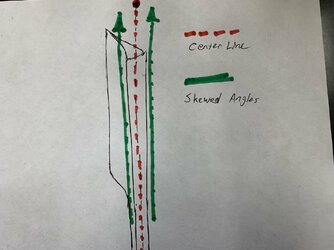

I’ve noticed it on a good number of my razors there’s a slight taper in regards to the spine width. I’ve noticed a thinner measurement towards the heel versus the toe. Please refer to the attached illustration. My thought is that this will inevitably create a lot of difficulty in regards to the Bevel planes meeting at a true point throughout the length of the bevel. Any thoughts?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Left and right side of the spine not parallel to the center line. Any thoughts?

- Thread starter lightfoot

- Start date

Might need more info regarding the type of razor.

They are hand ground, and some are done on Monday morning…

They are hand ground, and some are done on Monday morning…

- Thread starter

- #3

Well, keep in mind that may have introduced some of this tapered wear unknowingly throughout the time that I’ve used these blades…Might need more info regarding the type of razor.

They are hand ground, and some are done on Monday morning…

All French razors I own have this shape if you look hard enough when new.I’ve noticed it on a good number of my razors there’s a slight taper in regards to the spine width. I’ve noticed a thinner measurement towards the heel versus the toe. Please refer to the attached illustration. My thought is that this will inevitably create a lot of difficulty in regards to the Bevel planes meeting at a true point throughout the length of the bevel. Any thoughts?

I think it is a combination of the forging and grinding.

I don't know much about razor forging. But I think the French blanks are forged differently then the German. All my German razors have more of a uniform warp on one side. One vs two, maybe three drop forging.

If the razor is honed like it is straight on a flat stone you might end up with uneven taper from one side relative to the other side.

If the initial bevel is cut with a spinning disk, you will have a tendency to apply more pressure closer to the grip. The lever arm will get longer as you approach the tip, resulting in a smaller downward force. This will grind the spine thinner closer to the pivot pin.

Last edited:

- Thread starter

- #5

My question really has to do with how this could impact the formation of a good bevel. If the bevel is an echo of the parallism of the spine (or lack there of) then I would think the lack of parallel at the spine has to be reflected at the bevel.All French razors I own have this shape if you look hard enough when new.

I think it is a combination of the forging and grinding.

I don't know much about razor forging. But I think the French blanks are forged differently then the German. All my German razors have more of a uniform warp on one side. One vs two, maybe three drop forging.

If the razor is honed like it is straight on a flat stone you might end up with uneven taper from one side relative to the other side.

For example a Feather Artist Club blade will have total uniformity and thickness. We don’t necessarily have that with most straight razors perhaps?

Last edited:

I agree that this can make a difference in the bevels. Meaning not being exactly the same. But in the case of shave-ability, it won't matter. So many razors are ground funky. A lot worse than a bit of center. And they still shave fine. Bevel grinding is done by hand. A perfect hollow on both sides that match perfectly would be hard to do. Or at a minimum, the Grinder would need to care more and not think about production numbers.

Tapered spine- the spine thickness relative blade width should be the same throughout the length of blade. Measure spine thickness and width of blade and calculate honing angle in toe, middle and heel area and compare.

But of course you are right, if it doesn't match rolling x-stroke or a narrow/side wise convex hone need to be used to manage the honing. Or the thickness of the spine can be corrected.

If it's more common that manufactured tapered blades are less symmetrical in spine relative blade area- don't know.

If it's more common that manufactured tapered blades vary in the relation spine thickness- width of blade along blade length- don't know but guess yes.

On top of spine thickness not matching the width of blade all length of the blade, the blade can also be curved in banana shape lengthwise. But you already know this.

But of course you are right, if it doesn't match rolling x-stroke or a narrow/side wise convex hone need to be used to manage the honing. Or the thickness of the spine can be corrected.

If it's more common that manufactured tapered blades are less symmetrical in spine relative blade area- don't know.

If it's more common that manufactured tapered blades vary in the relation spine thickness- width of blade along blade length- don't know but guess yes.

On top of spine thickness not matching the width of blade all length of the blade, the blade can also be curved in banana shape lengthwise. But you already know this.

Last edited:

rbscebu

Girls call me Makaluod

@lightfoot, the question you ask really boils down to are your SRs still shaving well?

- Thread starter

- #9

Well I took three razors That demonstrated a little variation in spine width from heel to toe that seem to hone up inconsistently. All of these blades measured a little wider at the toe and for some reason. Of course I’m talking about the width of the spine. So I added a small area of tape back at the heel of these razors to get the width to even out and all of a sudden they were shaving great. That being said this doesn’t necessarily “prove” anything per se. If I had only seen good results on one out of three of these razors I could’ve dismissed it but what actually happened is I experienced a significant improvement during the shave in all three cases.@lightfoot, the question you ask really boils down to are your SRs still shaving well?

