Chan Eil Whiskers

Fumbling about.

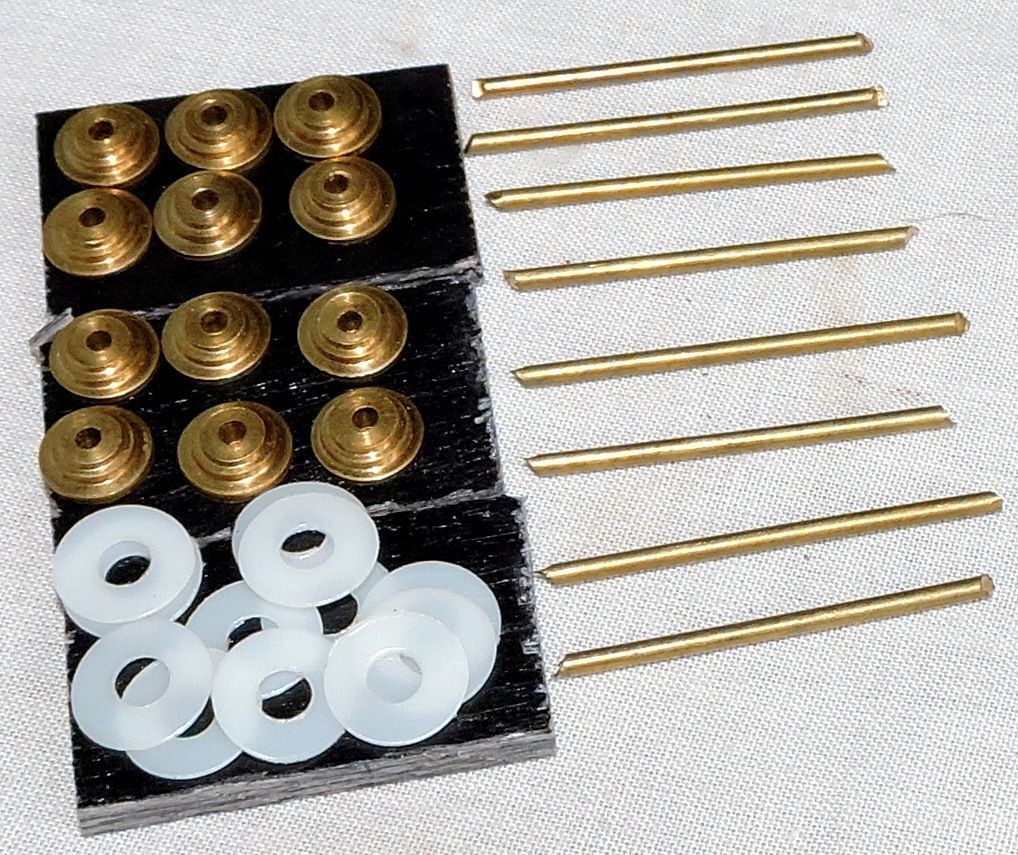

This is the outcome of two half days of scale making for new shorty blade.

Other than that it was a project which was coming along reasonably well. Slowly, but coming along.

I don't know that I did anything wrong, but I'll think about it.

It is not the end of the world. It doesn't even ruin my day. Still, you can imagine that I'm not a happy camper concerning this event.

The scales themselves were fine until suddenly they weren't.

Happy shaves,

Jim

Other than that it was a project which was coming along reasonably well. Slowly, but coming along.

I don't know that I did anything wrong, but I'll think about it.

It is not the end of the world. It doesn't even ruin my day. Still, you can imagine that I'm not a happy camper concerning this event.

The scales themselves were fine until suddenly they weren't.

Happy shaves,

Jim