Thanks. I'll certainly get a copy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Made in China!

- Thread starter rbscebu

- Start date

Here’s a story that really illustrates the Japanese culture. When an internal combustion engine is designed, one of the more important decisions a designer must make involves the intake and exhaust valves. Like many of these decisions, there are a lot of trade-offs that must be considered. In the 1920s, experiments were carried out that had proven a small number of the largest diameter valves possible enabled an engine to run more efficiently and produce more power. Those experiments were accepted as the gospel on valve-train design for almost 50 years, and during that time, the entire world focused on developing engines with two large-diameter valves per cylinder. In the 1960s, the Japanese showed up on the motorcycle racing circuit with their newly designed engines. Low and behold, they all had a very large number of very small valves in their internal combustion engines. Exactly the opposite approach that had been proven correct in the 20s, and used by the entire world since then. The entire world laughed at the Japanese. Engine designers in Japan were stuck so far back in the dark ages that they hadn’t even heard about those British experiments that were the standard for almost 50 years. Then the races began, and the Japanese started winning. Consistently, and not by small margins. It turned out that the entire world was in the dark, and the Japanese were the enlightened ones. The Japanese ignored the earlier experiments and did their own which proved the early British experiments only applied at very low engine RPM. That was fine in the 1920s, but was completely wrong for the high RPM motorcycle engines that were common in the 1960s. The Japanese had proven that at high RPM, valve mass was much more important than flow efficiency. Even though a larger number of small valves doesn’t let an engine breath as efficiently, it reduced valve mass and that lets the designer spin the engine much faster. That increase in engine speed more than makes up for the reduction in flow efficiency and enables the engine to produce significantly more power. It took the rest of the world more than 20 years to catch up to Japanese valve-train design. Now, it’s pretty much standard that an engine will have multiple small valves per cylinder, but that is entirely due to Japanese innovation. This is one reason the Japanese make great quality products. Innovation is in their culture.