Slash McCoy

I freehand dog rockets

You are looking for absolute consistency and perfection in matters that do not affect the shave at all. The only thing that really matters is that there is a bevel facet on either side of the razor at the edge. and both faces intersect in a good edge. The width of the bevel face does not matter. Symmetry does not matter. Consistent bevel face width does not matter. Consistent spine thickness does not matter. A bevel. That's all that matters. When the razor will not support a bevel face on both sides of the edge, you have a problem. When you have a frown, especially a severe one, you have a problem. If there is enough steel, practically all grind or warp or twist or taper issues can be corrected.

It is reasonable to expect a very high degree of consistency and symmetry on a very expensive razor. Common work-a-day razors, not so much. Entry level or below, be very surprised indeed if everything is perfect in geometry and cosmetics. Vintage razors are all over the road, from multiple "I got this" guys honing on whatever they have for honing with. It's not always the factory grind at fault.

Honing a slightly wonky razor isn't really that much different from honing a perfect razor. Just hone normally on a normal honing surface with a normal slight x stroke or if needed, a bit of a rolling x stroke, and see what happens. Sharpie. Loupe. Bright work light. Change in grits or honing direction, so you can see exactly where steel is coming off or steel is not touching hone. Analyze. Adjust pressure and adjust balance of pressure as needed to gradually bring the entire bevel into hone contact. If you are honing on a bench, try honing in hand. Let the razor and hone find their alignment instead of forcing it with two hands on the razor.

If the razor is shaving just fine, maybe you can keep doing exactly as you are. Examine. Monitor. If your razor's symmetry and geometry are getting worse with your honing, then you may have a problem, but nothing you can't fix. Otherwise, carry on, and enjoy your shaves. In other words, if it ain't broke, don't break it.

It is reasonable to expect a very high degree of consistency and symmetry on a very expensive razor. Common work-a-day razors, not so much. Entry level or below, be very surprised indeed if everything is perfect in geometry and cosmetics. Vintage razors are all over the road, from multiple "I got this" guys honing on whatever they have for honing with. It's not always the factory grind at fault.

Honing a slightly wonky razor isn't really that much different from honing a perfect razor. Just hone normally on a normal honing surface with a normal slight x stroke or if needed, a bit of a rolling x stroke, and see what happens. Sharpie. Loupe. Bright work light. Change in grits or honing direction, so you can see exactly where steel is coming off or steel is not touching hone. Analyze. Adjust pressure and adjust balance of pressure as needed to gradually bring the entire bevel into hone contact. If you are honing on a bench, try honing in hand. Let the razor and hone find their alignment instead of forcing it with two hands on the razor.

If the razor is shaving just fine, maybe you can keep doing exactly as you are. Examine. Monitor. If your razor's symmetry and geometry are getting worse with your honing, then you may have a problem, but nothing you can't fix. Otherwise, carry on, and enjoy your shaves. In other words, if it ain't broke, don't break it.

- Thread starter

- #11

So I was actually very apprehensive to post this thread at all. But it is a forum and disagreement is definitely to be expected and understandably so. I think if you refer to my diagram in the very first post you will get a very clear idea of why you may not in fact have a good bevel intersection at the Apex.You are looking for absolute consistency and perfection in matters that do not affect the shave at all. The only thing that really matters is that there is a bevel facet on either side of the razor at the edge. and both faces intersect in a good edge. The width of the bevel face does not matter. Symmetry does not matter. Consistent bevel face width does not matter. Consistent spine thickness does not matter. A bevel. That's all that matters. When the razor will not support a bevel face on both sides of the edge, you have a problem. When you have a frown, especially a severe one, you have a problem. If there is enough steel, practically all grind or warp or twist or taper issues can be corrected.

It is reasonable to expect a very high degree of consistency and symmetry on a very expensive razor. Common work-a-day razors, not so much. Entry level or below, be very surprised indeed if everything is perfect in geometry and cosmetics. Vintage razors are all over the road, from multiple "I got this" guys honing on whatever they have for honing with. It's not always the factory grind at fault.

Honing a slightly wonky razor isn't really that much different from honing a perfect razor. Just hone normally on a normal honing surface with a normal slight x stroke or if needed, a bit of a rolling x stroke, and see what happens. Sharpie. Loupe. Bright work light. Change in grits or honing direction, so you can see exactly where steel is coming off or steel is not touching hone. Analyze. Adjust pressure and adjust balance of pressure as needed to gradually bring the entire bevel into hone contact. If you are honing on a bench, try honing in hand. Let the razor and hone find their alignment instead of forcing it with two hands on the razor.

