and cutting edge taped, and 2 of the 3 tools I used -- didn't take a pic of the aviation snips.I have a beater-knife that I use to pry the spine edge a bit, and then use the pliers to pull the spine off. You need the spine, so care needs to be taken that you don't mangle it in the process -- it's soft metal.

Here's where things went a little sideways. The first mark I made (leftmost pic) and my first cut (middle pic) is where I thought I should be cutting....but it consistently made my blade too tall. So I made a 2nd mark (3rd pic) and cut to that line, and that seemed to be the sweet spot for me. Again, I can't explain why that was the case....maybe I miscalculated where I should cut initially, or I cut too far above the line, or I didn't get the spine set down deep enough (probably all of the above), but the 2nd line (making the blade shorter) worked for me.

I got lazy with the camera and didn't show the results after the 2nd cut -- which would've been helpful. But here is the final end product for me. I've shaved a couple of times and found it fits and shaves well.

It's an awesome razor, and well worth the "trouble" of modding the blades. And it really isn't a bad/difficult process at all. I'm glad I did at least 2 blades (and will probably do a few more soon) just so that I have them on hand. And if you have one of these razors, or another type of lather catcher, or maybe you just really like the look of these razors....if any of those are true, then you need to check out The Association of Lather Catchers: TALC

I modified two blades, the first one I didn’t take the following safety precautions (and paid the price); the second one went much smoother with these changes in place:

- I definitely recommend putting some painters tape on the edge of the blade to protect yourself throughout the process. It just needs to be a thin strip, you don't want it to interfere with the process. I initially thought I'd just be careful and ended up shaving some of my fingerprints off. No blood, I just found that as I was pulling and pushing, I was apparently holding the blade in such a way that I was finding skin on the sharp end of the blade. That was the first one I did, so the next one I taped the blade and then was ultimately unscathed.

- Once the spine piece is off and marked where you're going to cut, I would do two other things: wear safety goggles, and put a piece of painters tape on the back of the blade where you'll be cutting. The blade being extremely hard and brittle, when I used aviation snips without the tape, my snips threw pieces of steel as I was cutting into the blade. It was like giving Superman a pedicure. So the tape on the back kept any pieces from flying away.

I started with a GEM SS PTFE, and my Eagle Improved came with a set of blades -- here's the before shot.

Here's the spine off and cutting edge taped, and 2 of the 3 tools I used -- didn't take a pic of the aviation snips.I have a beater-knife that I use to pry the spine edge a bit, and then use the pliers to pull the spine off. You need the spine, so care needs to be taken that you don't mangle it in the process -- it's soft metal.

Here's where things went a little sideways. The first mark I made (leftmost pic) and my first cut (middle pic) is where I thought I should be cutting....but it consistently made my blade too tall. So I made a 2nd mark (3rd pic) and cut to that line, and that seemed to be the sweet spot for me. Again, I can't explain why that was the case....maybe I miscalculated where I should cut initially, or I cut too far above the line, or I didn't get the spine set down deep enough (probably all of the above), but the 2nd line (making the blade shorter) worked for me.

I got lazy with the camera and didn't show the results after the 2nd cut -- which would've been helpful. But here is the final end product for me. I've shaved a couple of times and found it fits and shaves well.

It's an awesome razor, and well worth the "trouble" of modding the blades. And it really isn't a bad/difficult process at all. I'm glad I did at least 2 blades (and will probably do a few more soon) just so that I have them on hand. And if you have one of these razors, or another type of lather catcher, or maybe you just really like the look of these razors....if any of those are true, then you need to check out The Association of Lather Catchers: TALC