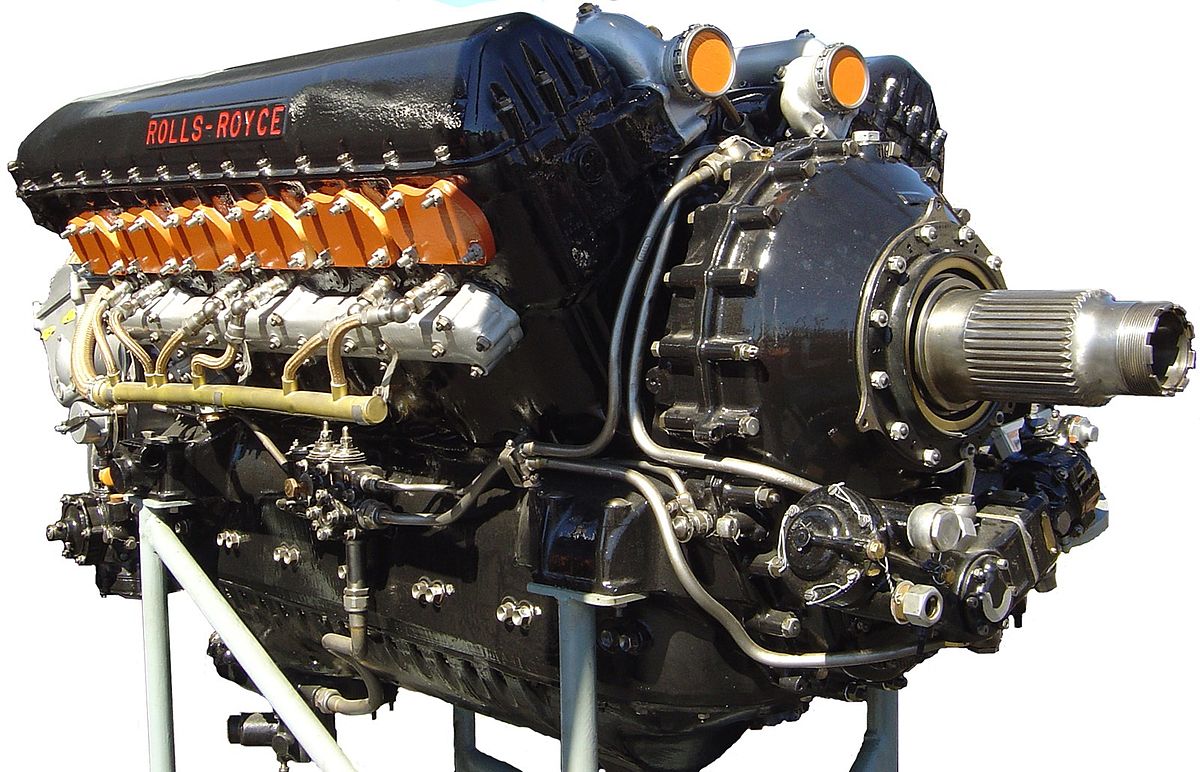

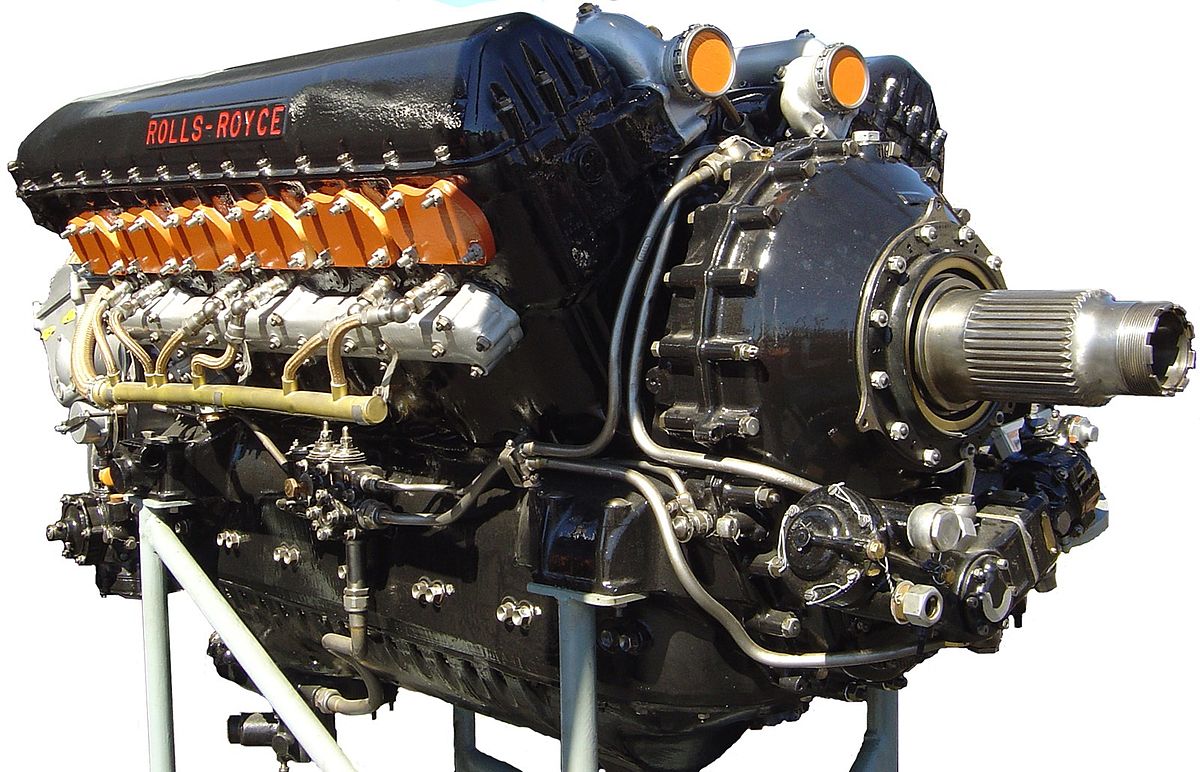

Rolls Royce Merlin engine was a V12, overhead cam, 4 valves per cylinder. 1933 engineering. Predated the Japanese multi-valve engineering by 30 years.

Rolls-Royce Merlin - Wikipedia

one of my favorites from the late, great Ox.

China can already produce really high end quality. But mostly they are commissioned for as cheap as possible stuff.

Anyhow, I feel that there will never again be a time of easy labels. There might be american made crap and chinese high end, nether easily identified by a simple label.

just my 2ct

godek

Anyhow, I feel that there will never again be a time of easy labels. There might be american made crap and chinese high end, nether easily identified by a simple label.

just my 2ct

godek

Rolls Royce Merlin engine was a V12, overhead cam, 4 valves per cylinder. 1933 engineering. Predated the Japanese multi-valve engineering by 30 years.

Rolls-Royce Merlin - Wikipedia

en.m.wikipedia.org

I didn't say that multi-valve engines never existed before the Japanese worked with them. Certainly, large displacement engines have the room to use multiple valves per cylinder, but multiple valves in that case serve a completely different purpose. It's not to reduce valve-train mass and spin the engine faster. The point of the story is that they were not common at all, and certainly weren't common on smaller engines for autos and motorcycles. The people designing engines for autos and motorcycles went in a different direction, and that turned out to be inferior.