If the razor is shaving just fine, maybe you can keep doing exactly as you are. Examine. Monitor. If your razor's symmetry and geometry are getting worse with your honing, then you may have a problem, but nothing you can't fix. Otherwise, carry on, and enjoy your shaves. In other words, if it ain't broke, don't break it.

Is it possible that these two angles “cross” each other at the apex rather than meeting at a point?

Last edited:

Question. On these razors where the spine tapers from toe to heel, is the blade width the same from toe to heel, or does it get narrower at the heel? I ask because older Swedish razors, framebacks especially, often are wider at the toe than the heel. (and as often as not have a slightly upturned toe that appears in many cases to have been designed that way, not honed into that shape). Now, some of these, the spine will taper in proportion to the blade width, which makes them pretty easy to hone. But not always. Ones where the spine is a consistent width, they're still honeable, but you do have to accentuate the rolling x-stroke to hit the edge consistently, much like you would with a razor that has a much more significant smile.

In my opinion, as long as the spine tapers gradually, it's not a problem regardless of how the blade width relates to the spine thickness-- but you do have to compensate for it in your honing stroke.

In my opinion, as long as the spine tapers gradually, it's not a problem regardless of how the blade width relates to the spine thickness-- but you do have to compensate for it in your honing stroke.

- Thread starter

- #13

So one of the three is a French frame back that has the most significant taper. And yes the blade width his wider at the toe end which also has the thicker spine width and reduces down the length of the razor. I could definitely see this being able to maintain a consistent bevel angle down the length of the razor. But the other two are just generic German blades that have a consistent blade width from heel to toe. But in regards to the German blade the taper is very minimal. That being said there was a significant improvement in the end result when I artificially equalized the spine with with a small area of tape back at the heel. I wasn’t concerned with correcting the spine width per se but rather creating the effect of parallelism so that would be reflected at the Bevel. Is it possible that I’m over thinking? Yes. But these are blades with essentially no value to speak of and so it made for a fun thought experiment.Question. On these razors where the spine tapers from toe to heel, is the blade width the same from toe to heel, or does it get narrower at the heel? I ask because older Swedish razors, framebacks especially, often are wider at the toe than the heel. (and as often as not have a slightly upturned toe that appears in many cases to have been designed that way, not honed into that shape). Now, some of these, the spine will taper in proportion to the blade width, which makes them pretty easy to hone. But not always. Ones where the spine is a consistent width, they're still honeable, but you do have to accentuate the rolling x-stroke to hit the edge consistently, much like you would with a razor that has a much more significant smile.

In my opinion, as long as the spine tapers gradually, it's not a problem regardless of how the blade width relates to the spine thickness-- but you do have to compensate for it in your honing stroke.

Last edited:

That makes sense, you can hit the whole edge without as much in the way of honing gymnastics.That being said there was a significant improvement in the end result when I artificially equalized the spine with with a small area of tape back at the heel.

If you got a more even bevel and a more consistent bevel angle on each side by adding tape on part of the spine you are at least making the honing easier by reducing some variables.So I was actually very apprehensive to post this thread at all. But it is a forum and disagreement is definitely to be expected and understandably so. I think if you refer to my diagram in the very first post you will get a very clear idea of why you may not in fact have a good bevel intersection at the Apex.

Is it possible that these two angles “cross” each other at the apex rather than meeting at a point?

An uneven bevel will in itself not make any difference in the shave, but working with a bevel that develops at different rates along the blade and from side to side is challenging. It might be easier to do as much of the bevel correction as possible on the spine, either by using tape or by honing the spine.

Slash McCoy

I freehand dog rockets

I am not really sure I understand the difference. If they cross, then they must meet.So I was actually very apprehensive to post this thread at all. But it is a forum and disagreement is definitely to be expected and understandably so. I think if you refer to my diagram in the very first post you will get a very clear idea of why you may not in fact have a good bevel intersection at the Apex.

Is it possible that these two angles “cross” each other at the apex rather than meeting at a point?

When you hone the razor, does the bevel make good contact, and are you getting a good edge? Are you getting a good shave?

Knowledge doesn't exist in a vacuum. Discussion is important for furthering our collective skill set. You shouldn't feel reluctant to post a sincere question or a genuine problem or even a purely theoretical question. I hope you don't think anything I wrote was meant to shut you down. That would be the last thing I would want to do to a valued and productive member of the forum.

- Thread starter

- #17

Ok so if you’re open to an entirely theoretical idea then if the bevel is a reflection of the spine and each side of the spine that contacts the stone is slightly pitched a bit off center then each respective side of the bevel would be at slightly opposite angles which theoretically would kind of form an “X” at the bevel. This is just some I’ve wondered about for a while…I am not really sure I understand the difference. If they cross, then they must meet.

When you hone the razor, does the bevel make good contact, and are you getting a good edge? Are you getting a good shave?

Knowledge doesn't exist in a vacuum. Discussion is important for furthering our collective skill set. You shouldn't feel reluctant to post a sincere question or a genuine problem or even a purely theoretical question. I hope you don't think anything I wrote was meant to shut you down. That would be the last thing I would want to do to a valued and productive member of the forum.

So with a taper narrowing towards the heel (just for example) one could wind up with a slightly under honed toe (if you weren’t paying close attention), a balanced apex in the middle, and slightly more wear at the heel end.

I’m not saying that it’s impossible to hone past the disagreeing angles but they would be there for sure.

I took some measurements with the micrometer I keep at home (I have digital but I left it at work) and there’s a difference from heel to toe but without my digital mic. I can’t post specifics.

The impetus for looking closely at this is repeatedly inconsistent results on a few razors.

So I’m not trying to pitch the idea that this is something we should all be checking for but rather I’m just posting my findings which for some reason seemed to yield a pretty immediate improvement once the slight variance was noted and compensated for. But my perception of an improvement could be more imagined than real of course.

Not really that unusual. It is much like what happens when one hones on the stabilizer, it lifts the heel off the stone or at least keep the bevel from making full contact.

Many old razors have had the stabilizer ground flat from years of honing, but the bevels are all wonky. Though some are “shaveable”.

If the heel is corrected and the corner moved well away from the stabilizer taking it out of play, the bevels straighten out and a more uniform, straighter edge is made. You are doing the same thing but instead of removing steel you add tape to make a straighter spine and edge.

Probably your bevels were making contact, but not fully contact to the edge, or grinding bevels at two different angles.

If you look at an issue and ask why it is occurring and try to figure out a solution, it is always better than just muscling through it, doing more of the same.

There are no rules.

Many old razors have had the stabilizer ground flat from years of honing, but the bevels are all wonky. Though some are “shaveable”.

If the heel is corrected and the corner moved well away from the stabilizer taking it out of play, the bevels straighten out and a more uniform, straighter edge is made. You are doing the same thing but instead of removing steel you add tape to make a straighter spine and edge.

Probably your bevels were making contact, but not fully contact to the edge, or grinding bevels at two different angles.

If you look at an issue and ask why it is occurring and try to figure out a solution, it is always better than just muscling through it, doing more of the same.

There are no rules.

Steve56

Ask me about shaving naked!

If you look at an issue and ask why it is occurring and try to figure out a solution, it is always better than just muscling through it, doing more of the same.

That’s pretty much what corrective honing is.

There are exceptions though. Sometimes you don’t really want to correct some wear issues though. If a razor has been honed at an angle to the stone, like 45 degrees, the razor spine above the heel will become thicker over the years because it isn’t on the hone, and the spine will become tapered. This is called a distal taper in the knife world and is an elegant and desirable thing because it’s usually done by hand and reduces the knife weight. Alas, not so for straight razors. See images below, you can see the spine taper on the Wade and Butcher.

The best thing that you can do with these is hone them the same way that they were for the past century or so, grinding the spine flat and resetting the bevel would destroy the appearance of the razor, remove too much metal, and make it worthless

- Thread starter

- #20

So you’re saying honing toe-forward will offset the kind of taper being discussed here? If so that’s great info for sure.That’s pretty much what corrective honing is.

There are exceptions though. Sometimes you don’t really want to correct some wear issues though. If a razor has been honed at an angle to the stone, like 45 degrees, the razor spine above the heel will become thicker over the years because it isn’t on the hone, and the spine will become tapered. This is called a distal taper in the knife world and is an elegant and desirable thing because it’s usually done by hand and reduces the knife weight. Alas, not so for straight razors. See images below, you can see the spine taper on the Wade and Butcher.

The best thing that you can do with these is hone them the same way that they were for the past century or so, grinding the spine flat and resetting the bevel would destroy the appearance of the razor, remove too much metal, and make it worthless

View attachment 1495766View attachment 1495768. Honing a razor with a tapered spine at 90 degrees vs the illustrated 45 degrees will cut a different bevel and tilt the heel up just like honing on the stabilizer.

Similar threads

- Article

- Replies

- 11

- Views

- 2K

- Replies

- 23

- Views

- 4K