The overall point of the story is that Japan was an innovator, and there's very little innovation coming out of China in comparison. If China is going to become a world-class developer of products, like the Japanese have been, it's very unlikely they will be taking the same pathway that the Japanese took. It's likely to be a path that is completely unrelated. And just because the Japanese became world class developers of products does not mean that the Chinese will.

shavefan

I’m not a fan

China=Excellence at producing all sort of new viruses...

Wonder if they'll make a corona razor.

I don’t know, but they are good at Kung Flu.Wonder if they'll make a corona razor.

China makes great portable radios. I use my 18650 powered Tecsun ICR-110 every day running my SD card mp3 playlist.

I think china makes cheap stuff, and I mean CHEAP in the whole sense of the word! The reason some good stuff comes from china is NOT because they designed it....it's just because greedy 1st world companies want to make more money and take advantage of the chinese sweat shops.....

Besides my apple products that soon will be made in the US.....I would gladly forgo ALL chinese products..... they can keep their cheap stuff and their mutating animal virus, too. And Corona is a beer , not a chinese zoonotic virus....

Besides my apple products that soon will be made in the US.....I would gladly forgo ALL chinese products..... they can keep their cheap stuff and their mutating animal virus, too. And Corona is a beer , not a chinese zoonotic virus....

I think people forget that some high end products are made in china. Apple products for example. iPhones are made in china.

BMW and KTM motorcycles are using Chinese engines in their smaller capacity machines.

Yes. I agree that china is where Japan was several decades ago but things are changing rapidly.

BMW and KTM motorcycles are using Chinese engines in their smaller capacity machines.

Yes. I agree that china is where Japan was several decades ago but things are changing rapidly.

- Thread starter

- #32

rbscebu

Girls call me Makaluod

Don't believe everything that your mass media feeds you. Go to China and try and find their "sweat shops" making goods for western markets. I have spent years working in China and it is nothing like what your mass media feeds you..... take advantage of the chinese sweat shops. ....

Yes= Greed. They will soon move to Vietnam in search for cheaper labour.I think people forget that some high end products are made in china. Apple products for example. iPhones are made in china.

BMW and KTM motorcycles are using Chinese engines in their smaller capacity machines.

Yes. I agree that china is where Japan was several decades ago but things are changing rapidly.

Will I ever buy a chinese car: NeVeR.

A watch: besides the one casio I got, none

Greedy Apple moving production to US.

I am currently bringing a new, molded part to market. I plan to NEVER have any manufacturing done in China. They likely will want to knock off the part, but why make it any easier for them by supplying them with the CAD files, etc?

Made in the USA, baby!

Made in the USA, baby!

They also make great flashlights / torches.

I think it is important to realize designing and actually building something are two things.

Chinese can do both. For now they suck at designing things where they have no clue of the actual use. But this is going to change, too.

Manufacturing in a globalized environment means that you shop for the lowest bidder. For most things you end up in China, but AFIAK clothes like t-shirts have already been moved to Vietnam.

People need to learn how important QC is. When the manufacturer is two continents away you need a different quality culture then when the production is down the hall and you have lunch with the guys every day.

QC costs money. QC for stuff made far away is more complicated and costs more money. But it can be done.

QC means that an in-house department finds the defects, not the customers.

A lesson Occam's / Classic shaving is getting right now.

I work in QA in a software development company. Slowly developers are realizing that QA is not the evil. Yes, we point out all the flaws in the software. But we also enable them to make their stuff better.

br

godek

Chinese can do both. For now they suck at designing things where they have no clue of the actual use. But this is going to change, too.

Manufacturing in a globalized environment means that you shop for the lowest bidder. For most things you end up in China, but AFIAK clothes like t-shirts have already been moved to Vietnam.

People need to learn how important QC is. When the manufacturer is two continents away you need a different quality culture then when the production is down the hall and you have lunch with the guys every day.

QC costs money. QC for stuff made far away is more complicated and costs more money. But it can be done.

QC means that an in-house department finds the defects, not the customers.

A lesson Occam's / Classic shaving is getting right now.

I work in QA in a software development company. Slowly developers are realizing that QA is not the evil. Yes, we point out all the flaws in the software. But we also enable them to make their stuff better.

br

godek

Similar threads

- Replies

- 18

- Views

- 5K

- Replies

- 21

- Views

- 5K